- Top: 32Step on: 96

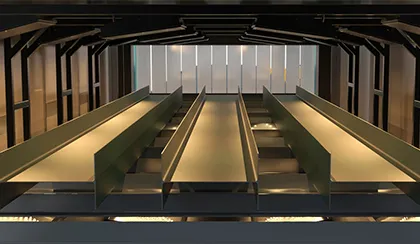

sistem penapisan kimpalan

People involved | Date:2025-08-14 06:29:53

Related articles

The integration of steel structure manufacturing equipment with automatic spray painting systems has transformed how manufacturers handle large-scale production. These machines provide consistent and even coatings, ensuring that every piece meets stringent quality standards.

Moreover, many automatic paint spray machines are equipped with recovery systems that recycle unused paint, further enhancing their eco-friendliness. These machines also reduce emissions of volatile organic compounds (VOCs), helping companies meet stringent environmental regulations while maintaining their commitment to sustainability.

Advantages of Implementing Robotic Welding Arms

1. Precision and Consistency One of the standout features of robotic welding arms is their ability to perform tasks with a level of precision unattainable by human welders. The robotic systems can execute complex welding patterns uniformly, reducing the likelihood of defects and ensuring consistent quality across multiple pieces.

5. Space Efficiency Many models are designed to have a small footprint, making them suitable for use in tight spaces. This feature not only maximizes workspace utilization but also allows for maneuverability in congested areas.

The Role of Mobile Welding Fume Extractors in Modern Welding

كيفية عمل النظام

Moreover, maintaining a clean working environment improves visibility and safety. Inadequate ventilation can lead to the accumulation of smoke, making it difficult for welders to see their work and increasing the likelihood of accidents. By integrating exhaust arms into welding setups, companies can create a safer and more efficient workspace.

The Steel Floor System An Overview

Comment area