- Top: 1Step on: 4

containerlyftande spridarbalk

People involved | Date:2025-08-14 04:12:15

Related articles

2. Consistent Quality Automated systems ensure that the coating application is uniform across different surfaces, reducing the variability often seen in manual processes. This consistency leads to higher quality finishes and fewer product defects.

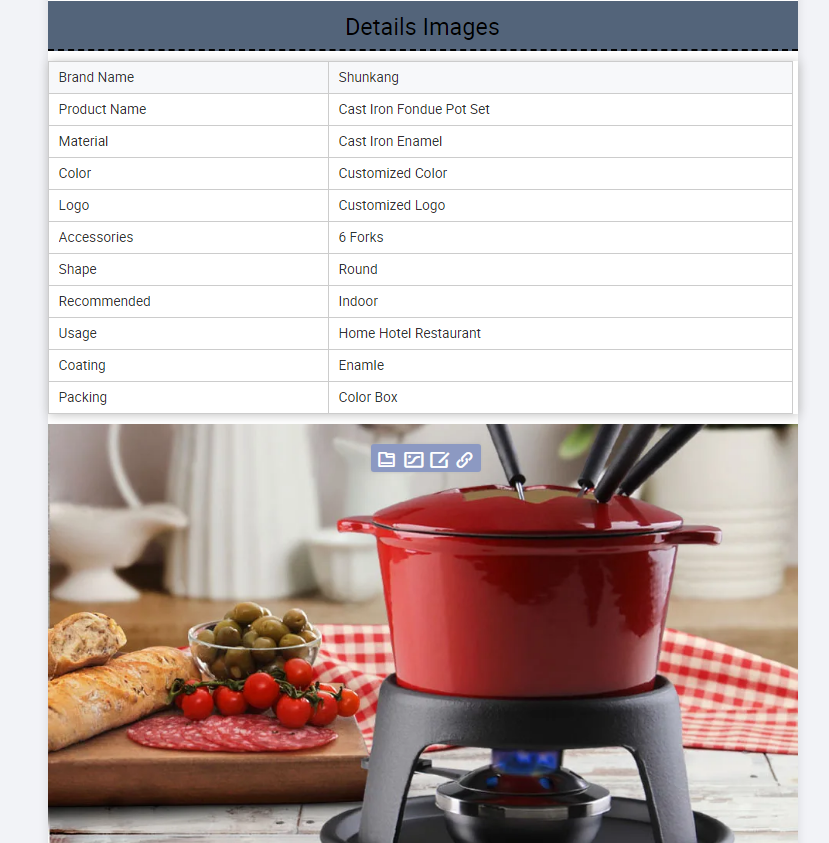

3. Cast Iron Rods Cast iron rods are specifically formulated for welding cast iron components. They are essential in repairs where cast iron pots, pipes, or machinery need to be joined or mended.

The Górny Podnośnik Elevating Standards in Lifting Technology

However, flawless welding is not just about precision in the welding process; it’s also about maintaining a safe and clean working environment. Fume extraction equipment, like smoke collectors and welding fume filters, play a critical role in ensuring that workers are not exposed to harmful welding fumes. These systems work by capturing smoke and fumes at the source, preventing them from circulating in the air and affecting the workers’ health.

- 2. Control System An electronic unit that allows users to program specific parameters such as spray patterns, speed, and coating thickness.

- 2. Prototype Development Create a prototype of the automatic paint spraying system, enabling initial testing and adjustments.

The Advantage Of Yeed Tech Co., Ltd.

In conclusion, tower steel is a fundamental component of modern construction, especially in the development of skyscrapers and other tall structures. Its unique properties, combined with its environmental advantages, make it a preferred choice for engineers and architects around the world. As the global landscape continues to evolve, the importance of tower steel will only grow, ensuring that it remains a cornerstone of architectural advancement for years to come. The future of construction, with its endless possibilities, is unquestionably tied to the strength and resilience of tower steel.

4. Regular Monitoring Conducting regular monitoring of the air quality in welding environments can help identify hazardous levels of particulates and ensure compliance with occupational safety standards. This monitoring should include assessments for specific contaminants present in weld smoke.

This makes them a healthier option for cooking meals for you and your family This makes them a healthier option for cooking meals for you and your family

This makes them a healthier option for cooking meals for you and your family This makes them a healthier option for cooking meals for you and your family Its handle is designed for comfort and ease of use, allowing cooks to apply pressure without straining their hands or wrists Its handle is designed for comfort and ease of use, allowing cooks to apply pressure without straining their hands or wrists

Its handle is designed for comfort and ease of use, allowing cooks to apply pressure without straining their hands or wrists Its handle is designed for comfort and ease of use, allowing cooks to apply pressure without straining their hands or wrists

Titanium frying pans are made from strong, lightweight materials and are known for their non-stick properties and fast heating capabilities. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to warping and have a limited lifespan.

Titanium frying pans are made from strong, lightweight materials and are known for their non-stick properties and fast heating capabilities. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to warping and have a limited lifespan.

Comment area