- Top: 218Step on: 4

Hebei Chida 887 4.75 gal tropi-cool white roof coating

People involved | Date:2025-08-16 02:58:20

Related articles

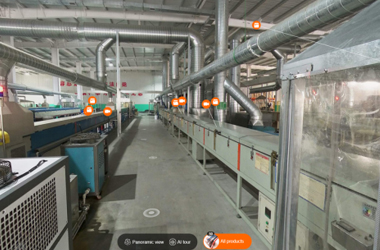

Automated spray coating systems integrate cutting-edge technology with sophisticated engineering to deliver consistent and uniform coating applications across a variety of surfaces. Their precision is unmatched, thanks to advanced robotics and control systems that ensure each component receives the correct amount of coating material, reducing waste and ensuring uniformity and accuracy. This precision significantly reduces the need for rework and material consumption, resulting in substantial cost savings for manufacturers.

Why Choose Yeed Tech Co., Ltd. for Your Welding Fume Extraction Needs?

Welding fume and dust collectors are engineered to capture airborne contaminants. These systems typically utilize a combination of filtration and airflow management techniques.

Trustworthiness is paramount when integrating automated systems into critical operational facets. Manufacturers must rely on systems that have been rigorously tested under various operational conditions. Reputable suppliers provide extensive documentation, from compliance with international standards to validation reports demonstrating reliability and durability. Case studies often accompany these documents, showcasing the systems' successful deployment in similar industrial settings.

Partner with Leading Container Handling Equipment Manufacturers

2. Filtration Units These systems involve filters that capture harmful particles from the air before returning it to the workspace. Mobile or stationary filtration units can be placed near the welding operation, providing flexibility and ease of use.

- Service Conditions The environment in which the welded structure will operate (e.g., exposure to chemicals, heat, or moisture) can influence the type of welding rod to choose for maximum durability and longevity.

Understanding the Importance of Hydration

Comment area