- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

How Can Automatic Spray Painting Robots Transform Your Manufacturing Process?

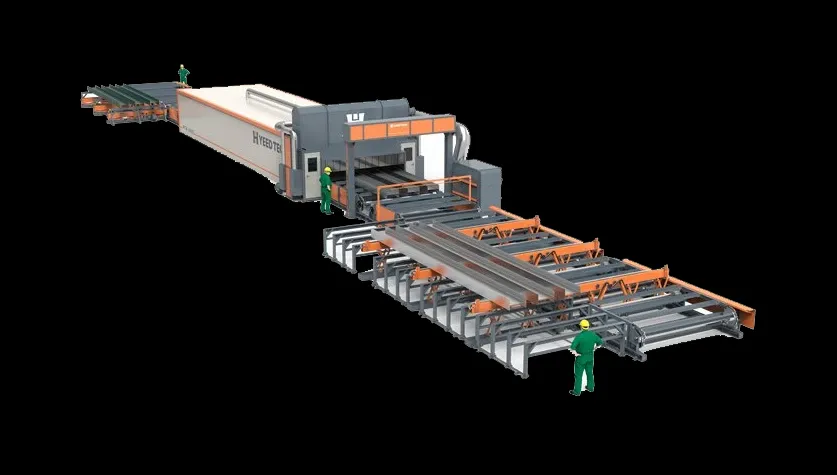

In today’s rapidly advancing industrial landscape, the efficiency and precision of coating processes are more important than ever. For manufacturers in the steel structure industry, achieving consistent, high-quality finishes can be a daunting challenge. Fortunately, the advent of the automatic spray painting robot has revolutionized the way companies approach painting and coating. This cutting-edge technology provides an automated solution that not only enhances productivity but also ensures uniform quality across all produced components.

What Makes the Automatic Spray Painting Robot a Game-Changer for Steel Industries?

The automatic spray painting robot offers numerous advantages for industries that require large-scale steel coating. Unlike manual spraying, where human error can lead to uneven coating and excessive paint wastage, robots are programmed to deliver consistent and precise results. This reduces both material costs and the need for rework, making the process more efficient and eco-friendly. By automating the painting process, manufacturers can also improve safety, as the robots can operate in environments where toxic fumes or hazardous conditions might pose risks to human workers.

How Does the Awtomatlaşdyrylan boýag prosesi Improve Production Efficiency?

Adopting an Awtomatlaşdyrylan boýag prosesi dramatically enhances production efficiency by removing bottlenecks caused by manual labor. Robots work continuously, ensuring the painting task is completed in a fraction of the time compared to traditional methods. With minimal downtime and a consistent output, businesses can ramp up production while reducing labor costs. Moreover, the process can be fine-tuned to accommodate various painting techniques and materials, further enhancing flexibility and scalability for manufacturers working with different steel products.

What Are the Advantages of Using a Painting System in Steel Structure Processing?

A well-integrated reňk ulgamy plays a crucial role in ensuring that every component undergoes a uniform and durable coating. By employing an automated painting system, manufacturers can achieve precise paint application on every steel piece, ensuring the final product meets high-quality standards. This system can also be programmed to accommodate specific paint types, ensuring the right solution is applied depending on the environment the finished product will be exposed to. Whether it’s for outdoor exposure or protection from corrosive elements, a specialized painting system offers tailored solutions for various needs.

Can Steel Structure Processing Equipment Benefit from Advanced Robotics?

Yes, polat gurluşy gaýtadan işleýän enjamlar can greatly benefit from the integration of robotic technology. By combining automation with steel structure processing, businesses are able to streamline their workflows. Robots can handle tasks such as coating, finishing, and even material handling, leading to increased throughput and improved consistency. Additionally, the precision offered by robots ensures that every surface is coated effectively, which is crucial for the longevity and strength of the steel structure once it's in use.

How Do Equipment for the Steel Structure Industry Improve Overall Productivity?

The evolution of equipment for the steel structure industry is a direct response to the growing demand for efficiency and precision in steel fabrication. By implementing advanced robotic systems in the production line, manufacturers can reduce the manual effort required, leading to faster turnaround times and higher output. These systems also enhance the accuracy of steel component measurements, ensuring that all parts fit together perfectly in the final assembly. The result is not only higher productivity but also a reduction in errors and material waste.

What Are the Key Benefits of Automatic Spray Painting Robots in Coating Applications?

The primary benefit of awtomatiki pürküji reňkli robotlar is their ability to ensure a high degree of consistency and quality. By maintaining uniform spray patterns and minimizing overspray, these robots are able to deliver superior coatings that meet stringent industry standards. Their precision makes them particularly useful for coating large or complex steel structures, which might otherwise require multiple manual touches to achieve the same result.

How Does an Awtomatlaşdyrylan boýag prosesi Improve Sustainability in Manufacturing?

An awtomatiki reňklemek prosesi significantly reduces paint waste by optimizing the spray technique and ensuring that the paint is applied only where needed. This leads to lower consumption of resources and a more sustainable production process. Additionally, automation allows for better control over air quality and ventilation, reducing harmful emissions associated with traditional manual painting processes. As industries continue to prioritize sustainability, these automated solutions play a vital role in reducing environmental impact.

Automatic Spray Painting Robot FAQs

Q: How does the automatic spray painting robot improve quality control in painting?

A: The automatic spray painting robot ensures precise, uniform coating across all steel components. Its repeatability eliminates the variations found in manual spraying, leading to higher quality and fewer defects.

Q: Can an awtomatiki reňklemek prosesi be used for different types of steel?

A: Yes, an awtomatiki reňklemek prosesi can be customized to work with various types of steel. The system can be programmed to accommodate different paint types and application techniques, depending on the steel’s intended use.

Q: What types of industries benefit most from reňk ulgamlary?

A: Industries that deal with large-scale production of steel components, such as construction, automotive, and manufacturing, benefit greatly from reňk ulgamlary. These systems ensure high throughput, consistent quality, and reduced labor costs.

Q: How does polat gurluşy gaýtadan işleýän enjamlar improve production efficiency?

A: Steel structure processing equipment integrates automation to speed up the manufacturing process, reduce errors, and improve the precision of each steel component. This results in faster production times and higher overall efficiency.

Q: Is it difficult to implement equipment for the steel structure industry in an existing production line?

A: Integrating equipment for the steel structure industry into an existing production line is relatively straightforward, especially with modern systems designed for compatibility. Automation specialists can help with the transition to ensure minimal disruption and maximum efficiency gains.

Önümleriň kategoriýalary

Iň soňky habarlar

-

Unmatched Mobility and Efficiency in Container Handling Equipment

HabarlarJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

HabarlarJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

HabarlarJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

HabarlarJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

HabarlarJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

HabarlarJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

HabarlarMay.28,2025