- Top: 765Step on: 1172

spreader zum heben von containern

People involved | Date:2025-08-14 06:57:55

Related articles

5. Space Efficiency Many models are designed to have a small footprint, making them suitable for use in tight spaces. This feature not only maximizes workspace utilization but also allows for maneuverability in congested areas.

- الأحداث والنشاطات في الفعاليات العامة أو الحفلات، يمكن استخدام هذا النظام لضمان ألا يؤثر التدخين على الحضور.

3. Precision Control Modern spray coating machines come equipped with advanced control systems that allow for meticulous adjustments to be made in terms of spray width, pressure, and distance from the surface. This precision is critical when dealing with delicate items or specific application requirements.

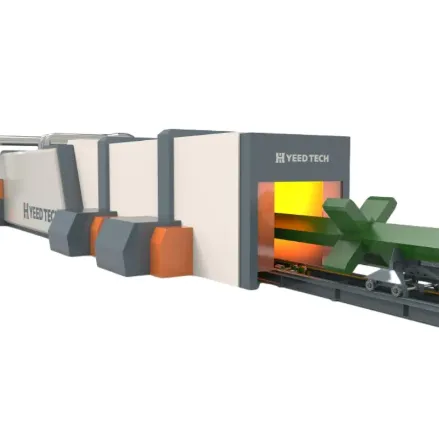

By incorporating steel structure processing equipment into the painting line, manufacturers can address the specific needs of large-scale projects. This integration enhances the durability of coatings, protects materials from corrosion, and ensures a flawless appearance.

- 4. Increasing Safety To mitigate health risks associated with prolonged exposure to paint and related chemicals by reducing human involvement in hazardous environments.

Importance of Efficient Container Loading

The Significance of Container Lifting Devices in Modern Logistics

- Installation Services Whether it’s installing HVAC systems in buildings or placing large appliances, the Górny Podnośnik allows technicians to work efficiently at height or in tight spaces without physical strain.

What is a Steel Floor System?

Moreover, authoritativeness in this domain is supported by a slew of successful case studies and field deployments. A notable example comes from the automotive industry, where automated spray systems have been integrated with robotic arms to coat car bodies. This synergy advances production lines, enabling them to operate 24/7 with minimal supervision while ensuring each vehicle receives the same high-quality finish.

automated spray coating systems

Comment area