- Top: 81125Step on: 41759

Shijiazhuang TangChao Metal wall ties masonry

People involved | Date:2025-08-14 04:07:54

Related articles

The implementation of the automatic paint spraying equipment is anticipated to yield numerous benefits

- - Environmental Impact The system will be designed to optimize paint usage and incorporate eco-friendly materials to minimize environmental harm.

To maximize the effectiveness of Rauchabsaugung during MIG welding, certain best practices should be followed

Looking ahead, the potential for automatic spray painting technology to evolve is immense. The integration of artificial intelligence and machine learning could lead to even greater advancements, with systems capable of adapting to different materials and surface types automatically. Innovations like 3D printing may also intersect with spray painting, allowing for complex and customized designs that were previously not feasible.

5. Flexibility and Adaptability Modern painting robots are equipped with advanced programming that allows them to handle a variety of tasks and adapt to different shapes and sizes. They can easily switch between different paint types, colors, and applications, making them suitable for diverse industries, including automotive, aerospace, and furniture manufacturing.

Objectives

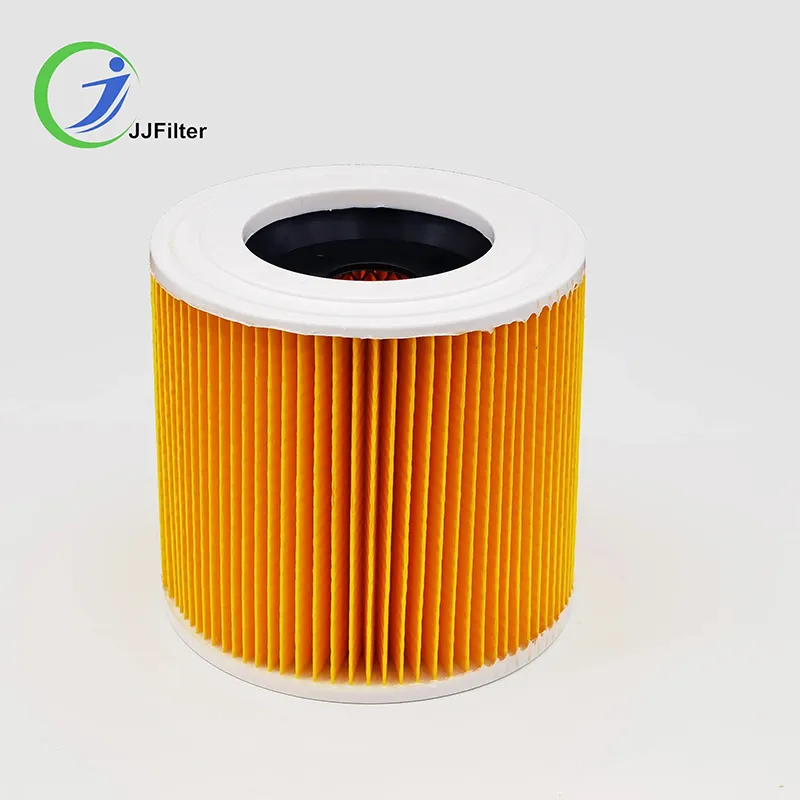

1. Local Exhaust Ventilation (LEV) Systems These systems are strategically placed near the welding operation to capture fumes at the source. LEV systems employ hoods, ducts, and filters to draw in contaminated air and remove harmful particles before they can spread throughout the workplace. The effectiveness of LEV systems depends on their design and the proximity of the fume hood to the welding operation. Proper maintenance and regular checks are also necessary to ensure optimal performance.

Comment area