- Top: 777Step on: 1946

containerlyftmaskin

People involved | Date:2025-08-14 03:51:33

Related articles

As industries continue to prioritize efficiency and precision in production processes, the implementation of automated systems is becoming increasingly essential. One such innovation is the automatic paint spraying equipment, which streamlines painting applications, enhances quality, and reduces labor costs. This project proposal outlines the development and implementation of an advanced automatic paint spraying system tailored for various industrial needs.

Applications Across Industries

1. Strength and Durability Steel is known for its impressive strength-to-weight ratio. This means that buildings constructed with steel floor systems can support heavy loads while requiring less material overall. This strength ensures longevity and reduces the likelihood of structural failures over time.

Unit of Smoke Extraction An Essential Component for Indoor Air Quality

4. Technology and Features Modern container lifting machines come equipped with advanced technology such as telematics, automation, and safety features, which can increase the cost. Features like load monitoring systems, anti-collision devices, and ergonomically designed controls enhance operational efficiency and safety but add to the initial investment.

Worker safety is another significant benefit of adopting automatic paint sprayers. Manual painting processes often expose workers to harmful chemicals and fumes, increasing the risk of health issues. By automating these tasks, businesses can protect their workforce while maintaining productivity.

Exploring the Importance of Exhaust Systems in Modern Vehicles

Understanding Welding Fume and Dust Collectors Essential Equipment for Industrial Safety

- Extended Equipment Lifespan Maintaining good air quality can also prolong the life of welding equipment and fixtures, as they are less likely to be affected by the corrosive effects of welding fumes.

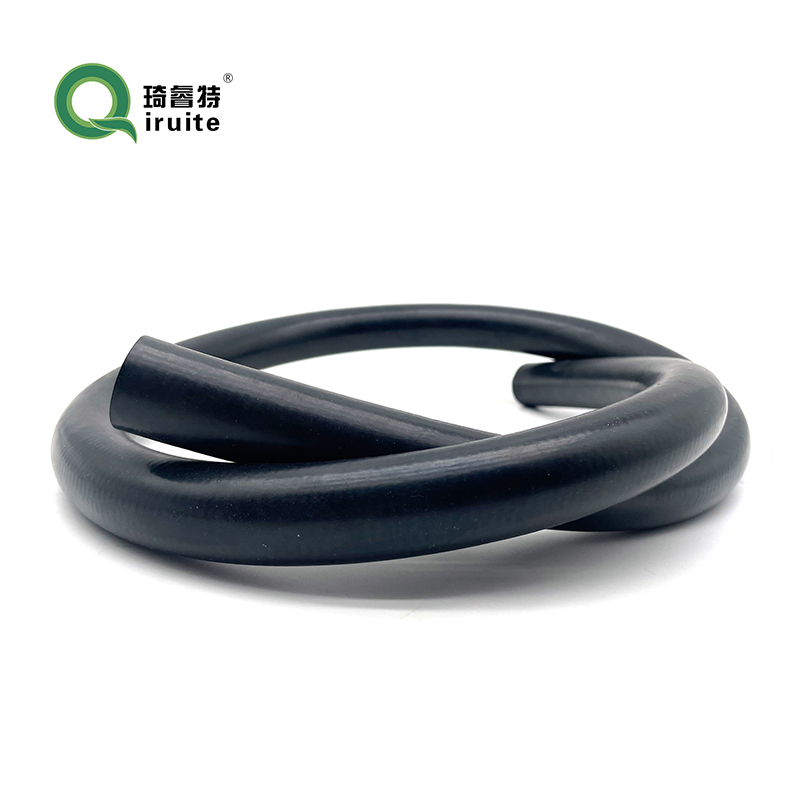

They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer

They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer This can result in increased steering effort, making it harder to maneuver your Odyssey, particularly at low speeds This can result in increased steering effort, making it harder to maneuver your Odyssey, particularly at low speeds

This can result in increased steering effort, making it harder to maneuver your Odyssey, particularly at low speeds This can result in increased steering effort, making it harder to maneuver your Odyssey, particularly at low speeds

Comment area