- Top: 42Step on: 5176

garden tomato cages

People involved | Date:2025-08-14 04:45:37

Related articles

Applications in Skyscraper Construction

What are Welding Fume Extractors?

Steel structures, known for their strength and longevity, require proper maintenance to withstand the elements and retain their visual appeal over time. One of the most effective methods for protecting and enhancing these structures is steel structure painting. This process not only improves the aesthetic quality of buildings and bridges but also plays a crucial role in extending the life of steel by preventing corrosion.

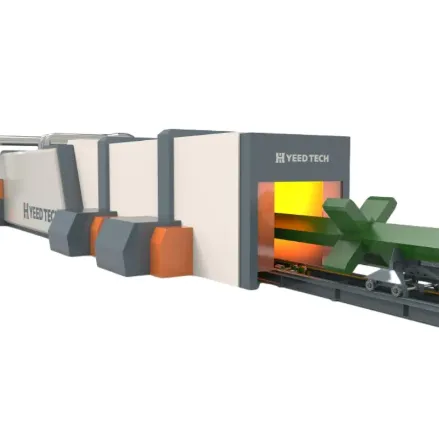

From an expertise standpoint, these systems incorporate cutting-edge software that allows for precise control over spray patterns, speeds, and volumes. Such precision minimizes waste and environmental impact, aligning with global sustainability goals. This is essential for companies looking to balance high-quality outputs with environmental responsibility.

automated spray coating systems- Enhanced Productivity Cleaner air quality can lead to fewer health-related absences among workers, fostering a more efficient and productive work environment.

Automatic spray painting systems with conveyors further enhance safety by creating a physical separation between workers and hazardous operations. With automated equipment handling the painting process, employees can focus on other tasks in a safer environment. This shift not only reduces health risks but also boosts overall morale and job satisfaction.

2. Speed and Efficiency Robotic welding arms can significantly increase production rates. They operate faster than human workers and can work continuously without fatigue, leading to higher throughput and lower operational costs. This efficiency is particularly beneficial in high-volume manufacturing environments.

- 2. Prototype Development Create a prototype of the automatic paint spraying system, enabling initial testing and adjustments.

What is a Steel Floor System?

Comment area