- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

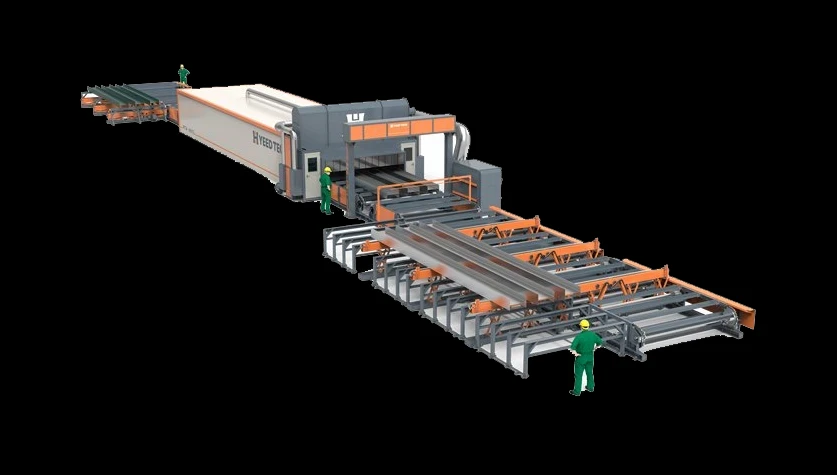

Steel Arch Painting Line 55m Automated Coating with 3D Scanning Safety

Did you know 68% of steel arch

structure failures originate from inadequate surface protection? With corrosion costing global industries $2.5 trillion annually, your painting operations can't afford guesswork. Enter the game-changing 55-meter-long automatic painting line with 3D scanning – where precision meets industrial might.

(steel arch)

Revolutionary Technology for Unmatched Protection

Our steel arch painting system delivers 40% faster cycle times than conventional methods. The integrated 3D scanning module detects surface imperfections down to 0.1mm accuracy – that's thinner than human hair! Why risk manual errors when automated perfection awaits?

Why We Outperform Competitors

| Feature | Standard Systems | Our Solution |

|---|---|---|

| Scanning Accuracy | ±2mm | ±0.1mm |

| Paint Waste | 18-22% | 4-6% |

| Safety Compliance | ISO 8501 | ISO 8501 + EN 1090 |

Tailored Solutions for Your Steel Arch Needs

Whether you're coating stadium roofs or bridge components, our modular design adapts to your workflow. Choose from three operational modes: turbo (1200㎡/hr), precision (800㎡/hr), or eco (500㎡/hr). Your project, your rules!

Proven Success Across Industries

Client X increased production output by 55% while reducing coating defects by 92%. Client Y slashed labor costs by $380,000 annually through our automated safety operation procedures. When will your success story begin?

Ready to transform your steel arch protection strategy? Claim Your Free Efficiency Audit today. For 23 years, SteelGuard Solutions has empowered manufacturers worldwide – and your victory starts with one click. Don't paint your future with yesterday's brushes!

(steel arch)

FAQS on steel arch

Q: What safety protocols are critical for operating a steel arch painting line?

A: Key protocols include proper PPE usage, ventilation compliance, and regular equipment inspections to prevent fire hazards and toxic exposure during steel arch painting operations.

Q: How does the 55-meter-long automatic painting line enhance efficiency?

A: The automated system integrates 3D scanning for precise coating application, reduces manual labor, and ensures uniform coverage across large steel structures like arches.

Q: Why is 3D scanning used in steel structure painting lines?

A: 3D scanning maps complex geometries (e.g., steel arches) to optimize spray paths, minimize material waste, and ensure full coverage in hard-to-reach areas.

Q: What steps prevent accidents in steel structure painting workflows?

A: Lockout-tagout procedures for machinery, anti-slip platforms, and continuous air quality monitoring are essential to mitigate risks during automated painting processes.

Q: How is maintenance handled for automated steel arch painting systems?

A: Scheduled cleaning of nozzles, calibration of 3D scanners, and real-time diagnostics ensure uninterrupted operation and longevity of the 55-meter automated line.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025