- Top: 24239Step on: 3

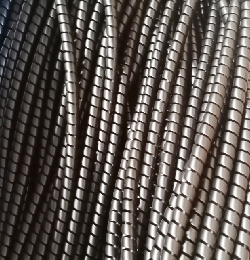

buy chicken fencing

People involved | Date:2025-08-14 15:22:35

Related articles

Ultimately, the decision to employ an automatic spray painting machine is one that underscores a commitment to quality, efficiency, and forward-thinking production strategies. Not only does it signify an alignment with cutting-edge technology, but it also positions your business as a leader in delivering products that meet high standards in craftsmanship and environmental consideration.

In larger facilities, welding exhaust fans are essential for maintaining a clean and safe working environment. These fans help circulate air, removing welding fumes and smoke that might otherwise linger in the workspace.

Incorporating automatic paint spraying equipment into your operations not only elevates the quality of your finished products but also enhances overall production efficiency. However, it is essential to approach this integration with a comprehensive strategy that includes proper training for personnel and regular maintenance schedules to keep the equipment functioning at optimal levels. By fostering a culture of continuous improvement and adaptation to new technologies, businesses can ensure they leverage the full spectrum of advantages offered by automatic spraying systems, thus maintaining a competitive edge in an increasingly automated world.

- Filter Quality Look for fountains that use high-quality filters that can effectively remove impurities. Some brands even offer replacement filters that can help prolong the life of the fountain.

Understanding Spray Coating Equipment

Conclusion

Welding processes generate a significant amount of fumes and gases that can be hazardous to the health of workers. Fumes produced during welding can contain harmful substances such as metal oxides, silicates, and other volatile organic compounds. Continuous exposure to these pollutants can lead to serious health issues, including respiratory problems, skin irritations, and long-term diseases such as lung cancer.

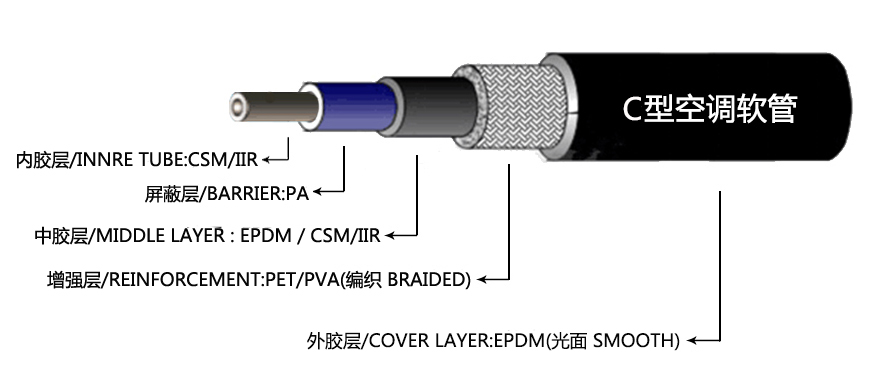

If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment

If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment It mandates extensive testing and validation procedures, both simulated and real-world, to minimize risks and ensure that these autonomous systems can respond effectively to unforeseen situations It mandates extensive testing and validation procedures, both simulated and real-world, to minimize risks and ensure that these autonomous systems can respond effectively to unforeseen situations

It mandates extensive testing and validation procedures, both simulated and real-world, to minimize risks and ensure that these autonomous systems can respond effectively to unforeseen situations It mandates extensive testing and validation procedures, both simulated and real-world, to minimize risks and ensure that these autonomous systems can respond effectively to unforeseen situations

Without properly functioning brake lines, the force generated by the driver's foot would not reach the brakes, rendering them useless Without properly functioning brake lines, the force generated by the driver's foot would not reach the brakes, rendering them useless

Without properly functioning brake lines, the force generated by the driver's foot would not reach the brakes, rendering them useless Without properly functioning brake lines, the force generated by the driver's foot would not reach the brakes, rendering them useless Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety

Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety Any leakage or damage to the hose can lead to reduced power steering assistance, making the vehicle harder to steer and potentially impacting overall driving safety Drain the remaining fluid from the system into the drip pan Drain the remaining fluid from the system into the drip pan

Drain the remaining fluid from the system into the drip pan Drain the remaining fluid from the system into the drip pan This process often requires the use of specialized tools such as wrenches and sealants to prevent leaks This process often requires the use of specialized tools such as wrenches and sealants to prevent leaks

This process often requires the use of specialized tools such as wrenches and sealants to prevent leaks This process often requires the use of specialized tools such as wrenches and sealants to prevent leaks

Comment area