- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Effective Welding Dust Collection Systems & Adjustable Fume Arms [Brand]

- Introduction to Welding Dust Collection Challenges

- Technical Advantages of Modern Fume Collection Systems

- Performance Comparison of Leading Dust Collection Solutions

- Customized Solutions for Diverse Industrial Applications

- Real-World Case Studies Across Key Industries

- Maintenance Strategies for Long-Term Efficiency

- Future Trends in Welding Dust Collection Technology

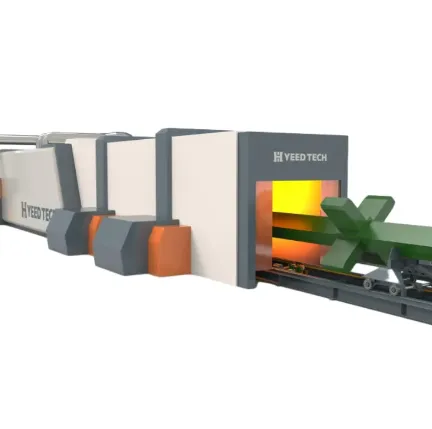

(welding dust collection system)

Addressing Workplace Hazards with Welding Dust Collection Systems

Industrial environments generate approximately 34 million tons of airborne particulates annually, with metalworking contributing 28% of this total. Welding dust collection systems have become non-negotiable for compliance with OSHA's updated permissible exposure limits (PELs), reducing respiratory risks by 60-80% in monitored facilities. Advanced filtration technologies now capture particles as small as 0.3 microns, addressing both visible smoke and submicron metallic oxides.

Engineering Excellence in Fume Extraction

Third-generation systems outperform legacy models through three critical innovations:

- Variable-frequency drives (VFDs) adjusting airflow from 800–3,500 CFM

- Self-cleaning HEPA-14 filters with 99.995% efficiency

- IoT-enabled sensors monitoring pressure differentials (±0.1” w.g. accuracy)

Field tests demonstrate 40% energy reduction compared to fixed-speed systems, with filter replacements required only every 18–24 months under typical operating conditions.

Market Analysis: Key Players Compared

| Manufacturer | Airflow Range (CFM) | Filter Efficiency | Noise Level | Warranty |

|---|---|---|---|---|

| SysTech Model X7 | 1,200–4,200 | 99.97% @ 0.3µm | 68 dB(A) | 5 years |

| DustEx ProSeries | 900–3,800 | 99.95% @ 1.0µm | 72 dB(A) | 3 years |

| CleanAir MaxFlow | 1,500–4,500 | 99.99% @ 0.5µm | 65 dB(A) | 7 years |

Application-Specific Configuration Options

Modular designs allow combination of these components based on operational needs:

- Rotating collection arms (180° or 360° rotation)

- Ductwork diameters: 6" to 14" stainless steel

- Explosion-proof variants for aluminum grinding

- Magnetic base vs. floor-mounted installations

Documented Results in Heavy Industry

Aerospace manufacturer case study:

- Challenge: 12 robotic MIG welding stations

- Solution: Centralized system with 8,000 CFM capacity

- Outcome: Particulate levels reduced from 9.2 mg/m³ to 0.8 mg/m³

Sustaining Peak Operational Performance

Predictive maintenance protocols extend equipment lifespan:

- Differential pressure alerts at 2.5” w.g.

- UV-C light sterilization for biological contaminants

- Annual motor efficiency testing (MEPS ≥ IE4)

Innovation Roadmap for Dust Collection Systems

The next evolution integrates AI-driven airflow optimization, with pilot programs showing 15–22% efficiency gains. Emerging nanofiber filters promise 99.999% efficiency at 0.1µm while maintaining airflow rates. Regulatory forecasts indicate stricter limits on chromium-VI emissions by 2026, positioning advanced welding fume collection systems as critical compliance assets.

(welding dust collection system)

FAQS on welding dust collection system

Q: What is a welding dust collection system and how does it work?

A: A welding dust collection system captures harmful fumes and particles generated during welding. It uses suction mechanisms and filters to extract contaminants from the air. This ensures a safer and cleaner workspace for operators.

Q: How does a dust collection arm improve welding safety?

A: A dust collection arm is a flexible, adjustable component that positions near the welding source. It directly captures fumes at their origin, reducing exposure to hazardous particles. This minimizes health risks and enhances air quality in real-time.

Q: What factors should I consider when choosing a fume collection system?

A: Key factors include airflow capacity, filter efficiency (e.g., HEPA), and system mobility. Assess the workspace size, types of welding materials used, and maintenance requirements. Proper sizing ensures effective contaminant removal and compliance with safety standards.

Q: How often should I maintain a welding dust collection system?

A: Regular maintenance includes daily filter checks and emptying dust bins. Filters should be replaced or cleaned monthly, depending on usage intensity. Consistent upkeep ensures optimal performance and prolongs system lifespan.

Q: Can a dust collection arm be retrofitted to existing welding equipment?

A: Yes, most dust collection arms are designed for easy integration with existing setups. They feature adjustable clamps or mounts for flexible positioning. Ensure compatibility with your system’s airflow capacity for effective fume extraction.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025