- Top: 54249Step on: 99395

Shijiazhuang TangChao Metal lowering coil springs

People involved | Date:2025-08-14 04:44:57

Related articles

Our inventory features a wide variety of container handling equipment designed to accommodate various capacities and operational needs. Whether you are a small business or a large logistics provider, we have the solutions to meet your specific requirements.

In conclusion, exhaust ventilation plays a vital role in maintaining a safe and healthy welding environment. As the welding industry continues to grow, the need for effective ventilation systems becomes increasingly apparent. By adopting appropriate ventilation strategies and adhering to best practices, industries can protect their workers from the harmful effects of welding fumes. Ultimately, ensuring the health and safety of workers not only enhances productivity but also contributes to a more sustainable and responsible workplace.

There are several types of ventilation systems that can be employed in robotic welding environments

. Each system has its advantages and is suited to different application needs.Achieving a Clean and Safe Workspace with Welding Smoke Extractors

- Ductwork Proper ducting channels the extracted fumes away from the work area and toward the filtration system, contributing to overall efficiency.

In summary, automatic spray coating machines represent a crucial investment for any industry focused on enhancing production quality and efficiency. By leveraging cutting-edge technology and comprehensive support, these machines offer unparalleled benefits that are recognized by experts and trusted by leading manufacturers worldwide. With their ability to deliver consistent and high-quality results, they are not just machines; they are the cornerstone of a modern, efficient, and competitive manufacturing operation.

Manufacturers sourcing these systems often seek the authoritative guidance of industry experts to maximize their investment. Consulting with specialists ensures the selection of equipment that aligns with the specific needs of an operation, particularly in terms of scale, operational speed, and material type. This strategy mitigates potential mismatches that could compromise production efficiency.

automated spray coating systems- - Filters After capturing the fumes, the system uses filters to clean the air. Various filter types, including HEPA filters, are utilized to trap particulates as small as 0.3 microns, ensuring high-level purification.

Conclusion

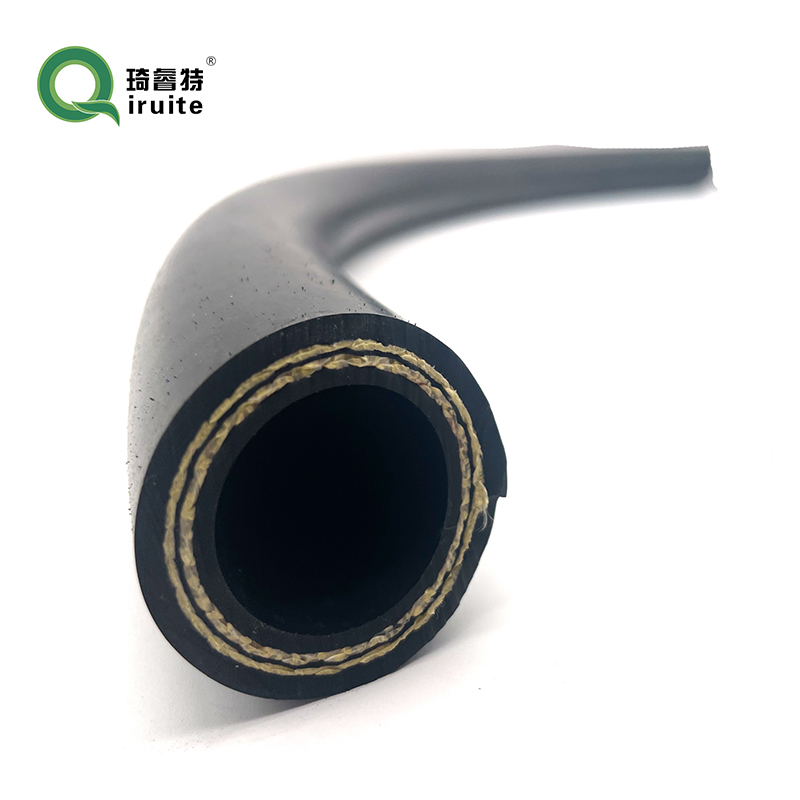

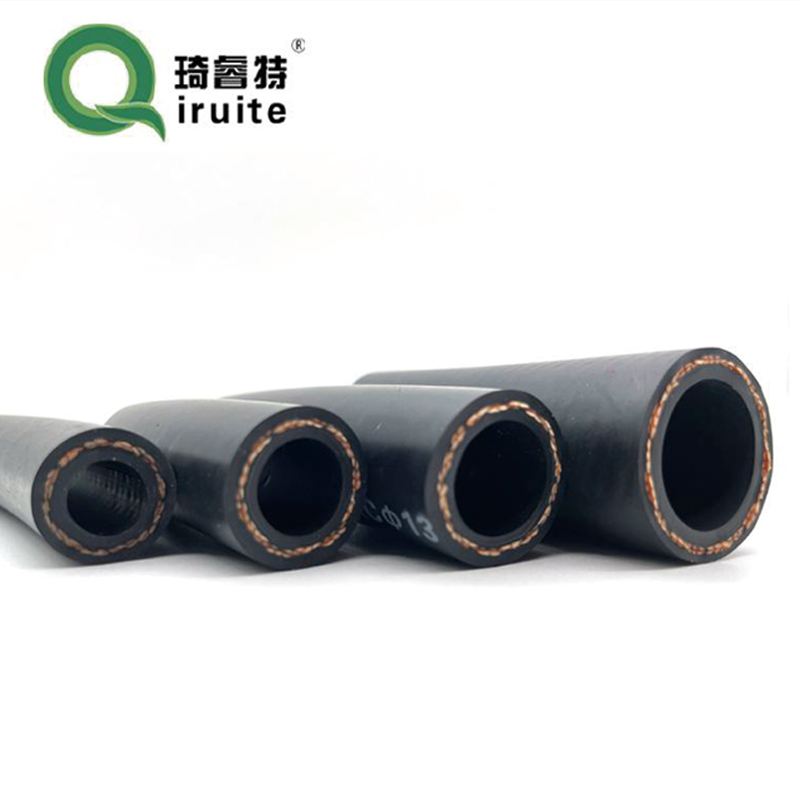

The mechanic will need to drain the power steering fluid, disconnect the old hose, and install a new one The mechanic will need to drain the power steering fluid, disconnect the old hose, and install a new one

The mechanic will need to drain the power steering fluid, disconnect the old hose, and install a new one The mechanic will need to drain the power steering fluid, disconnect the old hose, and install a new one

Their robust construction is essential to prevent any disruptions in the power steering system, which could lead to steering difficulties or even total failure Their robust construction is essential to prevent any disruptions in the power steering system, which could lead to steering difficulties or even total failure

Their robust construction is essential to prevent any disruptions in the power steering system, which could lead to steering difficulties or even total failure Their robust construction is essential to prevent any disruptions in the power steering system, which could lead to steering difficulties or even total failure

Comment area