- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Янв . 14, 2025 15:35

Back To List

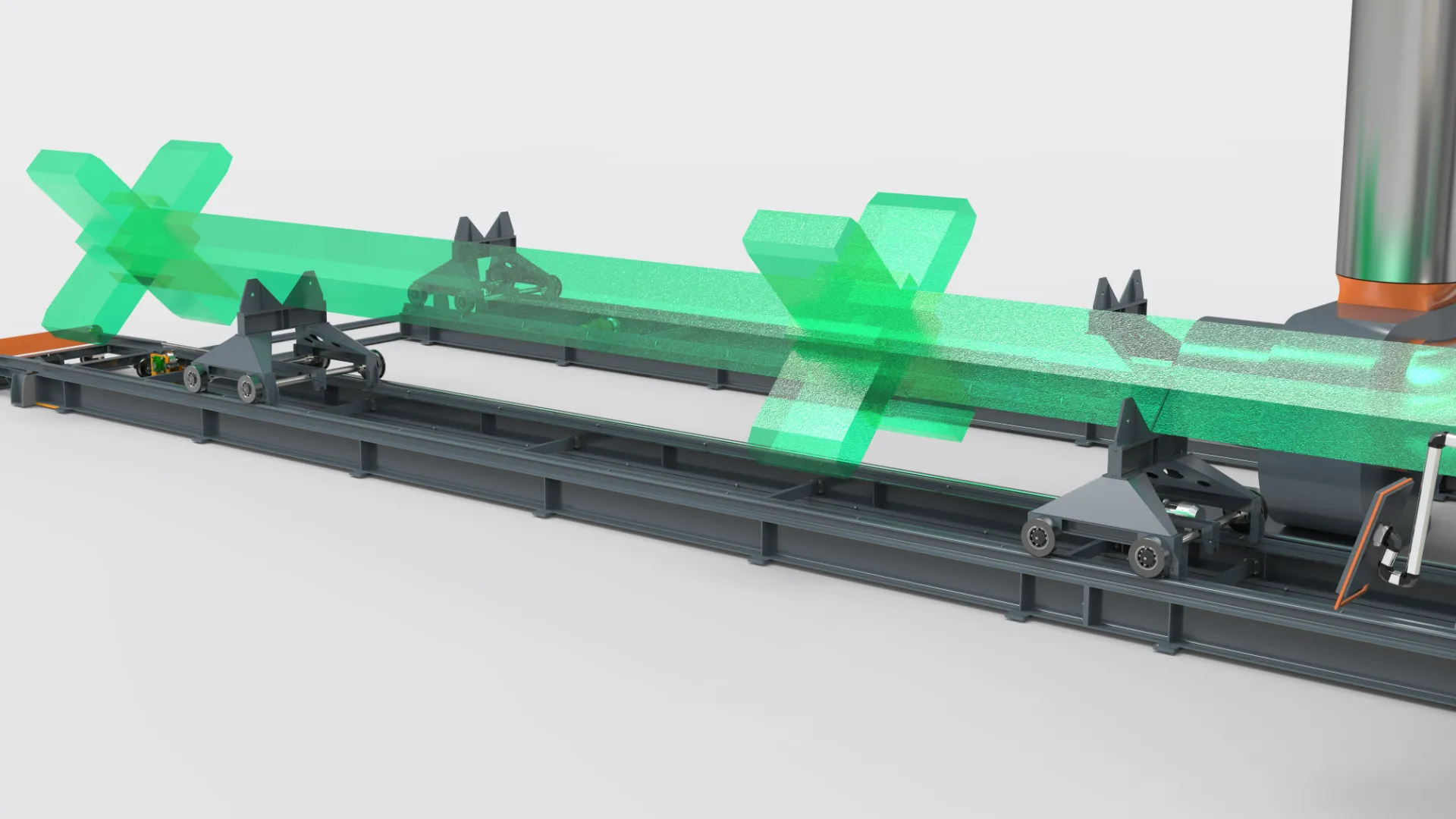

Heavy Steel Structure Painting Line

The world of automotive painting has undergone significant transformations with technological advancements spearheading enhanced efficiency and precision. Central to these innovations is the automated paint spray system, a marvel driving the industry towards unmatched quality and productivity.

Trustworthiness in automated paint spray technology is bolstered by its compliance with global quality and safety standards. These systems are frequently subjected to rigorous testing and certifications, assuring users of their dependability and safety. Integrating with advanced diagnostics, they provide real-time monitoring and feedback mechanisms, enabling swift identification and resolution of any operational hitches. This feature not only extends the lifespan of the equipment but also fosters a culture of proactive maintenance that can save manufacturers significant time and costs down the line. Experience from users across the globe further enriches the narrative of automated spray systems. Manufacturers who have transitioned from manual to automated processes report substantial improvements in paint utilization, reduction in labor costs, and heightened consistency in product quality. These experiential insights contribute to the establishment of best practices and aid in refining existing technologies, driving the evolution of automated painting systems onward. In summary, the adoption of automated paint spray systems is not merely a step forward in technological integration but a leap towards sustainability, precision, and efficiency for the automotive industry. Professionals and businesses aiming to elevate their production processes will find in these systems a harmonious blend of cutting-edge technology and practical application. As the industry moves forward, embracing such innovations will not only boost productivity but also reinforce a commitment to quality, positioning brands at the forefront of the competitive auto market landscape.

Trustworthiness in automated paint spray technology is bolstered by its compliance with global quality and safety standards. These systems are frequently subjected to rigorous testing and certifications, assuring users of their dependability and safety. Integrating with advanced diagnostics, they provide real-time monitoring and feedback mechanisms, enabling swift identification and resolution of any operational hitches. This feature not only extends the lifespan of the equipment but also fosters a culture of proactive maintenance that can save manufacturers significant time and costs down the line. Experience from users across the globe further enriches the narrative of automated spray systems. Manufacturers who have transitioned from manual to automated processes report substantial improvements in paint utilization, reduction in labor costs, and heightened consistency in product quality. These experiential insights contribute to the establishment of best practices and aid in refining existing technologies, driving the evolution of automated painting systems onward. In summary, the adoption of automated paint spray systems is not merely a step forward in technological integration but a leap towards sustainability, precision, and efficiency for the automotive industry. Professionals and businesses aiming to elevate their production processes will find in these systems a harmonious blend of cutting-edge technology and practical application. As the industry moves forward, embracing such innovations will not only boost productivity but also reinforce a commitment to quality, positioning brands at the forefront of the competitive auto market landscape.

Prev:

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025