- Top: 28Step on: 2853

black chain link fencing cost

People involved | Date:2025-08-14 04:32:56

Related articles

Conclusion

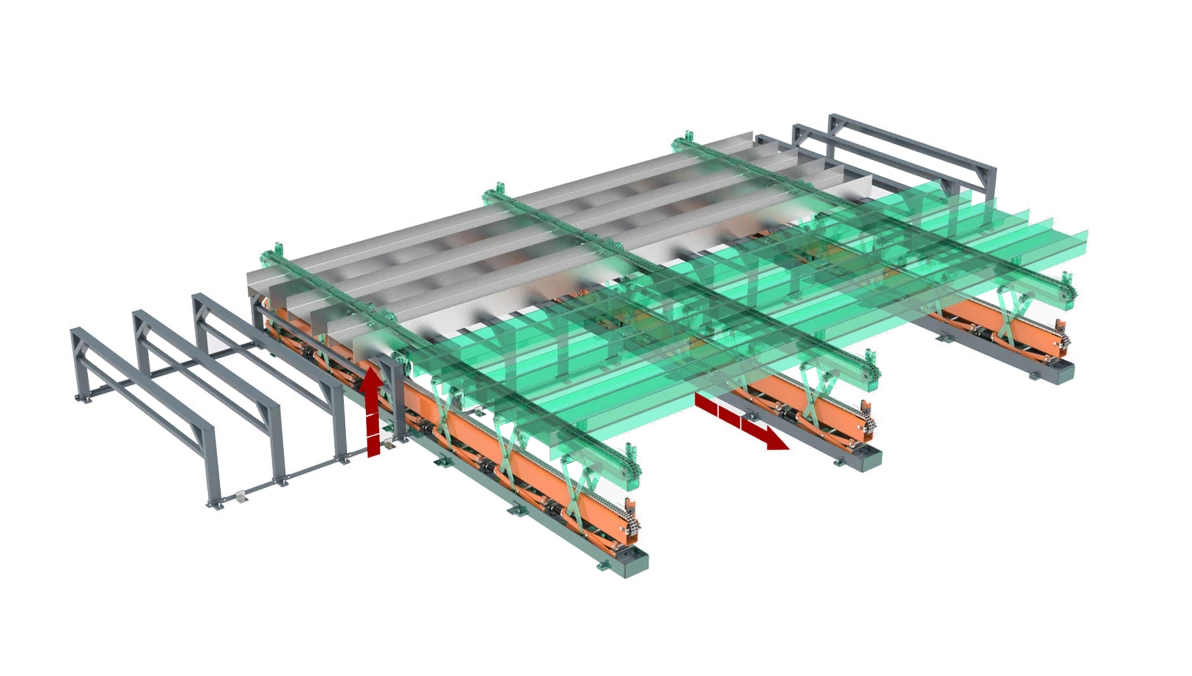

Automatic paint spraying equipment not only enhances the speed of operations but also ensures accuracy and resource optimization. These machines are equipped with advanced nozzles and adjustable settings, allowing manufacturers to customize the spray pattern, volume, and speed according to their specific needs.

By automating the painting process, businesses can reduce manual labor and increase output without compromising precision. Additionally, automation minimizes errors, leading to reduced material waste and cost savings. In industries where steel structure painting is crucial, these machines enhance not only efficiency but also the lifespan of the components.

In larger facilities, welding exhaust fans are essential for maintaining a clean and safe working environment. These fans help circulate air, removing welding fumes and smoke that might otherwise linger in the workspace.

- Industrial Facilities Warehouses and manufacturing plants benefit from the heavy load-bearing capabilities of steel floors. The ability to incorporate heavy machinery without compromising structural integrity makes this a popular choice.

- Regular Maintenance Maintenance is key to ensuring efficiency. Regularly check and clean filters, ducts, and fans to remove built-up dust and debris, which can obstruct airflow.

However, successful integration of automatic spray painting systems requires thorough training and expertise. Operators must understand the intricacies of machine settings, maintenance protocols, and troubleshooting to maximize efficacy. Investing in training programs thus becomes an essential component of leveraging this technology.

Over the years, there has also been a significant evolution in exhaust technology. Manufacturers are continually innovating to create lighter and more efficient exhaust systems that do not compromise performance. For instance, the introduction of stainless steel and other durable materials has led to systems that not only last longer but also enhance performance by reducing back pressure, which can impede engine efficiency.

Welding ventilation works in harmony with welding fume extraction systems to create an efficient, integrated solution. By combining localized extraction with facility-wide ventilation, manufacturers can achieve optimal air quality while minimizing energy consumption.

Comment area