- Top: 3599Step on: 99

h beam cutting machine

People involved | Date:2025-08-14 18:52:57

Related articles

Next, consider the required airflow and filtration efficiency. A device with higher air changes per hour will effectively capture more pollutants. Additionally, the type of filters used (e.g., HEPA, carbon, etc.) will impact the device's efficiency and the necessity for regular maintenance.

In summary, automatic paint spraying equipment embodies a perfect confluence of experience, expertise, authoritativeness, and trustworthiness, making it an indispensable tool for industries seeking to enhance their painting processes. Its ability to deliver consistent, high-quality finishes efficiently aligns with the demands of modern production environments, solidifying its role as a cornerstone of contemporary industrial painting solutions.

Streamlining Production with Automatic Spray Painting Machine Projects

- Wall-Mounted Collectors These fixed units are ideal for workshops with dedicated welding stations. They capture fumes from fixed workstations and are often more powerful than portable units.

Choosing the Right System

- Mobile or Portable Units These are versatile systems that can be moved around the worksite, making them ideal for projects that involve welding in various locations. They feature built-in fans and filtration systems.

1. Lifting Points The locations where cranes and other lifting equipment should attach to the container for safe lifting. Ensuring the correct attachment points helps prevent damage to the container and the cargo it holds.

Automatic paint dispensers revolutionize the way we approach painting projects. Imagine a scenario where precise color mixing is no longer trial and error. With these devices, exact color consistency is achievable every time. As noted by professional painters globally, this consistency not only enhances aesthetic appeal but also maintains uniformity throughout large spaces, making retouching and extending projects considerably easier.

By ensuring that the welding process is clean and efficient, manufacturers can improve productivity while meeting safety and environmental standards. With continued advancements in automation and air management, industries can achieve seamless joints in a more sustainable and efficient manner than ever before.

However, the effectiveness of smoke collectors is influenced by various factors, including the type of technology used, maintenance practices, and the specific pollutants being targeted. Continuous innovation in this field is essential to enhance the efficiency of smoke collectors and to address emerging pollution challenges. Research and development efforts are focused on creating more advanced filtration materials and systems that can better capture a broader range of pollutants.

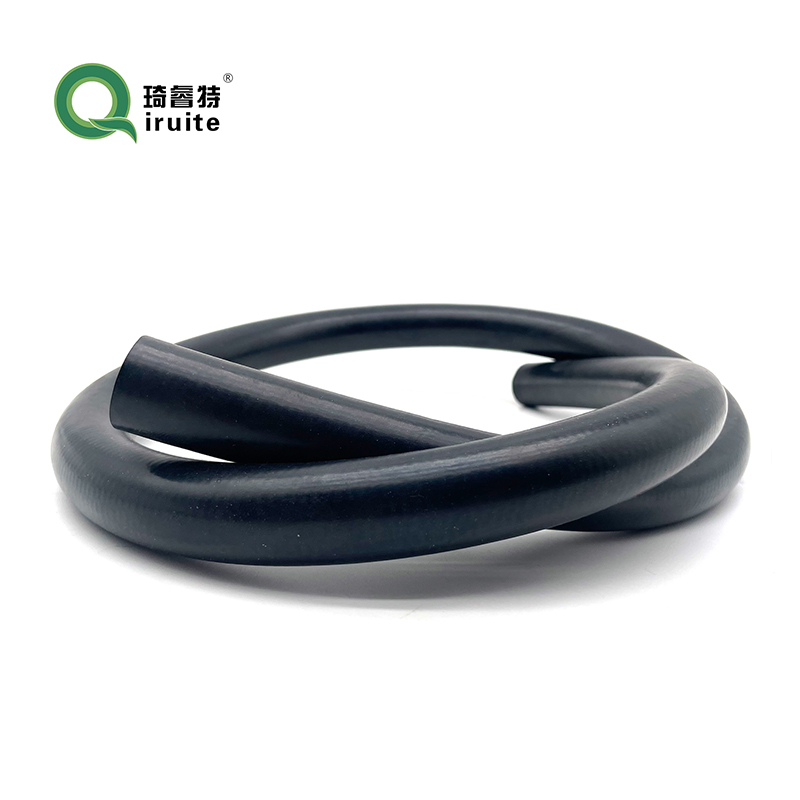

A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard

A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard Regular inspections and timely replacements can mitigate this issue Regular inspections and timely replacements can mitigate this issue

Regular inspections and timely replacements can mitigate this issue Regular inspections and timely replacements can mitigate this issue For more extensive damage, sections of the pipe might need to be replaced entirely For more extensive damage, sections of the pipe might need to be replaced entirely

For more extensive damage, sections of the pipe might need to be replaced entirely For more extensive damage, sections of the pipe might need to be replaced entirely If the power steering hose pressure drops, the steering can become stiff, making it difficult to control the vehicle, especially in emergencies If the power steering hose pressure drops, the steering can become stiff, making it difficult to control the vehicle, especially in emergencies

If the power steering hose pressure drops, the steering can become stiff, making it difficult to control the vehicle, especially in emergencies If the power steering hose pressure drops, the steering can become stiff, making it difficult to control the vehicle, especially in emergencies These innovations integrate seamlessly with the traditional mechanical functions, enhancing the driving experience and providing drivers with added peace of mind These innovations integrate seamlessly with the traditional mechanical functions, enhancing the driving experience and providing drivers with added peace of mind

These innovations integrate seamlessly with the traditional mechanical functions, enhancing the driving experience and providing drivers with added peace of mind These innovations integrate seamlessly with the traditional mechanical functions, enhancing the driving experience and providing drivers with added peace of mind

Comment area