- Top: 8118Step on: 712

system odciągu dymów spawalniczych

People involved | Date:2025-08-14 05:04:58

Related articles

Energy Efficiency

Ultimately, adopting an automatic paint dispenser can significantly elevate the quality of painting tasks—whether you're a DIY enthusiast or a seasoned professional. Their cutting-edge features and dependable performance empower users to undertake projects with newfound confidence and precision. By enabling seamless color mixing and reducing material waste, these devices not only optimize painting processes but also contribute to more sustainable practices in the painting industry.

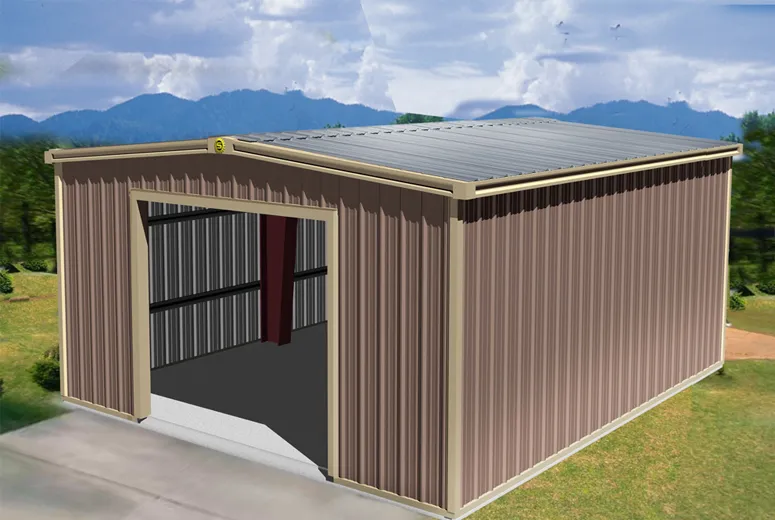

2. Speed of Construction Steel components are often prefabricated, allowing for faster assembly on-site. The use of steel systems can significantly reduce construction time, enabling projects to be completed ahead of schedule, which is particularly advantageous in commercial and industrial applications.

Real-world experience further underscores the benefits of automated spray coating systems. Consider the experience of a medium-sized electronics manufacturer that incorporated automated spray coating into its production line. The transition resulted in a 30% increase in production speed and a significant reduction in material waste. Additionally, the consistency of the coating improved noticeably, reducing the defect rate by half and exponentially enhancing the final product's marketability.

For those considering the transition to automated systems, understanding the initial investment versus long-term gains is essential. While the upfront cost may appear daunting, the return on investment is realized through improved throughput, lower labor costs, and reduced material waste. Consulting with experienced professionals during the planning and implementation phase is crucial, as they can provide insights tailored to specific industry needs and operational scales.

Additionally, our skilled team is always on hand to provide expert advice and support. From selecting the right equipment to ongoing maintenance, we are dedicated to aiding your business's growth and operational efficiency.

Streamlining Production with Automatic Spray Painting Machine Projects

Integration of such systems requires a strategic approach

. It involves a thorough analysis of existing production lines, a clear understanding of desired outcomes, and careful planning to minimize disruption. Companies that have successfully transitioned to automated spray coating systems often report significant improvements in quality assurance processes, facilitating smoother operations and enhancing customer satisfaction.Incorporating technologies like welding arms, portable welding fume extractors, and welding ventilation systems is essential for creating a more sustainable manufacturing environment. These tools not only enhance operational efficiency but also address critical health and environmental concerns. By adopting solutions such as smoke eaters for welding and welding fume extraction systems, manufacturers can reduce their carbon footprint while maintaining high-quality production standards. As industries continue to prioritize sustainability, these advanced welding technologies will remain at the forefront, paving the way for greener and more responsible manufacturing practices.

Comment area