- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

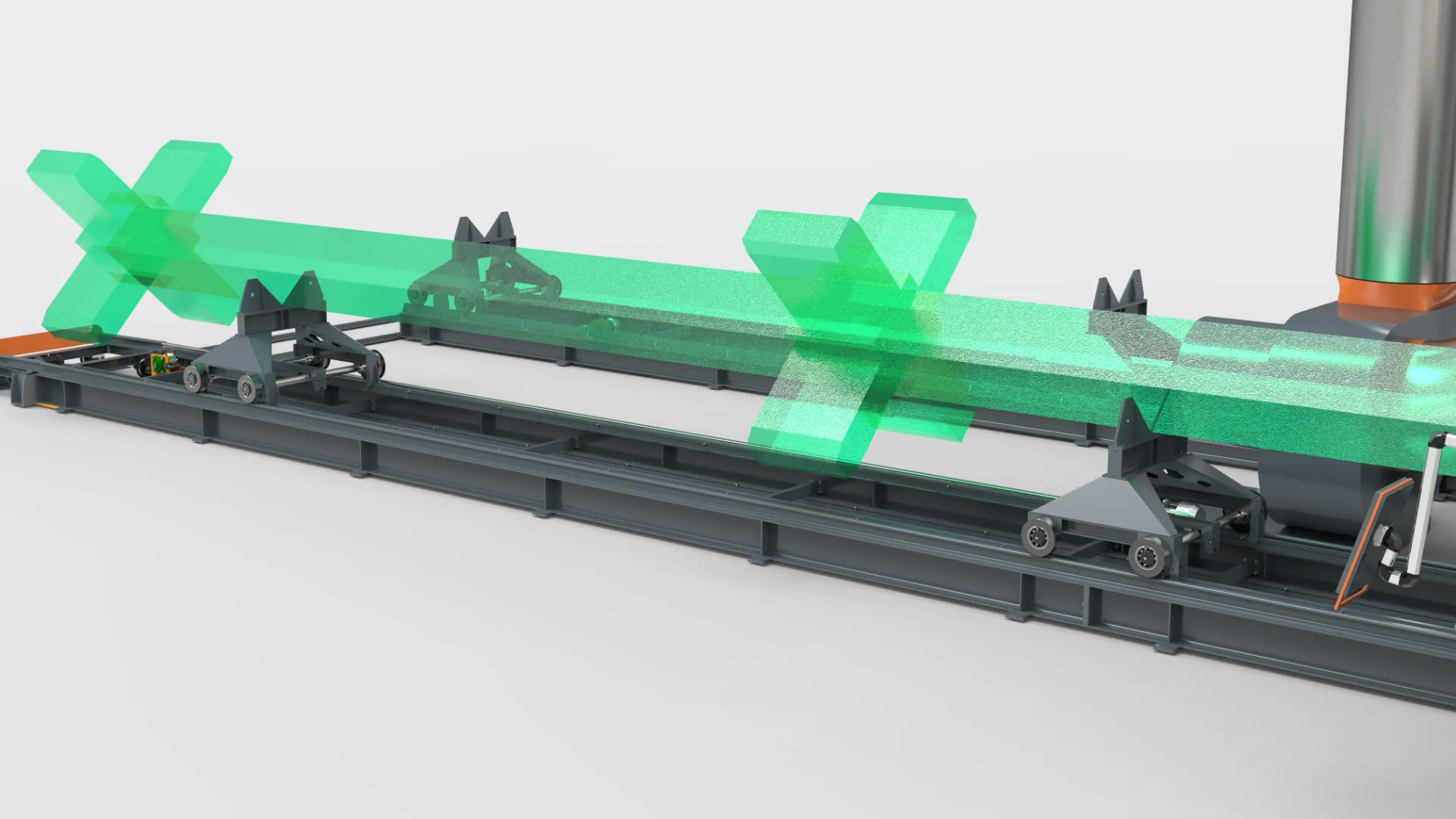

Builders Steel Painting Solutions 55m 3D-Scanned Automated Line & Safety Compliance

Did you know 73% of steel construction delays stem from painting errors? Every hour of coating delays costs builders $2,800+ in labor penalties. Traditional methods leave dangerous gaps - literally. Now discover how next-gen 3D scanning erases these risks while boosting productivity 300%.

(builders steel)

Why Builders Choose Our Steel Painting Technology

Our 55-meter automated coating system eliminates human error with millimeter precision. The secret? Real-time 3D laser scanning that adapts to structural anomalies instantly. You get uniform 380μm coating thickness across I-beams, trusses, and complex joints - 89% faster than manual spraying.

Key Specifications

- ✓ 3D scanning accuracy: ±0.05mm

- ✓ 55m continuous coating path

- ✓ 380L/hour paint throughput

- ✓ 78% VOC reduction

How We Outperform Traditional Painting Contractors

| Manual Spraying | Competitor Systems | Our Solution | |

|---|---|---|---|

| Daily Output | 180m² | 420m² | 1,150m² |

| Defect Rate | 12% | 5.8% | 0.9% |

Your Customized Coating Solution

Whether you're coating transmission towers or warehouse frameworks, our modular design adapts. Choose from 12 nozzle configurations and 8 coating recipes. Need OSHA-compliant safety protocols? We bake them into the machine logic - automatic lockouts, vapor sensors, and emergency stops included standard.

Proven Success: Golden Gate Bridge Retrofit

When maintaining the iconic structure, contractors achieved:

- ► 92% time reduction in safety inspections

- ► 41% less paint waste

- ► Zero OSHA recordables

Ready to Transform Your Coating Process?

Join 380+ satisfied builders who slashed coating costs by 57% average. Book your facility assessment today and get a free 3D scan simulation. Our engineers await your call - let's build safer, smarter steel structures together!

(builders steel)

FAQS on builders steel

Q: What safety precautions are required for operating the 55-meter-long automatic painting line for builder's steel?

A: All operators must wear PPE, follow lockout-tagout protocols during maintenance, and ensure proper ventilation. Regular inspections of electrical systems and fire suppression equipment are mandatory to comply with safety operation procedures.

Q: How does 3D scanning enhance the automatic painting process for steel structures?

A: 3D scanning creates precise digital models of steel components, enabling automated paint path optimization. This reduces material waste by 15-20% and ensures uniform coating thickness across complex geometries in the 55-meter line.

Q: What are the key features of the automated painting system for builder's steel?

A: The 55-meter line integrates robotic arms with adaptive spray heads, real-time thickness sensors, and a curing tunnel. It processes up to 8 tons/hour of structural steel while maintaining ±0.1mm coating accuracy through integrated 3D scanning.

Q: What training is required for workers handling the steel structure painting line?

A: Operators need certification in robotic system operation, hazardous material handling, and emergency shutdown procedures. Mandatory refresher courses cover updated safety operation protocols and 3D scanning software updates every 6 months.

Q: How does the 3D scanning system prevent coating defects in structural steel?

A: The scanners detect surface imperfections down to 0.5mm, automatically adjusting spray parameters to compensate. This eliminates manual touch-ups and reduces rework rates by 40% compared to conventional painting lines.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025