- Top: 41546Step on: 5

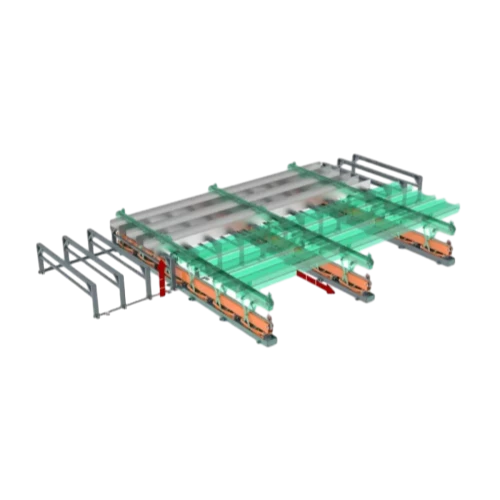

wysięgnik spawalniczy

People involved | Date:2025-08-14 04:32:56

Related articles

2. Space Optimization Properly designed containers can maximize storage space and make stacking easier, allowing for better use of warehouse resources.

- .

Efficiency is a critical factor in modern production lines, and automatic paint spraying robots play a pivotal role in optimizing operations. These robots can operate continuously, significantly reducing downtime and boosting productivity.

Furthermore, the environmental impact of welding has spurred the development of more sustainable practices. Portable welding technology now includes energy-efficient machines that consume less power while maintaining high output, alongside methods that generate lower emissions. This not only promotes a safer workplace but also aligns with global efforts towards sustainability in manufacturing and construction.

In conclusion, the steel floor system is a cornerstone of contemporary construction, offering a blend of strength, durability, and design flexibility. As urbanization accelerates and the demand for efficient, sustainable building practices grows, the role of steel floor systems will only expand. The ongoing innovations in this sector promise a future where steel not only supports our buildings but also contributes to a more sustainable and efficient construction industry.

When selecting a portable welding fume extraction system, several factors should be considered

What is an Exhaust Arm?

Additionally, infrastructure inadequacies in some regions can hinder the efficient operation of container trucks. Roads may be poorly maintained or congested, slowing down transportation and increasing costs. Addressing these challenges requires collaboration between governments, private companies, and logistics providers to enhance infrastructure and streamline processes.

What is a Robotic Welding Arm?

Comment area