- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

ਜਨਃ . 10, 2025 08:24

Back To List

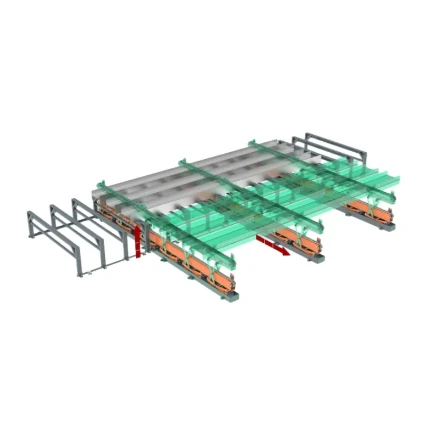

automatic paint spraying robot

The advent of automatic paint spraying robots has revolutionized the surface coating industry, offering unparalleled precision, consistency, and efficiency in applications ranging from automotive to home appliances. These advanced machines employ cutting-edge technology to achieve results that surpass traditional methods, both in quality and cost-effectiveness.

Trustworthiness in the use of automatic paint spraying robots is cultivated through rigorous testing and adherence to industry standards. Quality assurance protocols ensure that these robots perform under a wide range of conditions, delivering consistent results. Companies that invest in robotic painting technology often share case studies and testimonials highlighting substantial gains in productivity and cost savings, enhancing consumer confidence in their products. Real-world experiences demonstrate the transformative impact of these robots across various sectors. For instance, automotive manufacturers report dramatic reductions in paint-related defects and rework costs, attributing them to the robot's high precision and control over paint application parameters. This leads to higher-quality finishes that meet or exceed customer expectations, reinforcing brand loyalty and trust. In conclusion, automatic paint spraying robots are no longer just a futuristic concept but a crucial component of modern manufacturing strategies. They exemplify how technology, when utilized with experience and expertise, can drive industry standards to new heights. As these robots continue to evolve, the potential for further innovation and efficiency gains only solidifies their role as indispensable tools across a multitude of applications.

Trustworthiness in the use of automatic paint spraying robots is cultivated through rigorous testing and adherence to industry standards. Quality assurance protocols ensure that these robots perform under a wide range of conditions, delivering consistent results. Companies that invest in robotic painting technology often share case studies and testimonials highlighting substantial gains in productivity and cost savings, enhancing consumer confidence in their products. Real-world experiences demonstrate the transformative impact of these robots across various sectors. For instance, automotive manufacturers report dramatic reductions in paint-related defects and rework costs, attributing them to the robot's high precision and control over paint application parameters. This leads to higher-quality finishes that meet or exceed customer expectations, reinforcing brand loyalty and trust. In conclusion, automatic paint spraying robots are no longer just a futuristic concept but a crucial component of modern manufacturing strategies. They exemplify how technology, when utilized with experience and expertise, can drive industry standards to new heights. As these robots continue to evolve, the potential for further innovation and efficiency gains only solidifies their role as indispensable tools across a multitude of applications.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025