- Top: 28924Step on: 17

evap cooler roof jack

People involved | Date:2025-08-14 13:32:48

Related articles

The demand for automatic spray coating machines has surged as industries seek to improve product consistency while reducing labor costs and waste. These machines offer cutting-edge technology that applies coatings evenly across diverse surfaces and materials. This ensures not only aesthetic appeal but also functional durability, crucial for products subjected to environmental stressors like moisture, temperature changes, and mechanical abrasion.

In today's fast-paced logistics industry, flexibility is essential. That’s why Yeed Tech Co., Ltd. offers a portable shipping container lift that allows you to easily move lifting capabilities wherever they're needed. Lightweight yet sturdy, this portable solution is perfect for on-the-go operations, enabling you to tackle container handling tasks wherever they arise.

- Construction In construction, transporting heavy materials like steel beams, concrete blocks, and large tools is essential. The Górny Podnośnik plays a critical role in moving these items safely and efficiently.

Efficiency is a critical factor in modern production lines, and automatic paint spraying robots play a pivotal role in optimizing operations. These robots can operate continuously, significantly reducing downtime and boosting productivity.

Straddle carriers provide a unique solution for container handling, especially in intermodal operations. These vehicles can straddle over containers, allowing them to lift and transport them with ease. Their ability to navigate tight spaces while transporting heavy loads makes them invaluable in busy ports where maximizing space is crucial.

Otra área en la que el sprayfärg automatizado está ganando terreno es en el arte y el diseño. Artistas y diseñadores han comenzado a incorporar esta tecnología en sus obras, permitiéndoles crear murales complejos y personalizaciones en productos de manera más eficiente. Gracias a la automatización, se pueden lograr patrones intricados y detalles finos que, de otro modo, requerirían muchas horas de trabajo manual.

In modern manufacturing, precision and efficiency are paramount, and automated welding arms have revolutionized the way industries approach welding. These robotic arms ensure that every weld is perfect, reducing the chances of defects while increasing productivity. By using advanced technology, automated welding arms can handle a variety of materials, providing consistent, high-quality results for both simple and complex welding tasks. This innovation not only saves time but also improves safety and minimizes the need for manual labor.

- 2. Weight Capacity The markings often include information about the maximum load capacity of the container. This helps operators understand how much weight can be safely lifted and transported, reducing the risk of accidents during handling.

There are several types of svetsventilationsutrustning available, each designed to suit different welding environments and needs

How Welding Fume and Dust Collectors Work

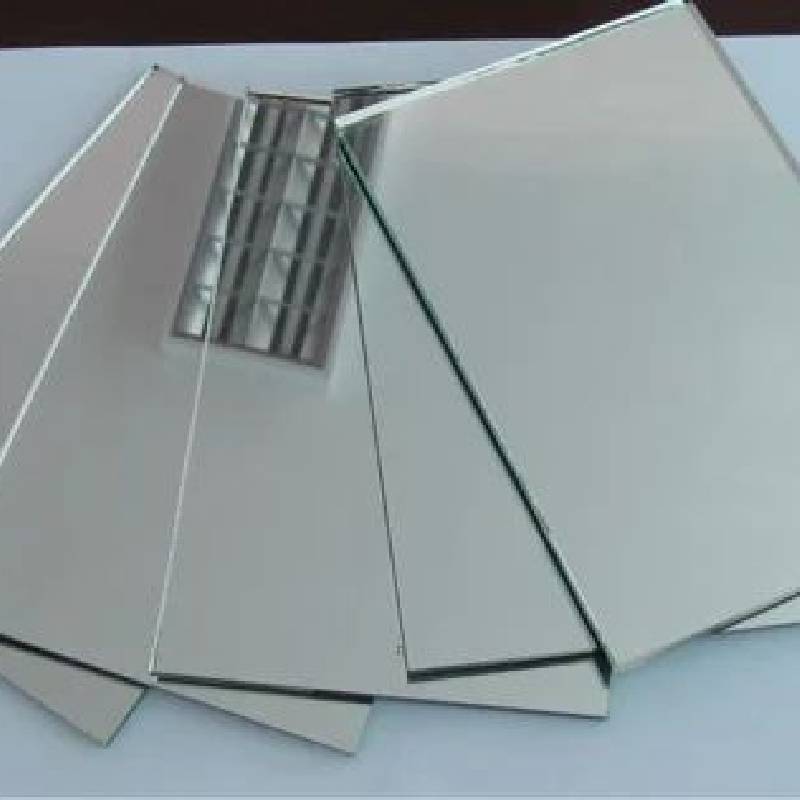

They are also used in solar panels and other technologies to enhance the efficiency of light absorption and reflection They are also used in solar panels and other technologies to enhance the efficiency of light absorption and reflection

They are also used in solar panels and other technologies to enhance the efficiency of light absorption and reflection They are also used in solar panels and other technologies to enhance the efficiency of light absorption and reflection

Comment area