- Top: 921Step on: 6374

guindaste para levantar contêiner

People involved | Date:2025-08-14 05:15:58

Related articles

With increasing regulations and a growing focus on worker safety, welding fume collectors have become indispensable in industries such as manufacturing, automotive, and construction. By providing welders with cleaner, healthier working conditions, these systems contribute to improved safety standards and long-term well-being.

Moreover, innovations in steel production have led to the creation of stronger, lighter materials that require fewer resources to manufacture. Techniques such as advanced alloying and the use of electric arc furnaces have made the process more eco-friendly, further solidifying steel's place in the sustainable construction movement.

As technology continues to evolve, the automatic ink dispenser market is poised for further advancements. Here are some trends that we can expect to see in the coming years

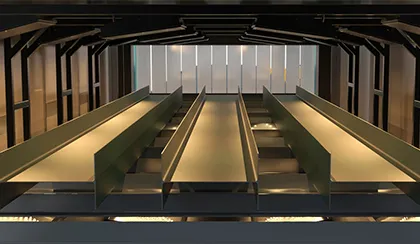

- 3. Conveyor Belts Many machines integrate conveyor systems to move items through the coating process automatically, ensuring efficiency and consistency.

1. Type of Welding Different welding processes produce varying amounts and types of fumes. For instance, MIG and TIG welding generate different fume profiles than stick welding.

The elevation marking system for ISO containers will remain a fundamental aspect of this process. Continued adherence to international standards ensures that all players in the logistics chain, from shipping lines to port operators, have a common understanding of how to handle containers safely and effectively.

In addition to improving efficiency and precision, automatic spray painting systems contribute to sustainability efforts by reducing waste and energy consumption. Traditional methods often lead to overspray and wasted materials, but these automated systems are designed to optimize every aspect of the painting process.

Comment area