- Top: 2Step on: 9

Shijiazhuang TangChao Metal long length extension springs

People involved | Date:2025-08-14 17:45:13

Related articles

In conclusion, robotic welding arms represent a significant leap forward in manufacturing technology. Their precision, efficiency, and safety features make them invaluable assets to modern production lines. As technology continues to evolve, the role of these robotic systems is expected to expand, further solidifying their importance in the future of manufacturing. Companies that embrace this technology will likely find themselves better positioned to compete in an increasingly automated and competitive global market.

- Bridges Given their strength and durability, steel floor systems are extensively used in bridge construction, supporting heavy vehicle traffic and ensuring longevity.

- 2. Prototype Development Create a prototype of the automatic paint spraying system, enabling initial testing and adjustments.

Additionally, our skilled team is always on hand to provide expert advice and support. From selecting the right equipment to ongoing maintenance, we are dedicated to aiding your business's growth and operational efficiency.

Proficiency in utilizing automatic spray painting technology requires an understanding of its technical capabilities and maintenance procedures

. Regular calibration and maintenance are vital to ensure long-term operational efficiency. Industry experts advocate for routine check-ups to avert potential defects and ensure consistent performance. This proactive approach not only prolongs the machine's lifespan but also fortifies trustworthiness among clients seeking reliable and flawless finishes.

automatic spray painting machineفوائد استخدام النظام

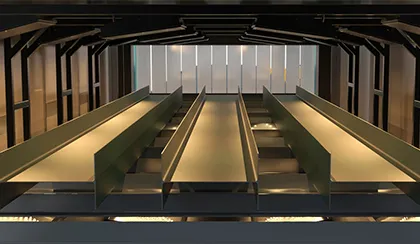

Project Proposal for Automatic Paint Spraying Equipment

Why should you choose Yeed Tech Co., Ltd. for your automatic spray painting needs? Our commitment to quality and customer satisfaction sets us apart. Each piece of equipment undergoes rigorous testing to ensure reliability, performance, and longevity. Furthermore, our team of experts is dedicated to providing you with exceptional support and guidance from the initial inquiry to post-purchase training.

- Local Exhaust Ventilation (LEV) This system captures fumes at the source, such as through hoods or ducts placed near the welding area. LEV is particularly effective in reducing exposure as it targets the pollutants before they disperse into the surrounding environment.

Comment area