- Top: 2511Step on: 35971

système d'extraction des fumées de soudage

People involved | Date:2025-08-14 10:37:08

Related articles

- Fume Extraction Arms These flexible arms are often mounted on the ceiling or on a standalone frame. They can be positioned close to the welding area to capture fumes at their source.

The integration of welding arms with effective fume extraction systems is a game-changer in advanced fabrication. As industries continue to embrace robotic welders for complex projects, the ability to maintain clean air and a safe environment becomes just as critical as the welding process itself. With flexible options like mobile welding fume extractors and robust fume exhaust systems, manufacturers can improve productivity without compromising on safety.

An industry-specific example of successful implementation can be seen within the automotive sector, where these machines are used extensively to apply anti-corrosive coatings and finish paints. Companies report a marked improvement in productivity and product quality, with coatings displaying superior durability and aesthetic appeal. This real-world application highlights the transformative impact of automatic spray coating machines, proving their value beyond theoretical benefits.

Welding Exhaust Arm: Key to Clean and Safe Work Environments

- - Electrostatic Spray This technique uses electrical charges to attract paint particles to the surface being coated, resulting in a more uniform application with minimal overspray.

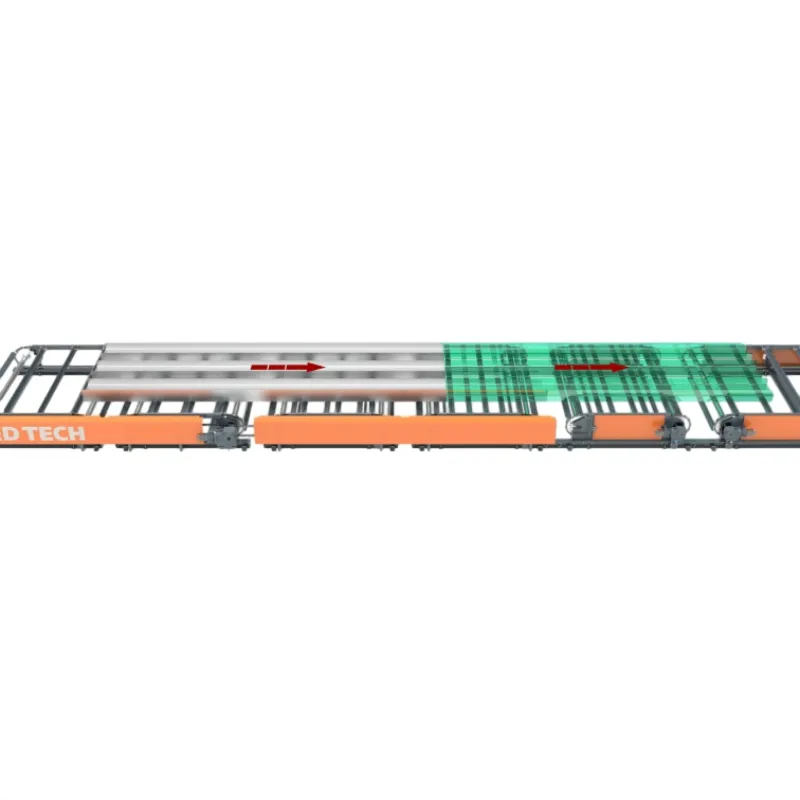

The integration of steel structure manufacturing equipment with automatic spray painting systems has transformed how manufacturers handle large-scale production. These machines provide consistent and even coatings, ensuring that every piece meets stringent quality standards.

The use of steel structures also enhances the adaptability of spraying lines, allowing manufacturers to customize their setups based on specific production needs. For example, a well-designed steel structure can accommodate various configurations, making it easier to integrate additional equipment or expand the line as production demands grow. The robustness of steel ensures long-term reliability, minimizing maintenance requirements and downtime.

5. Health Surveillance Implementing health surveillance programs for welders can help detect early signs of health issues related to weld smoke exposure. Regular check-ups and screenings can facilitate early intervention and contribute to better long-term health outcomes.

The Extraction of the Gulf An Exploration of Coastal Development

These boots, therefore, not only equip children with functional shoes but also foster a connection with the outdoors These boots, therefore, not only equip children with functional shoes but also foster a connection with the outdoors

These boots, therefore, not only equip children with functional shoes but also foster a connection with the outdoors These boots, therefore, not only equip children with functional shoes but also foster a connection with the outdoors

Today, they are available in a wide range of styles and designs, from classic wellington boots to more fashionable options that can be worn with a variety of outfits Today, they are available in a wide range of styles and designs, from classic wellington boots to more fashionable options that can be worn with a variety of outfits

Today, they are available in a wide range of styles and designs, from classic wellington boots to more fashionable options that can be worn with a variety of outfits Today, they are available in a wide range of styles and designs, from classic wellington boots to more fashionable options that can be worn with a variety of outfits

They pair perfectly with skinny jeans, leggings, or even dresses and skirts, transforming rainy day outfits into fashionable ensembles They pair perfectly with skinny jeans, leggings, or even dresses and skirts, transforming rainy day outfits into fashionable ensembles

They pair perfectly with skinny jeans, leggings, or even dresses and skirts, transforming rainy day outfits into fashionable ensembles They pair perfectly with skinny jeans, leggings, or even dresses and skirts, transforming rainy day outfits into fashionable ensembles

Comment area