- Top: 3332Step on: 96145

ladder reinforcement for cmu

People involved | Date:2025-08-14 03:29:32

Related articles

The versatility of portable welding ventilation systems is unmatched, offering manufacturers the ability to perform high-quality welding while ensuring that both workers and machinery remain protected. When combined with automated welding technology, these systems provide the ideal environment for sustained productivity and safety.

Xulosa

Conclusion

Portable Welding Techniques Revolutionizing the Welding Industry

- Filtration Efficiency Look for systems equipped with HEPA filters and activated carbon filters to ensure high filtration effectiveness, removing both particulate matter and toxic gases.

To ensure optimal performance, regular maintenance of the exhaust arm is crucial. This includes cleaning filters, inspecting duct connections, and checking for any damage or blockages. It is essential to replace filters according to the manufacturer's recommendations, as clogged filters can diminish airflow and reduce the system's efficiency.

Technology and Innovation

Преимущества использования портативного оборудования

- Filter Quality Look for fountains that use high-quality filters that can effectively remove impurities. Some brands even offer replacement filters that can help prolong the life of the fountain.

Welding is an essential process in various industries, serving as a critical technique for joining metals and creating robust structures. However, this crucial task comes with risks, particularly the exposure to hazardous fumes and gases emitted during the welding process. Welding fumes consist of a complex mixture of metallic oxides, silica, and other harmful components that can pose serious health threats to workers. To mitigate these risks, portable welding fume extraction systems have emerged as indispensable tools for enhancing workplace safety and ensuring compliance with health regulations.

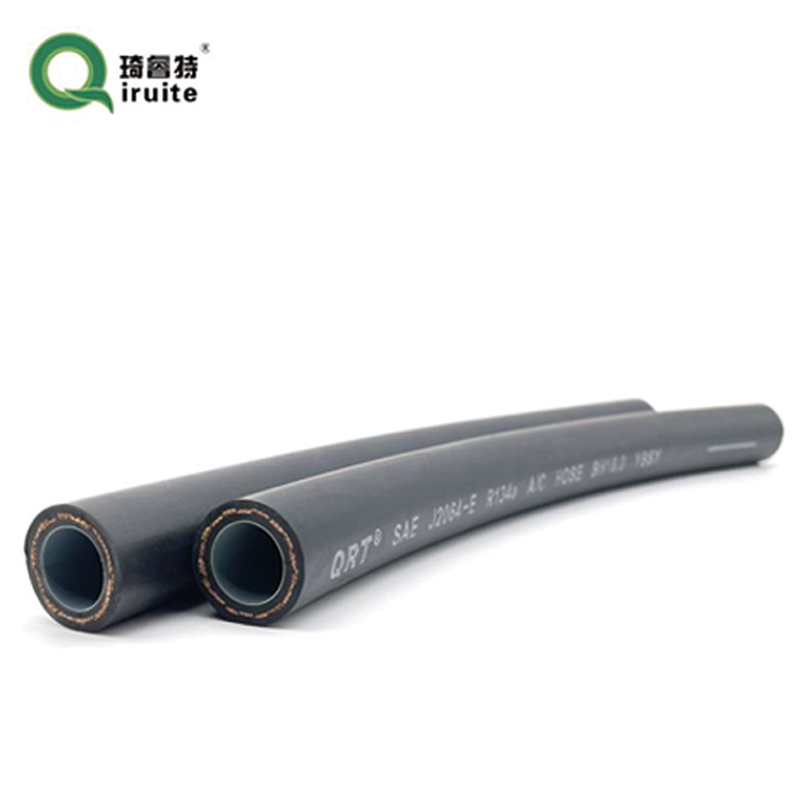

It requires careful handling and an understanding of the vehicle's intricate system It requires careful handling and an understanding of the vehicle's intricate system

It requires careful handling and an understanding of the vehicle's intricate system It requires careful handling and an understanding of the vehicle's intricate system Engineers carefully design the pathways to minimize energy loss and optimize the flow of hydraulic fluid Engineers carefully design the pathways to minimize energy loss and optimize the flow of hydraulic fluid

Engineers carefully design the pathways to minimize energy loss and optimize the flow of hydraulic fluid Engineers carefully design the pathways to minimize energy loss and optimize the flow of hydraulic fluid

Comment area