- Top: 89678Step on: 11197

evaporative cooling roof

People involved | Date:2025-08-15 02:33:52

Related articles

Conclusion

In industries where heavy-duty welding is commonplace, such as automotive and construction, the need for effective fume extraction is even more critical. Industrial fume extractors are designed to handle the large quantities of smoke and fumes generated by welding. These extractors can efficiently remove hazardous air pollutants, preventing them from spreading across the workspace and potentially affecting workers' health.

Invest in a Healthier Work Environment Today!

2. Stainless Steel Rods Stainless steel rods are designed for welding stainless steel materials. They have added alloys that enhance their corrosion resistance and strength, making them suitable for applications in food processing, chemical industries, and architectural structures.

- Size and Capacity Consider the number of cats in your household and their drinking habits. A larger fountain may be beneficial for multiple cats, while a smaller model may be adequate for just one.

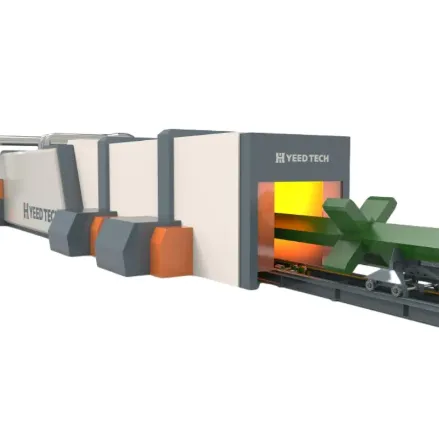

In an era where sustainability is a top priority, automatic spraying lines are paving the way for greener manufacturing practices. These systems are designed to optimize material usage, reducing waste and lowering environmental impact. For instance, the precision of automatic spray painting ensures that only the required amount of paint is applied, minimizing overspray and contamination.

In larger facilities, welding exhaust fans are essential for maintaining a clean and safe working environment. These fans help circulate air, removing welding fumes and smoke that might otherwise linger in the workspace.

3. Exhaust Fans These larger systems are designed to remove contaminated air from a designated area. They can be set up to draw fumes out of larger welding shops or confined spaces, helping to maintain a balanced air pressure and reduce the concentration of harmful substances.

Comment area