- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Ke Hobane'ng ha Liindasteri li Fetolela Mechineng ea ho Penta e Ikemetseng ea Spray

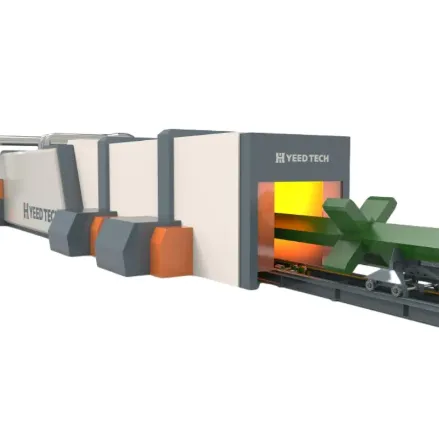

Ho amoheloa ha mechine e itirisang ea ho penta e fetola liindasteri ka potlako lefatšeng ka bophara. Ho tloha ho tlhahiso ea likoloi ho isa tlhahisong ea thepa ea ka tlung, likhoebo li ntse li fetohela lits'ebetsong tsena tse tsoetseng pele ho ntlafatsa ts'ebetso, ho netefatsa ho felloa ke maemo a holimo le ho fokotsa litšenyehelo tsa ts'ebetso. Phetoho ena e emela tlhokomeliso e ntseng e eketseha ea boleng boo mekhoa ea ho penta ka mokhoa o itekanetseng tlisa tlhahiso ea sejoale-joale.

Kamoo Mechini ea ho Penta e Iketselitsoeng e Fafatsang Kateng e Ntlafatsang Sebetsa

E 'ngoe ea mabaka a mantlha a hore liindasteri li amohelehe mechine e itirisang ea ho penta ke bokhoni ba bona ba ho nolofatsa mekhoa ea tlhahiso. Ho fapana le mekhoa ea ho penta ka letsoho, mechini ena e khona ho sebetsa e sa khaotse ka ho kenella ho fokolang ha motho. Sena se etsa bonnete ba hore lihlahisoa tse ngata li ka koaheloa hantle, ho fokotsa nako ea tlhahiso.

Kopanyo ea mokhoa oa ho penta othomathike o nang le conveyor ka ho eketsehileng e ntlafatsa katleho ena ka ho iketsetsa motsamao oa lintho ka mokhoa oa ho penta. Sena se felisa litšitiso 'me se tiisa ts'ebetso e se nang moeli, ho etsa hore litsamaiso tsena li be tse loketseng mela e phahameng ea tlhahiso. Ho feta moo, tšebeliso e nepahetseng ea pente e fokotsa litšila tsa lintho tse bonahalang, e lebisang ho bolokoeng ha litšenyehelo le ts'ebetso e tsitsitseng.

Melemo ea Automated Paint Spray Systems in Precision

Ho nepahala ho bohlokoa ho penta ea indasteri, le mechine e itirisang ea ho penta fana ka ho nepahala ho ikhethang. Litsamaiso tsena li etselitsoe ho sebelisa liphahlo ka mokhoa o ts'oanang, ho netefatsa pheletso e se nang sekoli sehlahisoa se seng le se seng. Hore na e sebetsana le meralo e rarahaneng kapa bokaholimo bo boholo, mofuta o hlophisitsoeng oa mekhoa ea ho penta ka mokhoa o itekanetseng e netefatsa liphetho tse tsitsitseng.

Mohlala, thekenoloji e tsoetseng pele lits'ebetsong tsena e lumella taolo e nepahetseng holim'a lipaterone tsa spray, sekhahla sa phallo le li-angles tsa ts'ebeliso. Boemo bona ba ho ikamahanya le maemo bo etsa hore e be tse loketseng liindasteri tse hlokang lintlha tse hlakileng, joalo ka lisebelisoa tsa elektroniki kapa sefofane. Ho feta moo, bokhoni ba ho pheta-pheta litlhophiso bo netefatsa ho ts'oana ho pholletsa le tlhahiso ea tlhahiso, ho fokotsa tlhoko ea ts'ebetso e theko e boima.

Melemo ea Moshoelella ea Lits'ebetso tsa ho penta ka ho iketsa Spray

Ntle le ho ntlafatsa ts'ebetso le ho nepahala, mekhoa ea ho penta ka mokhoa o itekanetseng kenya letsoho boitekong ba ho tšoarella ka ho fokotsa litšila le tšebeliso ea matla. Mekhoa ea setso hangata e lebisa ho overspray le lisebelisoa tse senyehileng, empa lits'ebetso tsena tse ikemetseng li etselitsoe ho ntlafatsa karolo e 'ngoe le e 'ngoe ea mokhoa oa ho penta.

Ka mohlala, tse ngata mechine e itirisang ea ho penta kenyelletsa likarolo tse tsoetseng pele tsa ho hlaphoheloa le ho li sebelisa hape tse hapang pente e feteletseng le ho e sebelisa hape. Sena ha se fokotse litšila feela empa hape se theola tšusumetso ea tikoloho ea tlhahiso. Ntle le moo, ts'ebeliso e laoloang e fokotsa tlhahiso ea li-volatile organic compounds (VOCs), e thusang bahlahisi ho latela melaoana ea tikoloho le ho fihlela lipheo tsa ts'ebetso ea khoebo.

Ho Ntlafatsa Tšireletseho ea Basebetsi ka Li-sprayers tsa pente tse ikemetseng

Tšireletseho ea basebetsi ke molemo o mong oa bohlokoa oa ho amohela li-sprayers tsa pente tse iketsang. Mekhoa ea ho penta ka letsoho hangata e pepesetsa basebetsi lik'hemik'hale tse kotsi le mosi, e leng ho eketsang kotsi ea mathata a bophelo bo botle. Ka ho iketsetsa mesebetsi ena, likhoebo li ka sireletsa basebetsi ba tsona ha li ntse li boloka tlhahiso.

Sistimi ea ho penta ka boiketsetso e nang le li-conveyors ho matlafatsa polokeho ka ho theha karohano ea 'mele lipakeng tsa basebetsi le ts'ebetso e kotsi. Ka lisebelisoa tse ikemetseng tse sebetsanang le mokhoa oa ho penta, basebetsi ba ka tsepamisa maikutlo mesebetsing e meng sebakeng se sireletsehileng. Phetoho ena ha e fokotse likotsi tsa bophelo bo botle feela empa e boetse e eketsa boitšoaro le khotsofalo mosebetsing.

Ke Hobane'ng ha Mechini ea ho Penta e Ikemetseng ea Spray e le Matsete a Bohlale

Ho tsetela ho mechine ea ho penta ka ho iketsa is not just about improving production processes—it’s also a strategic move for long-term profitability. These systems reduce labor costs, enhance product quality, and optimize resource utilization, providing a significant return on investment.

For industries seeking to remain competitive, the adaptability of these systems is another key advantage. Whether it’s a tsamaiso e feletseng ea ho penta ka ho feletseng kapa seta e hlophisitsoeng haholoanyane, likhoebo li ka etsa litharollo tsa tsona ho fihlela litlhoko tse ikhethileng. Ho feto-fetoha ha maemo ho netefatsa hore lisebelisoa li lula li sebetsa ha litlhoko tsa tlhahiso li ntse li fetoha.

Kamohelo e atileng ea mechine e itirisang ea ho penta is a testament to their transformative impact on industrial production. From enhancing efficiency and precision to supporting sustainability and worker safety, these systems address multiple challenges faced by modern manufacturers. With advancements such as li-sprayers tsa pente tse iketsang le lisistimi tsa ho penta ka boiketsetso tse nang le li-conveyors, likhoebo li ka fihlela boleng bo tsitsitseng ha li ntse li ntlafatsa litšenyehelo le lisebelisoa. Ha liindasteri li ntse li tsoela pele ho etelletsa pele boqapi le botsitso, ho tsetela ho mechine e itirisang ea ho penta ke qeto ea ho nahana pele e netefatsang katleho ea nako e telele.

Lihlahisoa tsa lihlopha

Litaba tsa moraorao

-

Unmatched Mobility and Efficiency in Container Handling Equipment

LitabaJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

LitabaJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

LitabaJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

LitabaJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

LitabaJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

LitabaJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

LitabaMay.28,2025