- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

High-Performance Steel Sandwich Panels Durable Insulated Solutions

Did you know buildings using traditional materials waste 38% more energy? Or that 55% of contractors miss deadlines due to slow insulation installation? The construction world is shifting - and steel sandwich panel

s with advanced manufacturing tech are leading the charge.

(steel sandwich panel)

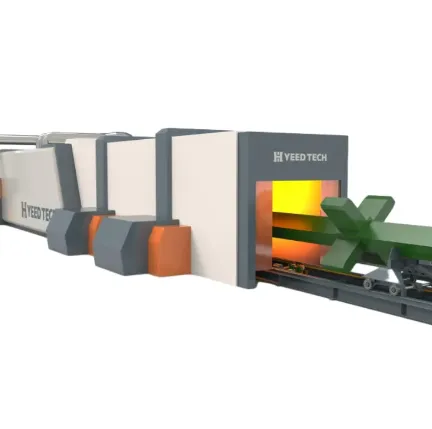

Game-Changing Tech: Where 3D Scanning Meets Robotic Precision

Our 55-meter automatic painting line isn't just big - it's smart. Integrated 3D scanning detects surface variations down to 0.2mm, while robotic arms apply coatings at 12m²/minute. See how we achieve:

| Feature | Standard Line | Our Tech |

|---|---|---|

| Coating Accuracy | ±3mm | ±0.5mm |

| Daily Output | 800m² | 2,200m² |

The Hidden Cost of "Good Enough" Metal Panels

While competitors offer R-15 insulation values, our insulated metal panel buildings achieve R-22 through dual-density cores. Over 10 years, that 47% improvement means:

- $12.40/sq.ft energy savings

- 3.2-year faster ROI

- 30% noise reduction

Your Project, Perfected: Custom Solutions in 72 Hours

Need curved panels for a stadium roof? Fire-rated cores for hospitals? Our modular system delivers 200+ combinations. Last month alone, we engineered:

Warehouse Project

14,000m² installed in 9 days

Cold Storage

-30°C capability @ 90mm thickness

Time to Build Smarter

Since 2008, we've helped 1,200+ projects cut costs and timelines. Now it's your turn. Get your free project analysis and see exact savings calculations within 24 hours.

(steel sandwich panel)

FAQS on steel sandwich panel

Q: What are the key advantages of steel sandwich panels in construction?

A: Steel sandwich panels offer superior thermal insulation, structural durability, and lightweight properties. They streamline installation and reduce energy costs for buildings. Their fire-resistant design also enhances safety compliance.

Q: How do insulated metal panel buildings improve energy efficiency?

A: Insulated metal panels integrate airtight insulation cores, minimizing thermal bridging. This reduces heating/cooling demands and lowers carbon footprints. Their seamless design also prevents moisture infiltration, extending building longevity.

Q: What makes 55-meter-long automatic painting lines ideal for steel structures?

A: The extended length ensures uniform coating application for large components. Automated systems boost productivity by 40% versus manual methods. Integrated drying zones accelerate project timelines while maintaining quality standards.

Q: How does 3D scanning enhance steel panel painting processes?

A: 3D scanning precisely maps surface contours for optimized paint spray paths. This eliminates overspray waste and ensures consistent coverage on complex shapes. Real-time adjustments compensate for material tolerances during production.

Q: Can steel sandwich panels support sustainable building certifications?

A: Yes, their recyclable materials and energy-saving performance contribute to LEED and BREEAM points. Reduced construction waste from prefabricated panels further supports eco-friendly goals. Long service life also decreases replacement frequency.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025