- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

ਜਨਃ . 13, 2025 12:16

Back To List

crane for container handling

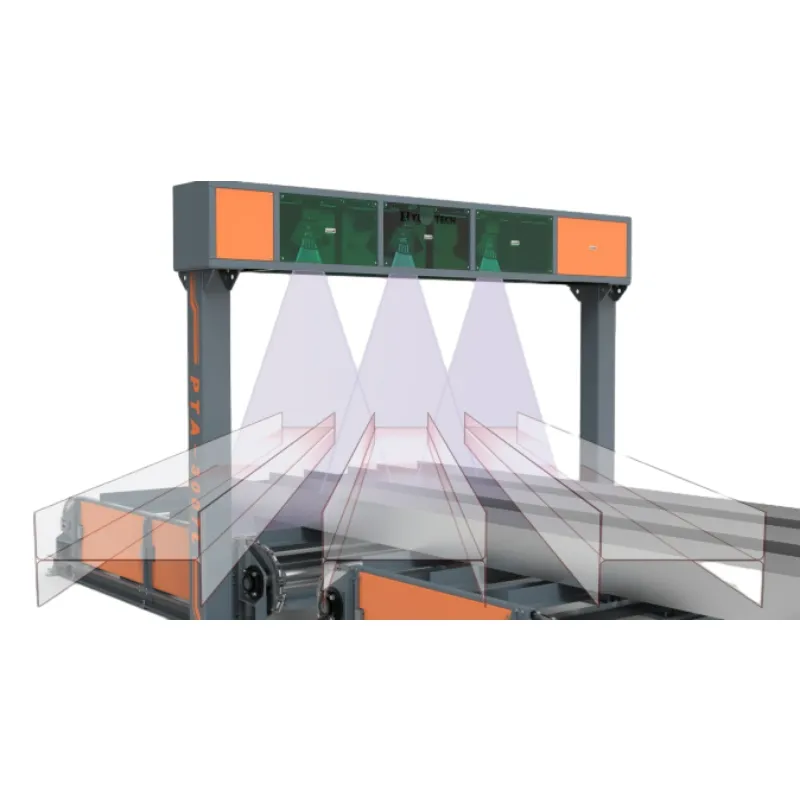

An automatic spray painting system with a conveyor belt represents a pinnacle of innovation in the field of industrial finishing solutions. These systems not only enhance productivity and efficiency, but they also bring a level of consistency and quality to the coating process that is unmatched by manual methods.

Trustworthiness is a crucial factor for users investing in automatic spray painting systems with conveyor belts. Reliability is guaranteed through rigorous testing and adherence to stringent industry standards. Users can trust that these systems will deliver consistent and high-quality results over long periods. Moreover, most manufacturers offer comprehensive support services, including training, installation, and maintenance, ensuring that the systems perform optimally throughout their operational lifecycle. For industries dealing with large volumes and requiring high precision, such as automotive, aerospace, and consumer electronics, these systems are transformative. They offer unparalleled flexibility, allowing for quick changeovers between different product types and reducing production lead times. In conclusion, an automatic spray painting system with a conveyor belt is not just an investment in equipment but an investment in quality, efficiency, and future-proofing industrial operations. The blend of real-world experience, specialized expertise, authoritative industry knowledge, and a commitment to trustworthy practices distinguishes these systems as a gold standard in industrial coating solutions. By leveraging such systems, businesses can significantly enhance their production capabilities, delivering superior products with consistency and precision.

Trustworthiness is a crucial factor for users investing in automatic spray painting systems with conveyor belts. Reliability is guaranteed through rigorous testing and adherence to stringent industry standards. Users can trust that these systems will deliver consistent and high-quality results over long periods. Moreover, most manufacturers offer comprehensive support services, including training, installation, and maintenance, ensuring that the systems perform optimally throughout their operational lifecycle. For industries dealing with large volumes and requiring high precision, such as automotive, aerospace, and consumer electronics, these systems are transformative. They offer unparalleled flexibility, allowing for quick changeovers between different product types and reducing production lead times. In conclusion, an automatic spray painting system with a conveyor belt is not just an investment in equipment but an investment in quality, efficiency, and future-proofing industrial operations. The blend of real-world experience, specialized expertise, authoritative industry knowledge, and a commitment to trustworthy practices distinguishes these systems as a gold standard in industrial coating solutions. By leveraging such systems, businesses can significantly enhance their production capabilities, delivering superior products with consistency and precision.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025