- Top: 14Step on: 64

cool roof coatings in coimbatore

People involved | Date:2025-08-15 02:14:30

Related articles

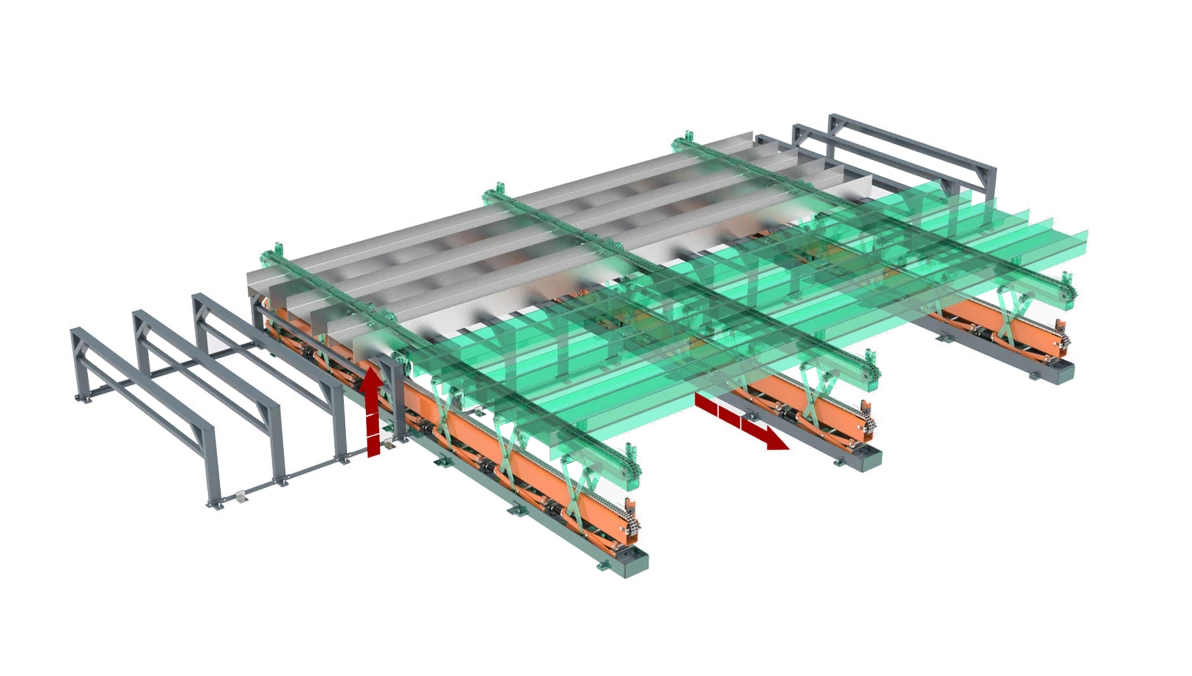

Automated spray coating systems integrate cutting-edge technology with sophisticated engineering to deliver consistent and uniform coating applications across a variety of surfaces. Their precision is unmatched, thanks to advanced robotics and control systems that ensure each component receives the correct amount of coating material, reducing waste and ensuring uniformity and accuracy. This precision significantly reduces the need for rework and material consumption, resulting in substantial cost savings for manufacturers.

Understanding Container Handlers

In the realm of manufacturing and industrial processes, the application of coatings plays a crucial role in enhancing the durability, appearance, and performance of products. Spray coating technology has revolutionized how coatings are applied in various industries, from automotive to aerospace to consumer goods. With the increasing demand for high-quality finishing solutions, selecting the right spray coating equipment manufacturer has become paramount for businesses looking to optimize their operations.

فوائد استخدام النظام

In today's rapidly evolving logistics and shipping industry, container lifting machines play a crucial role in ensuring efficient cargo handling. These machines, which include cranes, forklifts, and container handling equipment, are essential for moving shipping containers safely and swiftly. One of the foremost considerations when investing in such machinery is the price. Understanding the factors that influence the cost of container lifting machines can help businesses make informed purchasing decisions.

Welding fume collectors are advanced filtration systems designed to capture and remove toxic airborne particles produced during the welding process. These fumes, which contain a variety of hazardous metals such as chromium, nickel, and manganese, can pose long-term health risks to welders if not properly controlled. The fume collectors work by drawing in the contaminated air using powerful fans and filtering it through a series of high-efficiency filters, trapping the harmful particles before they can be inhaled by workers.

Maintenance of these fans is also uncomplicated. Regular dusting and occasional cleaning of the fan blades ensure optimal performance. Many models are equipped with removable filters that can be washed or replaced as needed, ensuring that the air being circulated is as fresh as possible. This ease of maintenance contributes to the longevity and efficiency of the exhaust fan, making it a worthwhile investment for any household.

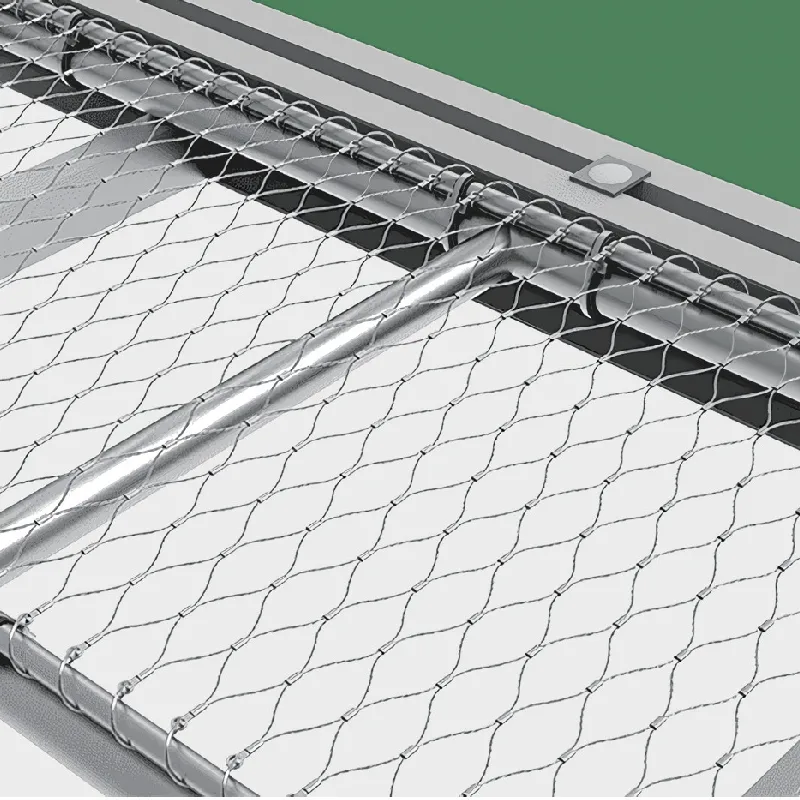

- Wall-Mounted Collectors These fixed units are ideal for workshops with dedicated welding stations. They capture fumes from fixed workstations and are often more powerful than portable units.

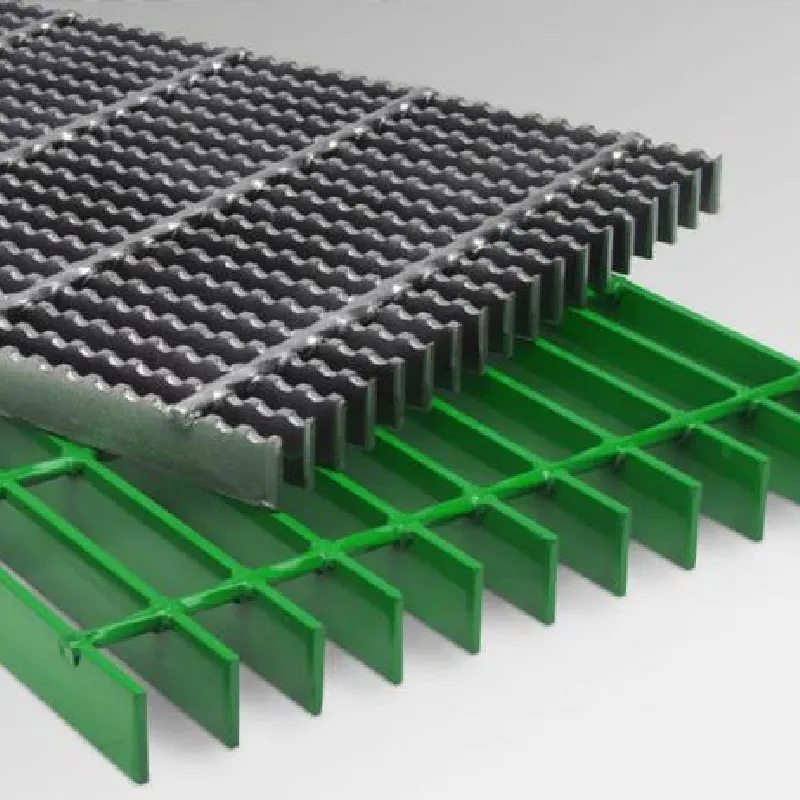

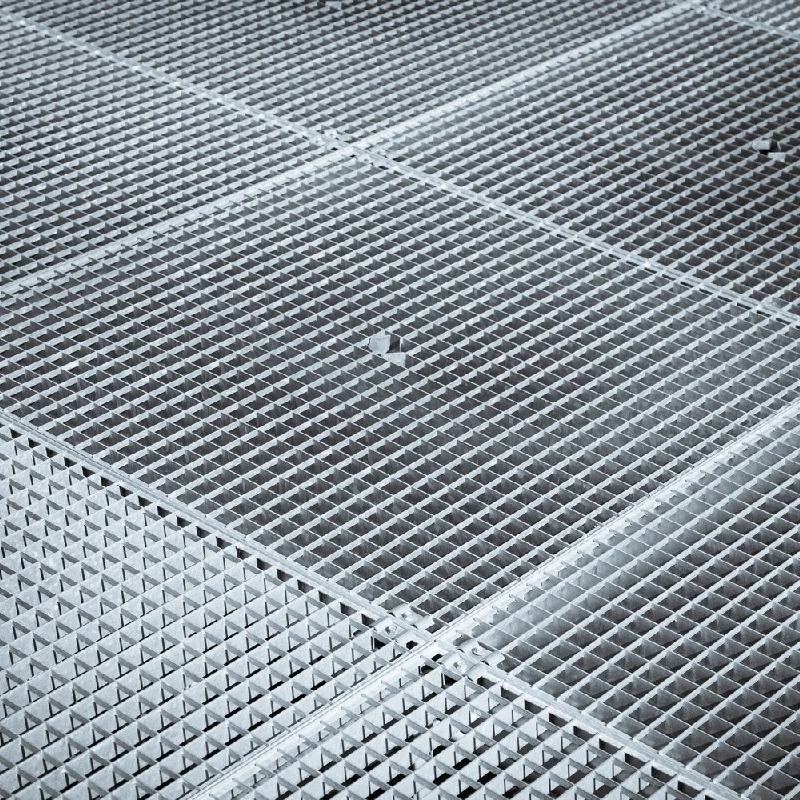

- Bridges Given their strength and durability, steel floor systems are extensively used in bridge construction, supporting heavy vehicle traffic and ensuring longevity.

Next, consider the required airflow and filtration efficiency. A device with higher air changes per hour will effectively capture more pollutants. Additionally, the type of filters used (e.g., HEPA, carbon, etc.) will impact the device's efficiency and the necessity for regular maintenance.

Comment area