- Top: 73587Step on: 6891

Hebei Chida cool roof sika

People involved | Date:2025-08-14 03:35:52

Related articles

- 3. Reducing Labor Costs To minimize the manual labor required for painting tasks, freeing up skilled workers for more complex operations.

ข้อดีของการใช้แผ่นโลหะลอน

Key Components of an ISO Container Survey

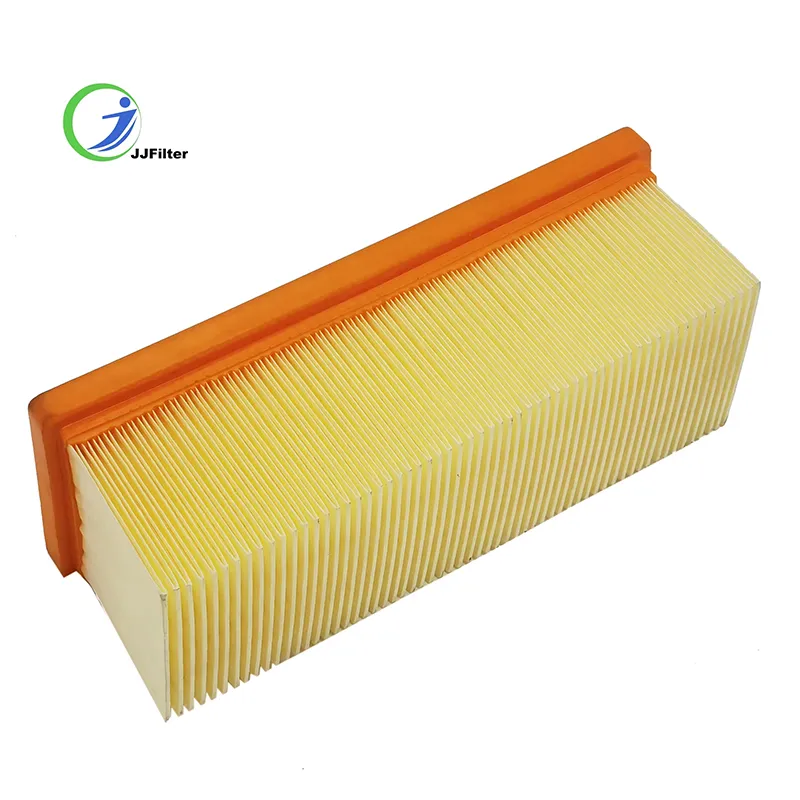

Authoritativeness is underscored by the widespread endorsement of automatic paint spraying equipment by industry leaders and specialists. Numerous case studies highlight significant improvements in safety and environmental compliance. These machines typically incorporate advanced filtration systems that minimize overspray and reduce volatile organic compound (VOC) emissions. By adhering to stringent environmental regulations while enhancing workplace safety conditions, these systems have become the preferred choice in industries focused on sustainability and safety.

automatic paint spraying equipment- .

The integration of steel structure manufacturing equipment with automatic spray painting systems has transformed how manufacturers handle large-scale production. These machines provide consistent and even coatings, ensuring that every piece meets stringent quality standards.

4. Adequate Ventilation In addition to localized fume extraction systems, ensure that the overall workspace is well-ventilated. This helps to dilute the concentration of harmful substances in the air.

Beyond the technological advancements, user experiences highlight the transformative impact of automatic paint spraying solutions. Operators have access to training modules and user-friendly interfaces, making it accessible even to those newly acquainted with automated systems. These machines are equipped with safety features such as automatic shut-off and containment systems to prevent accidents and ensure compliance with environmental regulations. Such thoughtful design not only protects the workforce but also builds trust in the machinery and its capabilities.

Environmental Considerations

Comment area