- Top: 2169Step on: 1

proceso de pintura automatizado

People involved | Date:2025-08-14 06:42:54

Related articles

How Do They Work?

- Conduct Risk Assessments Regularly assess workplaces to identify risk areas where welding occurs. This assessment will help determine the necessary type and location of ventilation systems.

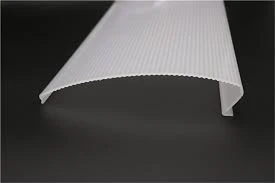

Several types of spray coating methods are commonly used

When metals are fused together through welding, high temperatures vaporize the metal, generating fumes that are often hazardous to human health. Common materials involved in welding, such as mild steel, stainless steel, and aluminum, release various toxic substances, including manganese, lead, and chromium. Prolonged exposure to these fumes can result in conditions such as “metal fume fever,” chronic bronchitis, reduced lung function, and even more severe illnesses like cancer.

Steel structure painting is essential for maintaining the integrity and aesthetic appeal of buildings, bridges, and other infrastructure. As cities and industries continue to grow, the demand for reliable, sustainable solutions for steel protection will remain high, ensuring that painted steel structures stand the test of time.

Container handlers play a crucial role in the overall supply chain operation. By facilitating the swift transfer of goods from ships to storage areas, they ensure that products can reach their final destinations in a timely manner. This efficiency is particularly vital in industries such as retail, automotive, and electronics, where delays can result in significant financial losses and customer dissatisfaction.

- .

Several types of spray coating methods are commonly used

Understanding Spray Coating

The Weight of the Container A Journey into Strength and Resilience

Comment area