- Top: 72Step on: 7472

Shijiazhuang TangChao Metal black craft wire

People involved | Date:2025-08-14 03:37:53

Related articles

1. Improved Air Quality The primary advantage of using portable ventilation systems is the significant improvement in air quality. By effectively removing fumes and contaminants, these systems protect the health of welders.

5. Safety and Ergonomics By automating the spray coating process, manufacturers can minimize the exposure of workers to hazardous materials and fumes associated with manual spraying, leading to a safer working environment.

Welding is an indispensable process in various industries, but the associated health risks from welding fumes are significant. An efficient fume extraction system plays a vital role in protecting workers from harmful exposure, thereby promoting occupational safety and health. By investing in an appropriate system and fostering a culture of safety, employers not only safeguard their workforce but also enhance productivity and contribute to a healthier work environment overall. As industries evolve and regulations tighten, prioritizing fume extraction systems will be crucial in ensuring the well-being of welders and the sustainability of welding operations.

The impact of automated spray coating systems extends beyond efficiency. These systems contribute to sustainability by optimizing material usage, reducing emissions, and ensuring safer plant environments due to reduced operator exposure to harmful chemicals. The advancement of eco-friendly coatings and biodegradable materials further aligns these systems with global sustainability goals.

An automatic spray painting machine project is a tailored solution designed to improve efficiency and reduce manual labor in industrial coating applications. These machines automate the entire painting process, ensuring precision in every coat. Industries such as automotive, furniture, and construction rely on these systems to handle high-volume production without compromising quality.

The use of high-quality fume extraction equipment means that the welding process can continue uninterrupted, without the need to pause for safety concerns or poor air quality. This contributes to the continuous and flawless operation of automated welding arms, reducing downtime and ensuring that every weld is perfect.

Achieving Superior Coatings Through Steel Structure Painting

Ultimately, the decision to employ an automatic spray painting machine is one that underscores a commitment to quality, efficiency, and forward-thinking production strategies. Not only does it signify an alignment with cutting-edge technology, but it also positions your business as a leader in delivering products that meet high standards in craftsmanship and environmental consideration.

Steel structure painting is essential for maintaining the integrity and aesthetic appeal of buildings, bridges, and other infrastructure. As cities and industries continue to grow, the demand for reliable, sustainable solutions for steel protection will remain high, ensuring that painted steel structures stand the test of time.

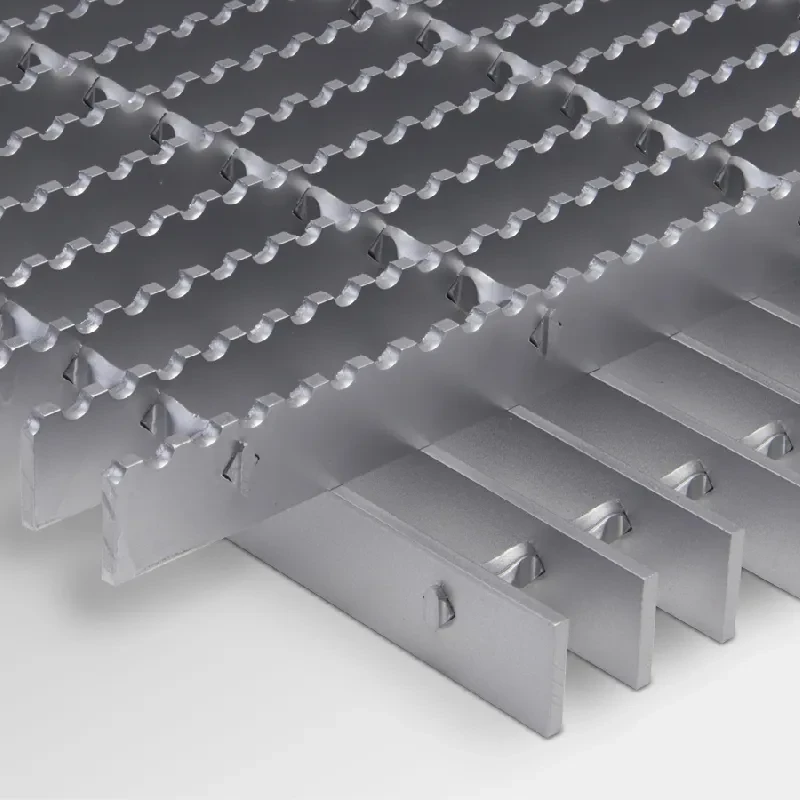

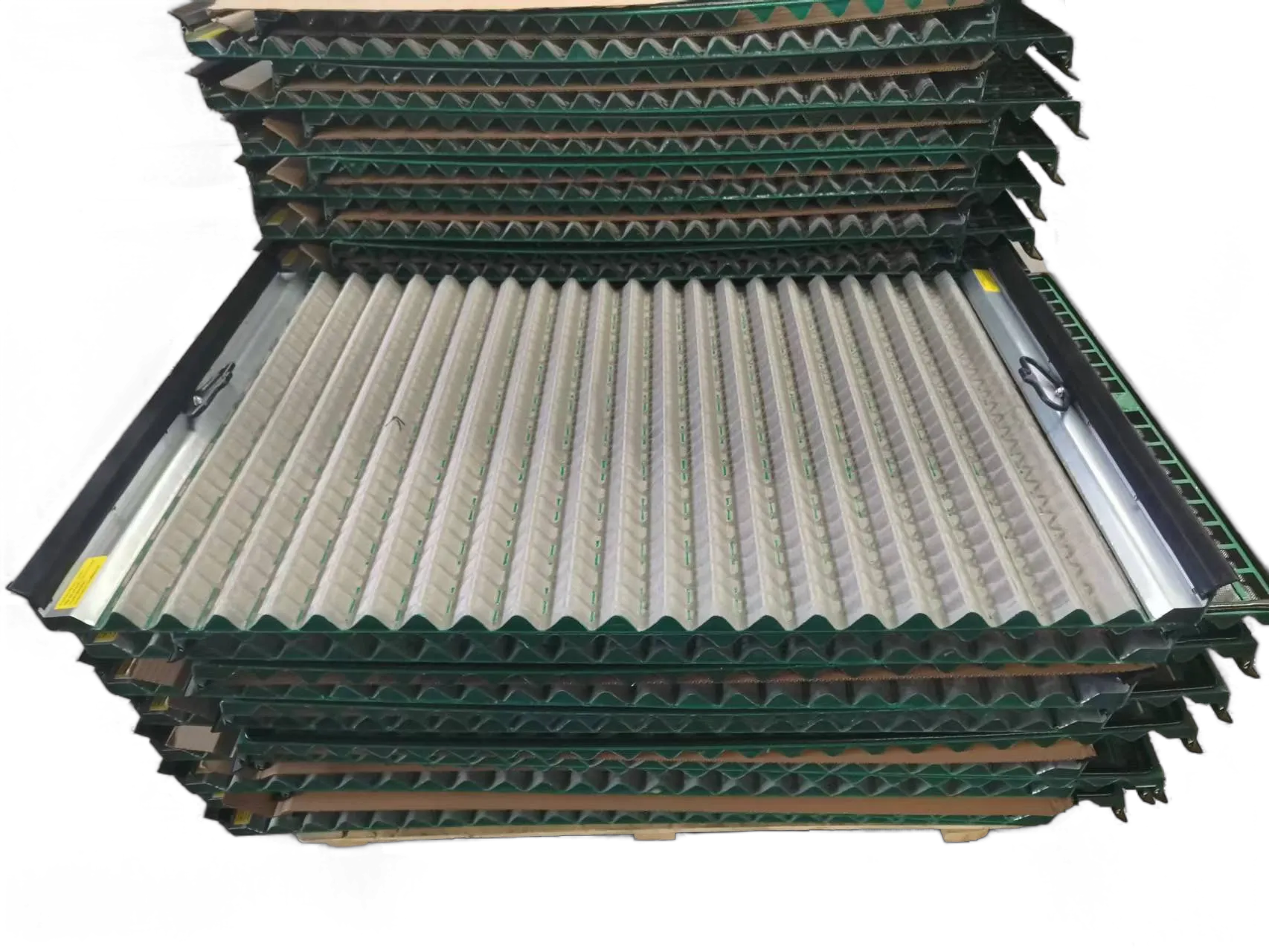

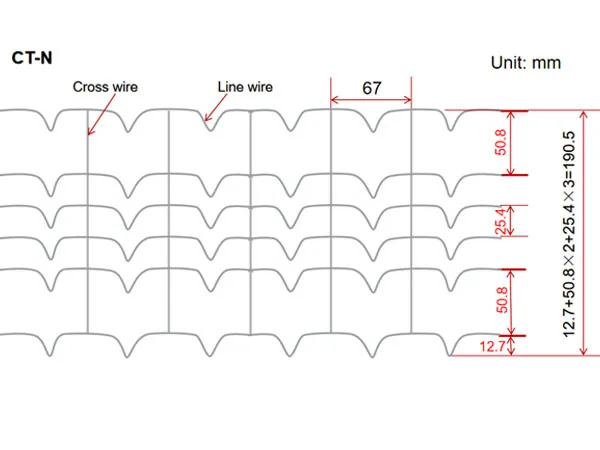

A steel floor system comprises various components, including steel beams, girders, and decking, which together support the floor of a building. The primary role of this system is to distribute loads effectively while providing a durable and stable platform. The steel can be used in various forms, such as composite steel-concrete floors or steel joists, allowing for flexibility in design and architecture.

Comment area