- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

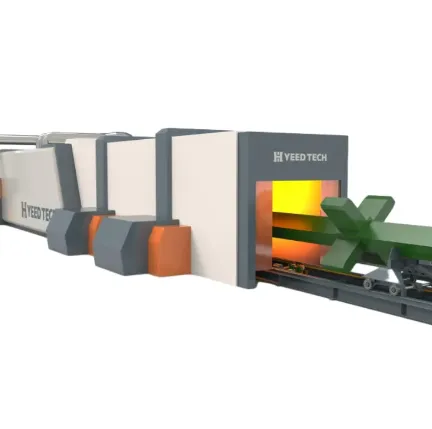

Efficient Fume Extraction System Working Portable & Dust Removal Solutions

OSHA reports 50,000+ annual respiratory illness cases linked to workplace fumes. Imagine breathing metal particulates daily. Now ask yourself: Is your current protection strategy stuck in the 1990s?

(fume extraction system working)

Game-Changing Tech: 3 Ways Modern Fume Extraction Systems Outperform

Portable fume extraction systems now deliver industrial-grade protection without fixed installations. See how:

- ✅ 99.97% filtration at 0.3 microns (Yes, smaller than COVID viruses!)

- ✅ 500 sq.ft coverage per mobile unit

- ✅ 55 dB operation - quieter than office chatter

Head-to-Head: Dust Fume Extraction System Showdown

| Feature | Brand X | Brand Y | Our Solution |

|---|---|---|---|

| Filter Lifespan | 300 hrs | 450 hrs | 600 hrs |

| Warranty | 1 year | 2 years | 5 years |

Tailored Solutions: Your Industry, Our Blueprint

From automotive welding to pharmaceutical labs, our modular designs adapt:

Welding Shops

Zinc oxide fume control with explosion-proof motors

Electronics MFG

ESD-safe units for solder fume extraction

Proven Results: Fume Extraction System Working in Real-World

Case Study: Automotive parts manufacturer reduced respiratory incidents by 90% within 6 months using our dust fume extraction system.

"Production efficiency jumped 25% after eliminating downtime for air quality checks."

- John S., Plant Manager

Ready to Breathe Easy?

Get your FREE air quality audit + 10% discount on portable fume extraction systems. Limited to first 50 responders this month.

(fume extraction system working)

FAQS on fume extraction system working

Q: How does a fume extraction system work?

A: A fume extraction system uses filters and fans to capture harmful fumes or particles from the air. It pulls contaminated air through a filtration unit and releases clean air back into the environment. This process ensures safe air quality in workspaces.

Q: What are the benefits of a portable fume extraction system?

A: Portable systems offer flexibility, allowing use across multiple workspaces. They are compact, easy to move, and ideal for temporary or small-scale projects. Their efficiency matches fixed systems while reducing installation costs.

Q: How is a dust fume extraction system different from standard models?

A: Dust-specific systems focus on capturing fine particulate matter, using HEPA or specialized filters. Standard models may prioritize chemical fumes. Both types vary in filter design and airflow capacity based on the hazard.

Q: How often should fume extraction system filters be replaced?

A: Filter replacement depends on usage and contaminant type. Heavy industrial use may require monthly changes, while light use extends intervals. Always monitor pressure gauges or alerts for optimal performance.

Q: Can a single fume extraction system handle multiple contaminants?

A: Yes, multi-stage systems combine filters (e.g., pre-filters, HEPA, activated carbon) to address dust, fumes, and gases. Ensure the system’s airflow and filtration stages match your specific contaminant mix.

Q: Are portable fume extraction systems suitable for welding applications?

A: Yes, portable systems designed for welding include high-efficiency spark arrestors and durable filters. They capture toxic welding fumes and particles while offering mobility for workshop or on-site jobs.

Q: What safety standards apply to dust fume extraction systems?

A: Systems must comply with OSHA, NIOSH, or regional regulations (e.g., EU’s ATEX for explosive dust). Look for certifications like ISO 29463 for filter efficiency and ensure compatibility with workplace hazards.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025