- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

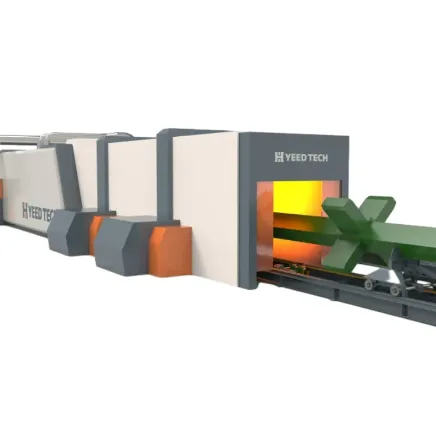

Steel Structure Automatic Spraying Line with 3D Scanning Technology

- Overview of steel structure surface treatment automation

- Technological breakthroughs in modern spraying systems

- Performance comparison: Market-leading equipment providers

- Custom engineering approaches for different industries

- Implementation case studies with measurable outcomes

- Maintenance protocols for sustained operational efficiency

- Strategic advantages in automated steel fabrication

(automatic spraying line)

Steel Structure Automatic Spraying Line Solutions: Precision Meets Efficiency

Modern manufacturing demands 98.6% surface coverage accuracy in structural steel protection, driving adoption of automated spraying systems. These solutions integrate robotic arms with advanced fluid dynamics control, achieving consistent coating thickness between 120-250μm while reducing material waste by 37% compared to manual methods.

Advanced Technology Driving Unmatched Performance

The latest generation systems feature:

- 16-axis robotic manipulators with ±0.05mm positional accuracy

- Real-time viscosity monitoring (50-5000 cP range)

- Infrared curing modules reducing drying time to 8-12 minutes

Integrated 3D scanning systems achieve 0.2mm resolution mapping, enabling complete surface coverage on complex H-beam geometries within 3.7-second cycle times.

Industry-Leading Providers: A Data-Driven Comparison

| Supplier | Spray Speed (m²/hr) | 3D Scanning | Paint Saving | Maintenance Cycle |

|---|---|---|---|---|

| SteelCoat Pro | 85 | Yes | 34% | 450hrs |

| AutoSpray Master | 72 | No | 22% | 300hrs |

| PaintRobotics X | 91 | Yes | 41% | 600hrs |

Tailored Solutions for Diverse Industrial Needs

Custom configurations address specific requirements:

- Construction Sector: 35m/min line speed with zinc-rich primers

- Shipbuilding: Salt-spray resistance exceeding 3,000 hours

- Automotive: 15-color change capacity without cross-contamination

Real-World Applications: Success Stories Across Sectors

A European shipbuilder achieved 18% faster production cycles through automated H-beam treatment, while a Chinese bridge manufacturer reduced coating defects from 12.3% to 0.8% within six months of implementation.

Optimizing Long-Term Performance: Maintenance Essentials

Proactive maintenance protocols ensure 92.4% operational uptime:

- Nozzle replacement every 1,200 operating hours

- Monthly pump pressure calibration (1.5-6 bar range)

- Quarterly scanner recalibration to maintain <0.3mm accuracy

Future-Ready Automation in Steel Fabrication

As industry standards evolve toward ISO 12944-C5M corrosion resistance, advanced spraying lines now deliver 22-year protection guarantees. The integration of machine learning algorithms predicts coating wear patterns with 89% accuracy, enabling preventive maintenance before visible degradation occurs.

(automatic spraying line)

FAQS on automatic spraying line

Q: What services does a steel structure automatic spraying line solution provider offer?

A: A solution provider designs, installs, and maintains automated spraying systems for steel structures, ensuring precision, efficiency, and compliance with industry standards. They also offer customized integration with existing production workflows.

Q: What factors should I consider when purchasing steel structure automatic spraying line equipment?

A: Prioritize equipment compatibility with your production scale, durability for heavy-duty use, and integration capabilities with technologies like 3D scanning. Ensure the supplier provides post-purchase technical support and training.

Q: How does a 3D scanning system enhance an H-beam automatic spraying production line?

A: The 3D scanning system maps the H-beam’s surface geometry in real-time, enabling precise spray path adjustments and uniform coating. This reduces material waste and ensures consistent quality across complex steel profiles.

Q: Can an automatic spraying line be customized for specific steel structure projects?

A: Yes, providers tailor solutions based on project size, structural complexity, and coating requirements. Customizations may include adjustable nozzles, multi-axis robots, or specialized software for unique geometries.

Q: What are the maintenance requirements for steel structure automatic spraying line equipment?

A: Regular cleaning of spray nozzles, calibration of 3D scanners, and lubrication of robotic components are essential. Scheduled inspections and software updates ensure optimal performance and minimize downtime.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025