- Top: 7229Step on: 91196

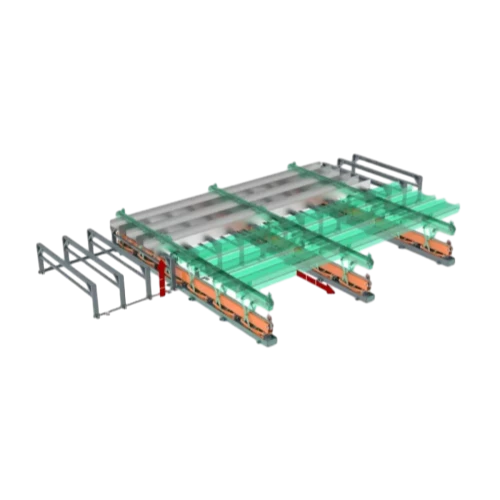

containerladeförderer

People involved | Date:2025-08-14 16:30:29

Related articles

Steel floor systems are now integral to various types of construction projects. They are commonly employed in the following applications

Boosting Efficiency with Automatic Paint Spraying Equipment

- Manufacturing Used for transporting raw materials and finished products within production facilities.

1. Flexibility and Mobility One of the standout features of portable welding fume extraction systems is their mobility. Welders often work in unpredictable environments where fixed extraction systems may not be feasible. Portable units can be easily moved close to the welding operation, ensuring that fumes are captured at the source, significantly reducing inhalation risks.

Investing in portable ventilation systems for welding is not just a matter of compliance with safety regulations; it's essential for promoting a healthy workplace. With a variety of options available, businesses can choose the right systems tailored to their specific needs. By ensuring that welders have access to safe, breathable air, companies not only protect their workforce but also enhance productivity and create a positive working environment. In the long run, the benefits of portable ventilation systems far outweigh the costs, making them a smart investment for any welding operation.

As the construction industry faces increasing scrutiny over its environmental impact, the use of tower steel has also evolved to become more sustainable. Steel is one of the most recycled materials globally, with a recycling rate of around 90%. This makes it an excellent choice for environmentally conscious builders. By repurposing scrap steel, construction companies can significantly reduce their carbon footprint while also cutting down on production costs.

The Steel Floor System An Overview

2. Space Optimization Properly designed containers can maximize storage space and make stacking easier, allowing for better use of warehouse resources.

Comment area