- Top: 38994Step on: 23

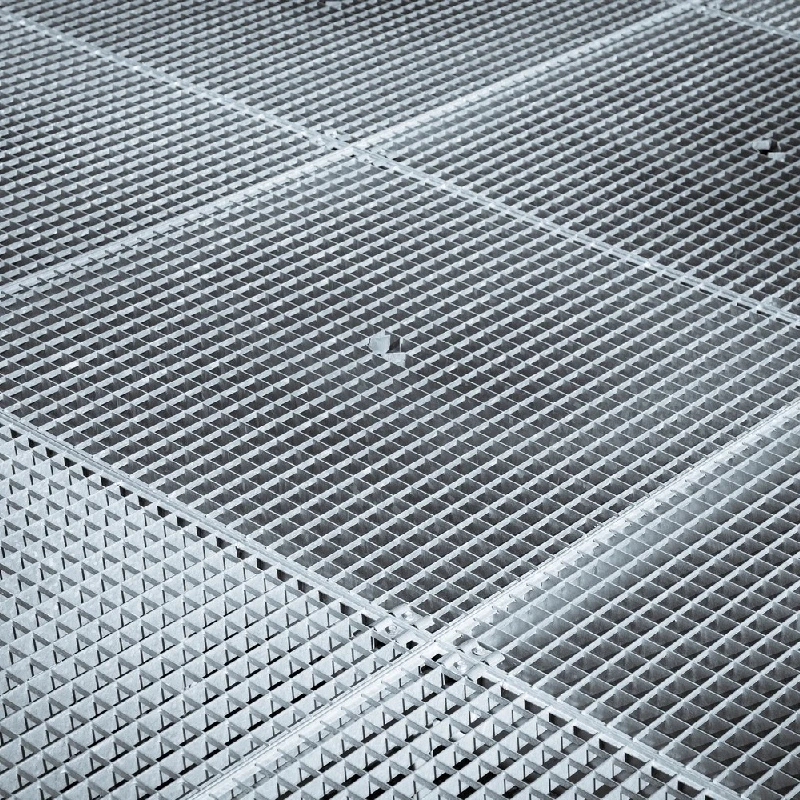

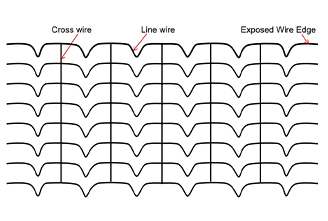

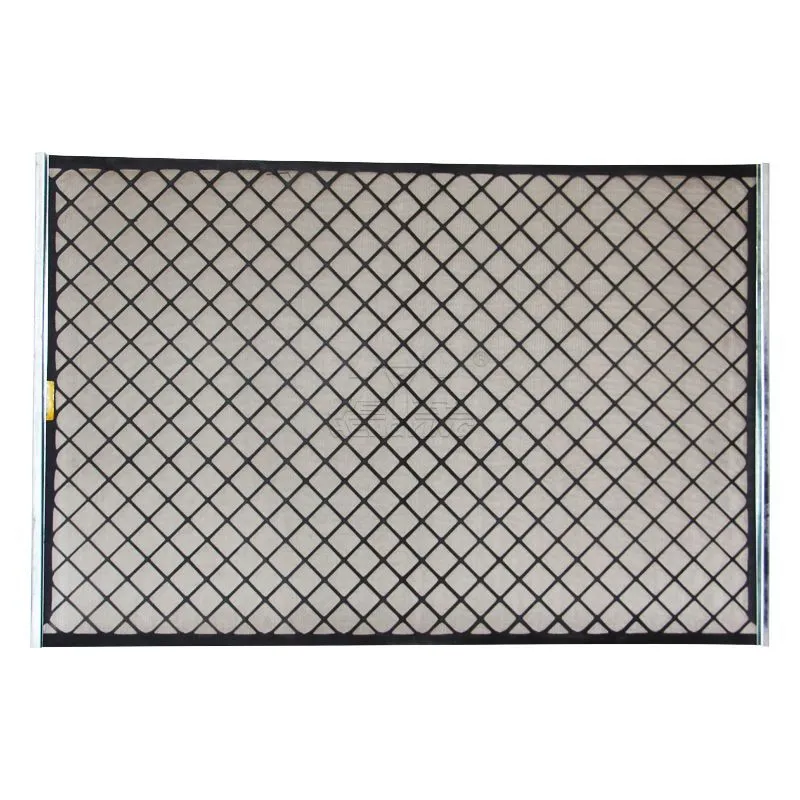

Shijiazhuang TangChao Metal bricktor reinforcement mesh

People involved | Date:2025-08-16 00:03:59

Related articles

Mitigation Strategies

There are several types of ventilation systems that can be employed in robotic welding environments

. Each system has its advantages and is suited to different application needs.As the logistics industry continues to evolve, the role of forklifts is also adapting. Innovations in technology, such as electric forklifts and automated guided vehicles (AGVs), are becoming more prevalent. Electric forklifts offer quieter operations and reduced carbon footprints, making them environmentally friendly alternatives to traditional fuel-powered models. AGVs, on the other hand, represent a step toward automation in warehouses, enabling streamlined operations with minimal human intervention.

En cuanto al futuro del sprayfärg automatizado, se prevé que seguirá avanzando con los desarrollos en la inteligencia artificial y la robótica. Las máquinas de pintura automatizadas están comenzando a incorporar tecnologías de aprendizaje automático, permitiéndoles adaptarse a diferentes superficies y tipos de pintura de manera más eficiente. Este desarrollo podría significar que, en un futuro cercano, incluso las pequeñas empresas puedan acceder a estas tecnologías, democratizando el uso de técnicas avanzadas de pintura.

The Importance of Ventilation in Welding

- 3. Testing and Refinement Implement rigorous testing protocols to assess performance, reliability, and safety, followed by refinements based on feedback.

Origins of the Hinang Boom Braso

- Improved Worker Safety By reducing the concentration of hazardous fumes, ventilation systems help protect the health of workers, minimizing the risk of occupational diseases.

Understanding Container Lifting Machine Prices

Comment area