In conclusion, fire-resistant drywall tape is an essential component in creating safer living and working environments. As regulations become stricter and the focus on safety grows, incorporating fire-resistant materials into building projects is no longer optional; it is imperative. By understanding the benefits and proper application of fire-resistant drywall tape, builders and homeowners alike can contribute to a safer infrastructure, ultimately protecting lives and property from the devastating effects of fire. Whether in residential homes, commercial spaces, or industrial buildings, the choice to use fire-resistant drywall tape is a choice for safety, durability, and peace of mind.

The Benefits and Importance of Butyl Weather Stripping

Market Trends and Availability

3. Automotive Repairs Car enthusiasts have also found this tape useful for temporary fixes, such as covering a damaged hose or sealing a leaking coolant reservoir, allowing for safe driving until proper repairs can be made.

1. High Temperature Resistance One of the primary advantages of self-fusing silicone tape is its ability to withstand extreme temperatures. It can operate effectively in a temperature range from -60°C to 260°C (-76°F to 500°F), making it suitable for high-heat applications.

Self-adhesive insulation tape is a remarkable product that has gained significant popularity across various industries and DIY projects. This versatile tape offers a myriad of applications, ranging from electrical insulation to home improvement, making it an essential item in both professional and personal toolkits.

Beyond color-coding, yellow electrical tape is often employed for insulation purposes. It is designed to withstand a certain degree of heat, moisture, and electrical current, making it ideal for insulating electrical connections. For example, when splicing wires together, applying yellow electrical tape around the connection point helps protect it from exposure to environmental elements, preventing moisture from seeping in and causing corrosion. Furthermore, this adds a layer of safety by ensuring that exposed wire does not come into contact with other conductive materials, which could otherwise lead to short circuits or electrical fires.

yellow tape electrical

Brand Reputation

insulation tape price

How do you properly tape a motor lead connection? What type of tape do you use for a connection, and how many layers? We see lots of motor connections in the field – lots of them. And it is shocking what we find at times. A properly insulated connection is both reliable and safe (funny how safety and reliability complement each other). But it is a topic that seems to be overlooked and taken for granted.

In addition to plumbing, heat tape is vital in agricultural applications. Farmers often use it to maintain soil temperature, ensuring seedlings and crops grow optimally in cooler climates. Furthermore, heat tape can be employed in greenhouses to prevent plants from freezing during cold spells, thus extending the growing season.

safety floor tape. In high-risk areas where special precautions are necessary, safety floor tape can be used to clearly mark off these areas and prevent unauthorized access.

DIY enthusiasts also find black PVC electrical tape invaluable. Whether it’s for crafting, organizing cords, or making quick repairs, this versatile tool is easily accessible and simple to use. For instance, if a power cord becomes frayed, wrapping it securely with black PVC tape can quickly restore functionality without the need for costly repairs or replacements.

Many technicians opt for tape that can stretch without losing original form. This is helpful in wrapping wires because technicians must often stretch the tape around the cable, which needs to then return to its original form to provide a tight wrap. Lack of elongation can result in broken tape and uncovered cables.

Water-activated adhesives are very popular for packing tape. When the adhesive is used on cardboard, the bond it creates is so strong that the tape cannot be removed without damaging the cardboard. As a result, it is the perfect tamper-evident packaging. No one can open a box sealed with water-activated tape without leaving obvious evidence. Water-based is the cheapest of all adhesives.

Additionally, butyl rubber is a preferred material for environmentally conscious companies. Its production process typically has a lower environmental impact compared to natural rubber, as it does not rely on extensive agricultural practices. Furthermore, the durability and longevity of butyl rubber rolls contribute to sustainability, reducing waste over time.

Regular maintenance of the door bottom seal rubber strip is important to ensure its effectiveness and longevity. Clean the strip regularly to remove dirt and debris that can interfere with its sealing ability. Replace the strip if it becomes damaged or worn out to maintain a tight seal and optimal insulation.

(3) The service life is up to 2000 hours at 260 ℃.

- Latest articles

-

Thickness

- Repairing damaged insulation: Can be used to quickly patch and repair damaged insulation on electrical wires.

- Tape for marking floors is an essential tool in many industries and businesses. Whether it's creating boundaries for safety purposes, marking off designated areas, or directing traffic flow, floor marking tape plays a crucial role in maintaining organization and order in a workspace.

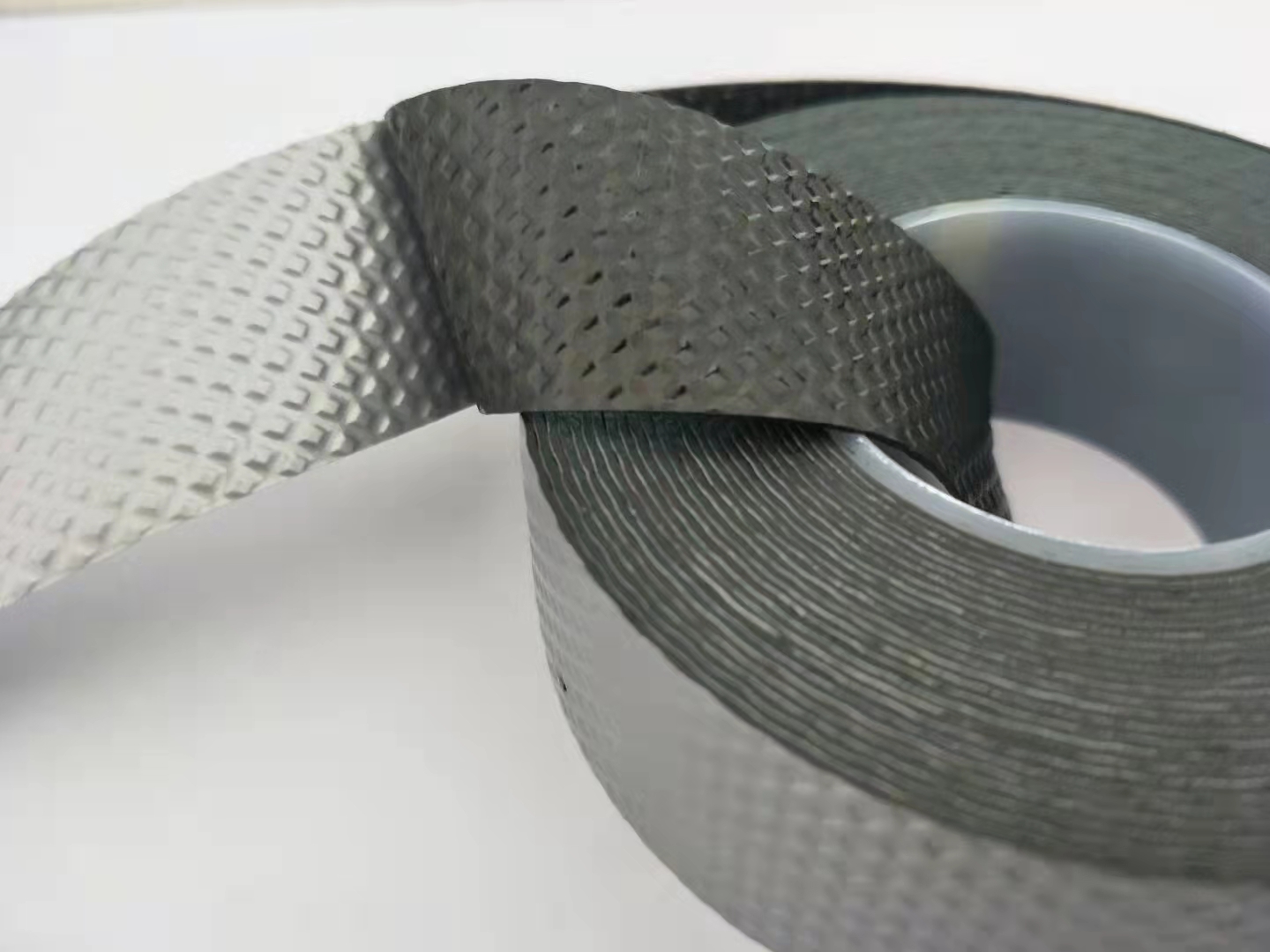

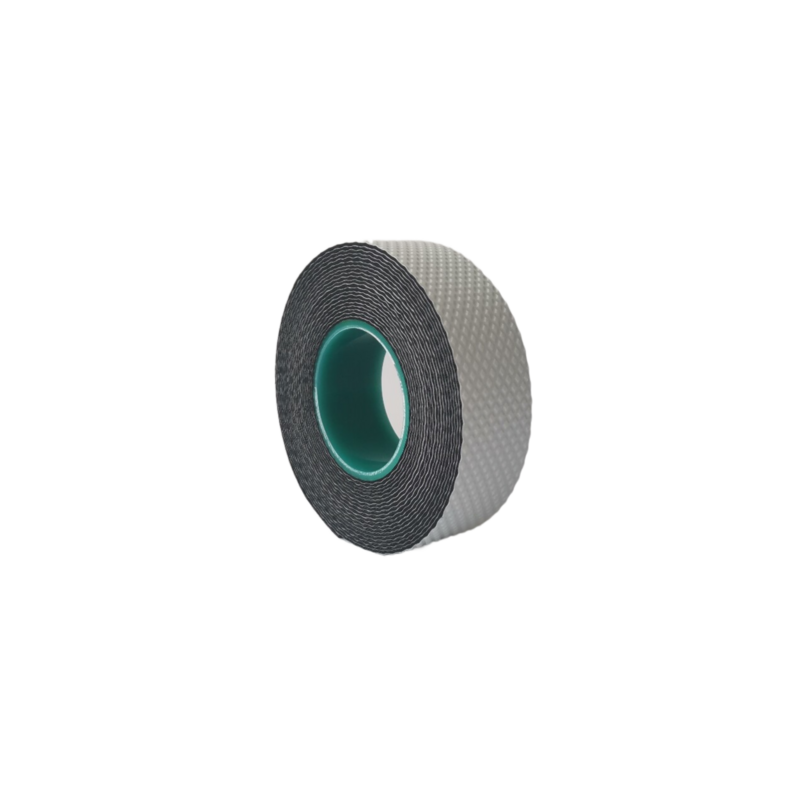

- It is a non-tacky silicone-rubber tape that is used for adhesion or protection of materials. Rubber tapes are used in many areas like providing protection and electrical insulation layer for different equipment like cables and electrical joints. Rubber tape is resistant to heat, weather and sunlight. In solar module manufacturing, it is widely used as a sealant due to its mainly good mechanical properties, impact resistance, high adhesion properties, and relatively cheap cost. It is used during manufacturing, installation and normal operation of PV modules for mounting, adhesion and sealing requirements for modules. Advantages and disadvantages of using rubber tape edge sealant Rubber sealing tape meets the demand of a wide variety of difficult sealing applications. It can be used for oversealing of an existing joint or penetration, normal sealing applications which are typically done with a gasket, or liquid sealant/adhesive. The rubber sealant tape is flexible, durable, and abrasion resistant. It is also conformable which helps create an effective seal over contours, edges rivets, and edges. Rubber tape also has good moisture resistance and as an edge sealant primarily prevents moisture ingress and protects components besides insulation splices and connections in electrical components. The rubber tape is susceptible to cuts and abrasion as it has low tear resistance. This disadvantage is increased because the rubber tape is wrapped while stretched, and stays under internal tension. Yet, these same properties, make tape removal when needed clean and easy.

As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems

As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems

Comment area