- Top: 176Step on: 351

Shijiazhuang TangChao Metal galvanized steel stucco netting

People involved | Date:2025-08-14 04:37:26

Related articles

Authority in this domain is often derived from understanding regulatory standards and their implications for equipment technology. Automatic paint spraying systems not only comply with these standards but also make it easier for companies to meet stringent environmental regulations. By reducing volatile organic compound (VOC) emissions, they bolster a company’s commitment to sustainable practices. As an adviser to environmental compliance teams, I can attest that businesses integrating these machines have experienced smoother audits and an enhanced reputation for sustainability.

The primary advantage of using an automatic spray coating machine lies in its ability to deliver consistent results. Unlike manual spraying methods, these machines ensure that every inch of the surface receives an identical amount of coating, minimizing human error, and wastage of materials. This uniformity is particularly important when dealing with large production volumes or intricate surfaces, where manual spraying would lead to inconsistencies.

Improving Workplace Safety with Smoke Eaters for Welding

Cultural Significance

One of the key advancements accompanying this shift is the incorporation of welding extraction units. These units work in tandem with robotic welding systems, ensuring that harmful fumes and particles are immediately captured at the source.

Meeting Diverse Needs with Automatic Paint Spray Machines

Precision and Consistency in Steel Component Spray Painting

Technological advancements have significantly transformed container loading platforms over the years. Automation is at the forefront of this evolution. Automated stacking cranes, for instance, can load and unload containers without the need for human intervention. This not only reduces labor costs but also improves safety by minimizing human error – a leading cause of accidents in busy freight environments.

There are several types of ventilation systems that can be employed in robotic welding environments

. Each system has its advantages and is suited to different application needs.

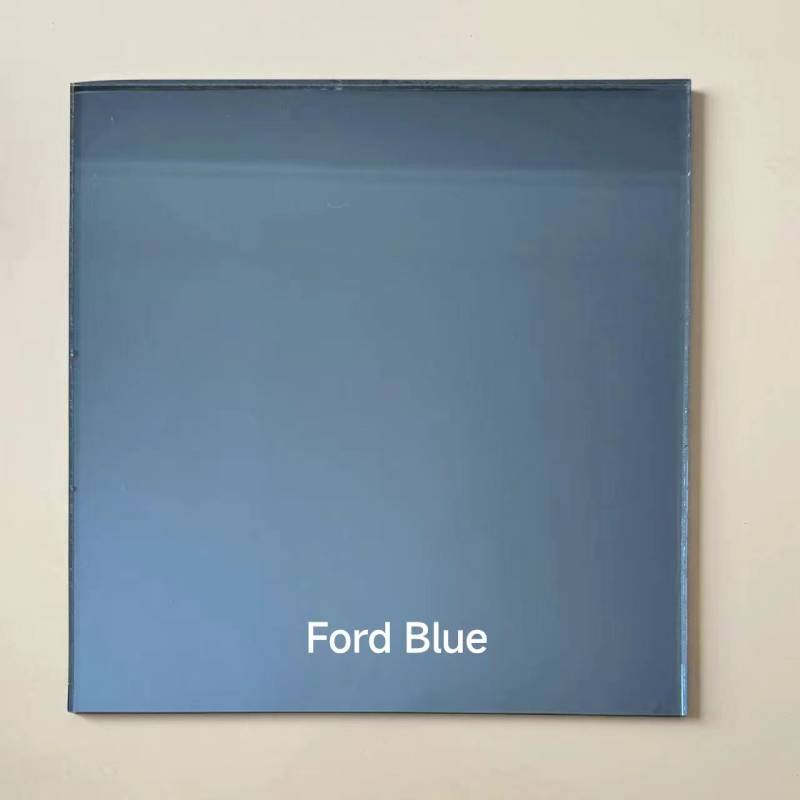

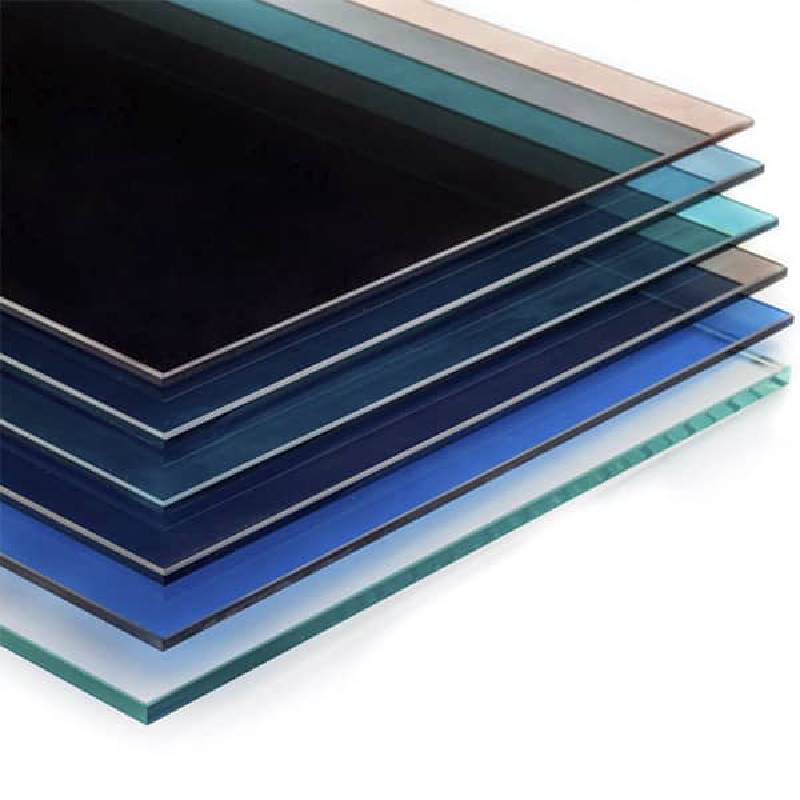

It also provides a degree of noise reduction, creating a tranquil living or working environment It also provides a degree of noise reduction, creating a tranquil living or working environment

It also provides a degree of noise reduction, creating a tranquil living or working environment It also provides a degree of noise reduction, creating a tranquil living or working environment Mirrors are known for their ability to make a room feel more spacious and airy, and the starburst design of this mirror adds a touch of whimsy and creativity to the space Mirrors are known for their ability to make a room feel more spacious and airy, and the starburst design of this mirror adds a touch of whimsy and creativity to the space

Mirrors are known for their ability to make a room feel more spacious and airy, and the starburst design of this mirror adds a touch of whimsy and creativity to the space Mirrors are known for their ability to make a room feel more spacious and airy, and the starburst design of this mirror adds a touch of whimsy and creativity to the space

First, measure and mark the dimensions of the glass on the backside using a permanent marker First, measure and mark the dimensions of the glass on the backside using a permanent marker

First, measure and mark the dimensions of the glass on the backside using a permanent marker First, measure and mark the dimensions of the glass on the backside using a permanent marker

Comment area