- Top: 2932Step on: 9

4 x 4 field fence

People involved | Date:2025-08-14 08:06:39

Related articles

The flexibility of automatic paint sprayer machines extends to their ability to handle diverse projects, from small-scale prototypes to high-volume production runs. This adaptability ensures that businesses can remain competitive in an ever-changing market by meeting customer demands with efficiency and accuracy.

Welding fumes are a complex mixture of metallic oxides, silicates, and other materials that result from the welding process. These fumes can contain harmful substances such as manganese, zinc, and lead, which can lead to serious health issues if inhaled over prolonged periods. Chronic exposure can result in symptoms ranging from headaches, dizziness, and pulmonary issues to more severe chronic diseases, including neurological damage.

Factors Influencing the Choice of Welding Rod

The Role of Portable Welding Fume Extraction Systems

Automatic paint spraying equipment represents a paradigm shift from traditional manual methods, bringing precision and uniformity to the forefront of painting processes. Among the distinguishing features of top-tier systems is their ability to deliver consistent paint application, ensuring that every inch of a surface receives the same amount of paint. This level of precision not only improves the aesthetic finish but also enhances the durability and longevity of the coating, crucial for industries such as automotive and aerospace where quality standards are non-negotiable.

Saldırış Gazlarini Yo'qotish Tizimlarining Ahamiyati

While automated welding arms offer precision and speed, the efficiency of the welding process can be further enhanced with the use of proper fume extraction equipment. Welding fume filters and smoke collectors are essential in maintaining a clean environment, but they also contribute to the overall efficiency of the operation. By ensuring that fumes are quickly extracted from the workspace, these systems prevent the accumulation of particles that could interfere with the quality of the weld or disrupt the operations.

2. Space Optimization Properly designed containers can maximize storage space and make stacking easier, allowing for better use of warehouse resources.

1. Regular Maintenance Ensure that fume extraction systems are regularly inspected and maintained to operate at peak efficiency. This includes cleaning filters, checking for blockages, and ensuring that fans and motors are functioning correctly.

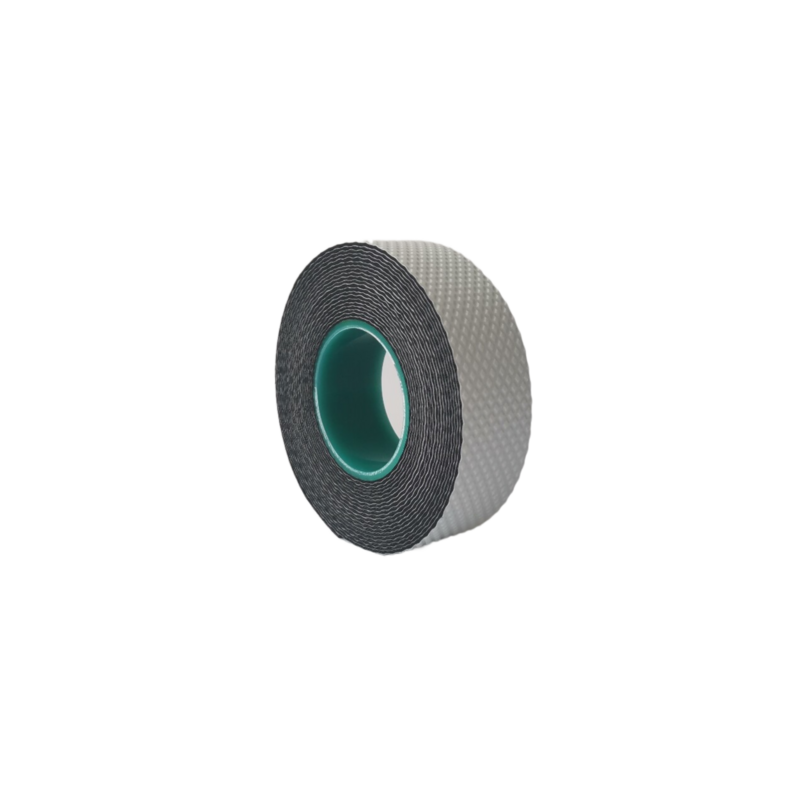

Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed

Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed

Comment area