- Top: 8Step on: 43

pasadena cool roof rebate

People involved | Date:2025-08-14 08:08:19

Related articles

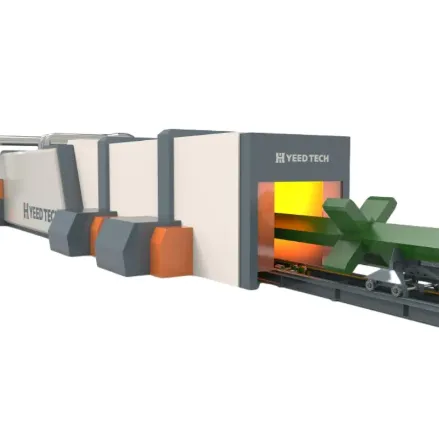

When paired with welding arms, these industrial systems create an optimal solution for large-scale welding projects. By using industrial fume extractors, manufacturers can achieve not only cleaner air but also better operational efficiency.

Automatic spray painting machines are engineered to offer consistent coating quality, essential in industries where uniformity and precision are paramount. Known for their ability to deliver an even layer of paint or coating across diverse surfaces, these machines ensure that no section is overpainted or undercoated, which is crucial in sectors such as automotive, aerospace, and consumer electronics. By minimizing human error, businesses can rely on superior finishes and enhanced durability of products, aligning with consumer expectations and stringent regulatory standards.

- Manufacturing Used for transporting raw materials and finished products within production facilities.

As the demand for precision and efficiency continues to grow, the use of robotic welding arms combined with robust extraction and ventilation systems will remain an essential part of the modern welding process. By embracing these technologies, companies can ensure that they remain at the forefront of innovation, while also providing a safer and more sustainable workplace.

Explore the Versatility of Our Small Portable Fume Extractor

- - Suction Power The effectiveness of an extractor often depends on its suction power. Select a unit that can handle the volume of fumes produced by the welding process being conducted.

2. Ease of Use These systems are designed for simplicity and effectiveness. Operators can quickly set them up and adjust their position according to the welding setup. This user-friendly approach encourages consistent use, leading to improved safety practices.

Conclusion

Welding fumes can contain a mixture of metals such as manganese, chromium, nickel, and lead, as well as ozone and nitrogen oxides, all of which are harmful. Long-term exposure to these contaminants can lead to serious health issues, including respiratory diseases, lung cancer, and neurological disorders. Furthermore, inhalation of these fume components can exacerbate pre-existing health conditions, making it essential for welders to work in safe environments.

Comment area