- Top: 61498Step on: 2

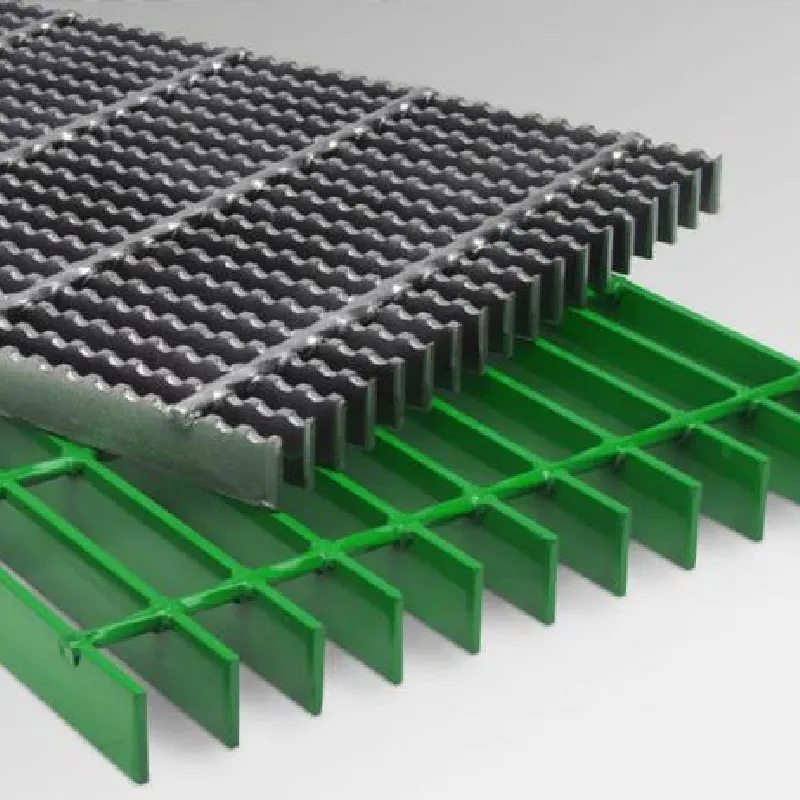

galvanised mesh

People involved | Date:2025-08-15 00:21:33

Related articles

Nevertheless, what sets automatic paint spraying equipment apart is not solely its technical superiority but the tangible enhancements it brings to operational workflows. Real-world experiences further reinforce its merits. Companies making the shift report substantial savings in both labor and material costs, alongside notable improvements in product turnaround times. This investment not only aligns with modern efficiency targets but also yields significant competitive advantages, translating into better profit margins and market positioning.

In conclusion, portable fume collectors represent a significant advancement in workplace safety and air quality management. They not only protect workers from harmful pollutants but also promote a healthier and more productive work environment. As industries continue to evolve and place greater emphasis on worker safety and environmental responsibility, investing in effective solutions like portable fume collectors will become increasingly important. Ensuring a clean and safe workspace is not just an ethical responsibility but also a critical investment in the health and efficiency of the workforce.

- Air Spray Utilizing compressed air to atomize the coating material, this method is highly versatile but can be less efficient in terms of paint usage.

The integration of automatic spray painting machines into manufacturing processes represents a significant step toward the future of industrial production. These machines combine speed, precision, and quality, making them a valuable investment for businesses seeking to optimize their operations.

Modern wall-mounted welding fans often feature variable speed settings, allowing operators to adjust the airflow based on the intensity of welding operations

. Some models are fitted with filters to capture particulates and improve air quality.In residential applications, automatic paint dispensers are cherished for their convenience. Homeowners undertaking DIY projects find them particularly useful, as they eliminate the daunting task of mixing paints by hand. Their simplicity ensures users can match colors precisely to pre-defined templates or bespoke palettes, achieving an aesthetically pleasing finish without professional intervention.

A wall-mounted welding exhaust fan is a ventilation device specifically designed to remove contaminated air from welding areas. These fans are typically installed in a wall or window and are strategically positioned to capture harmful fumes and gases generated during welding operations. Most wall-mounted fans are equipped with high-capacity motors and durable construction to withstand the harsh conditions of welding environments.

Comment area