- Top: 658Step on: 88

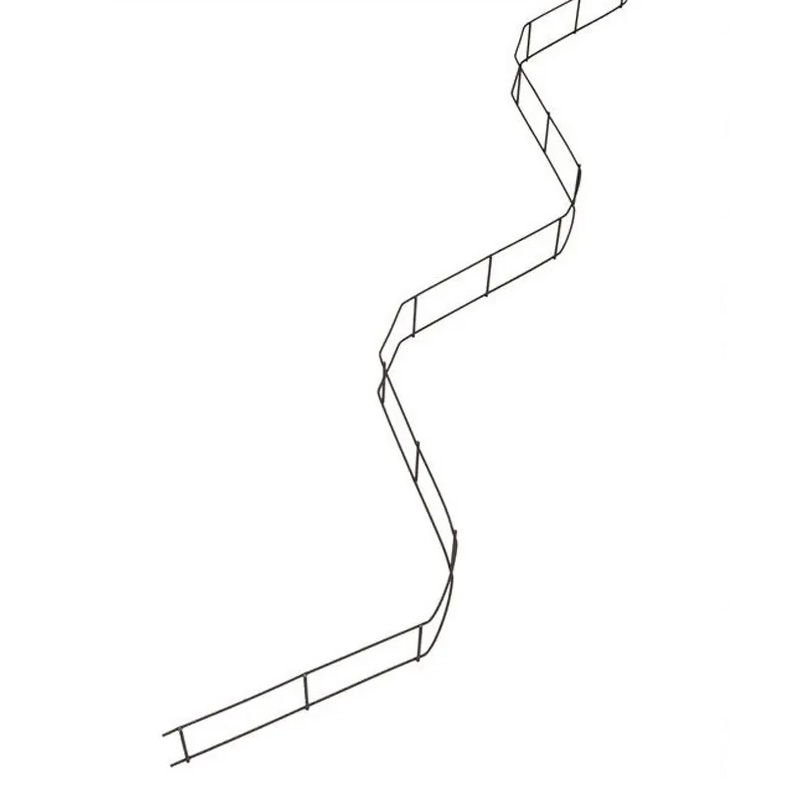

cow fence

People involved | Date:2025-08-14 05:07:58

Related articles

5. User-Friendly Interface Most modern machines come with intuitive interfaces, allowing operators to program and operate the machinery with ease. This feature helps streamline the training process for new employees and enhances overall productivity.

Initially, automated paint spraying systems were limited and often involved expensive and bulky machinery. However, advancements in robotics, nanotechnology, and artificial intelligence have given rise to more compact, sophisticated robots capable of performing intricate tasks. With rapid technological advancements, today's paint spraying robots are more accessible and versatile than ever before.

An exhaust arm is a flexible ducting system that captures fumes, smoke, and harmful particles produced during welding. It consists of a series of segments that can be adjusted to reach different angles and positions, allowing welders to work comfortably while minimizing their exposure to hazardous substances. The system is usually connected to a fume extraction unit, which filters and cleans the air before recirculating it back into the workspace or exhausting it outside.

Modern H-beam cutting machines incorporate advanced technology that enhances their performance. Here are some of the key features that make these machines indispensable

3. Design Flexibility Steel floor systems offer architects and engineers a high degree of design flexibility. The ability to span large distances without the need for intermediate supports opens up possibilities for innovative layouts and open floor designs. This is especially crucial in modern office buildings and shopping complexes.

Tailored Solutions with Automatic Paint Spraying Machines

Choosing the Right System

Several features make the Górny Podnośnik a preferred choice in lifting solutions

It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out

It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out

Comment area