- Top: 58Step on: 23

asphalt shingle tile

People involved | Date:2025-08-14 09:27:54

Related articles

- Reach Stackers: Ideal for stacking containers in tight spaces while maintaining stability.

2. Speed and Efficiency Robotic welding arms can significantly increase production rates. They operate faster than human workers and can work continuously without fatigue, leading to higher throughput and lower operational costs. This efficiency is particularly beneficial in high-volume manufacturing environments.

In the welding industry, health and safety are paramount concerns. One of the critical challenges that welders face is exposure to harmful fumes generated during the welding process. These fumes consist of various toxic metals and gases that can pose serious health risks if inhaled over an extended period. This is where a welding fume extractor comes into play. These specialized devices play a vital role in improving air quality and safeguarding the health of workers in welding environments.

- Commercial Buildings High-rise office buildings often utilize steel floor systems to create open and flexible workspaces. The speed of construction and design versatility allows for rapid development.

Conclusion

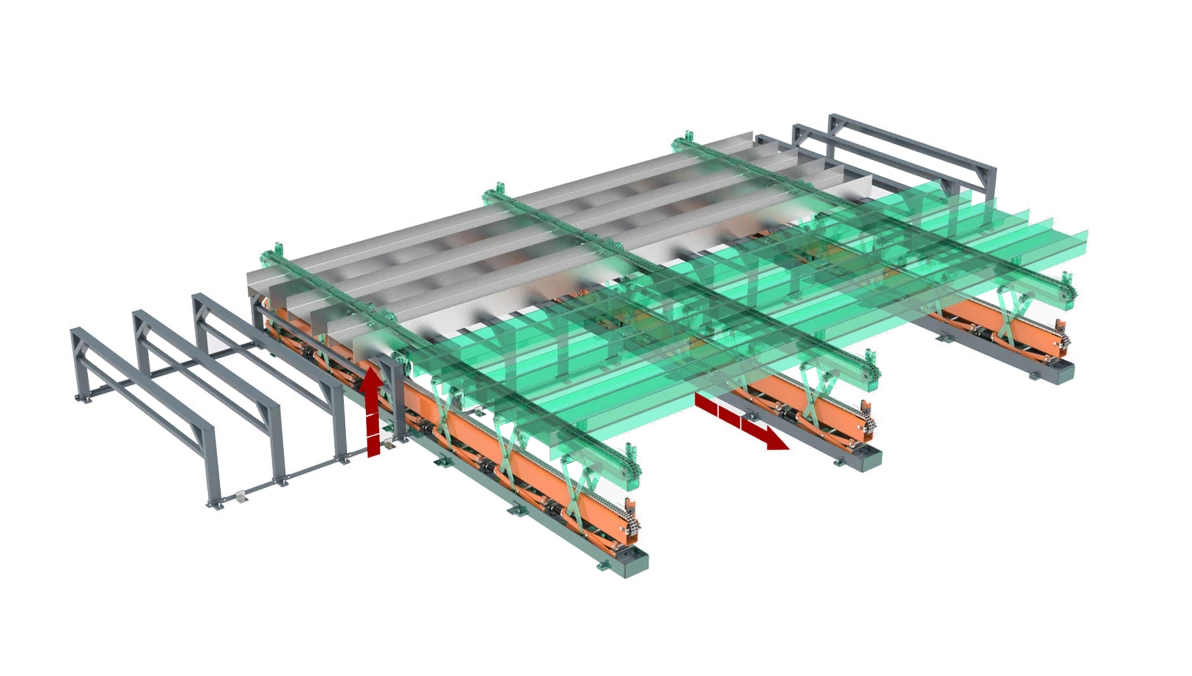

Why an Automatic Spraying Line is Essential for Modern Production

The expertise embodied in modern paint spraying equipment is evident in its adaptability and precision. Contemporary machines often come equipped with computerized controls and sensors that adjust spray patterns and flow rates in real-time, responding to the nuances of the surface being coated. This level of precision reduces material wastage and ensures optimal use of paints and coatings, which not only cuts down on production costs but also contributes positively to environmental sustainability efforts—a crucial consideration for companies striving to align with green manufacturing practices.

automatic paint spraying equipmentExploring the Importance of Exhaust Systems in Modern Vehicles

They are also easy to install and integrate into existing systems They are also easy to install and integrate into existing systems

They are also easy to install and integrate into existing systems They are also easy to install and integrate into existing systems

Comment area