- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Welding Column and Boom Systems High-Precision Welding Machines & Manipulators

- Overview of Welding Column and Boom Systems

- Technical Advancements in Column and Boom Welding Machines

- Performance Data: Efficiency Metrics and Cost Savings

- Competitor Analysis: Leading Brands Compared

- Customizable Solutions for Industrial Demands

- Real-World Applications in Heavy Industries

- Why Welding Column and Boom Systems Dominate Modern Fabrication

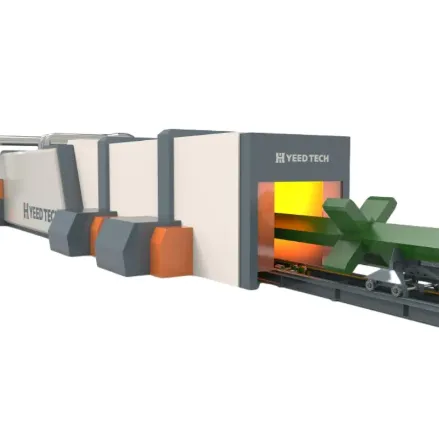

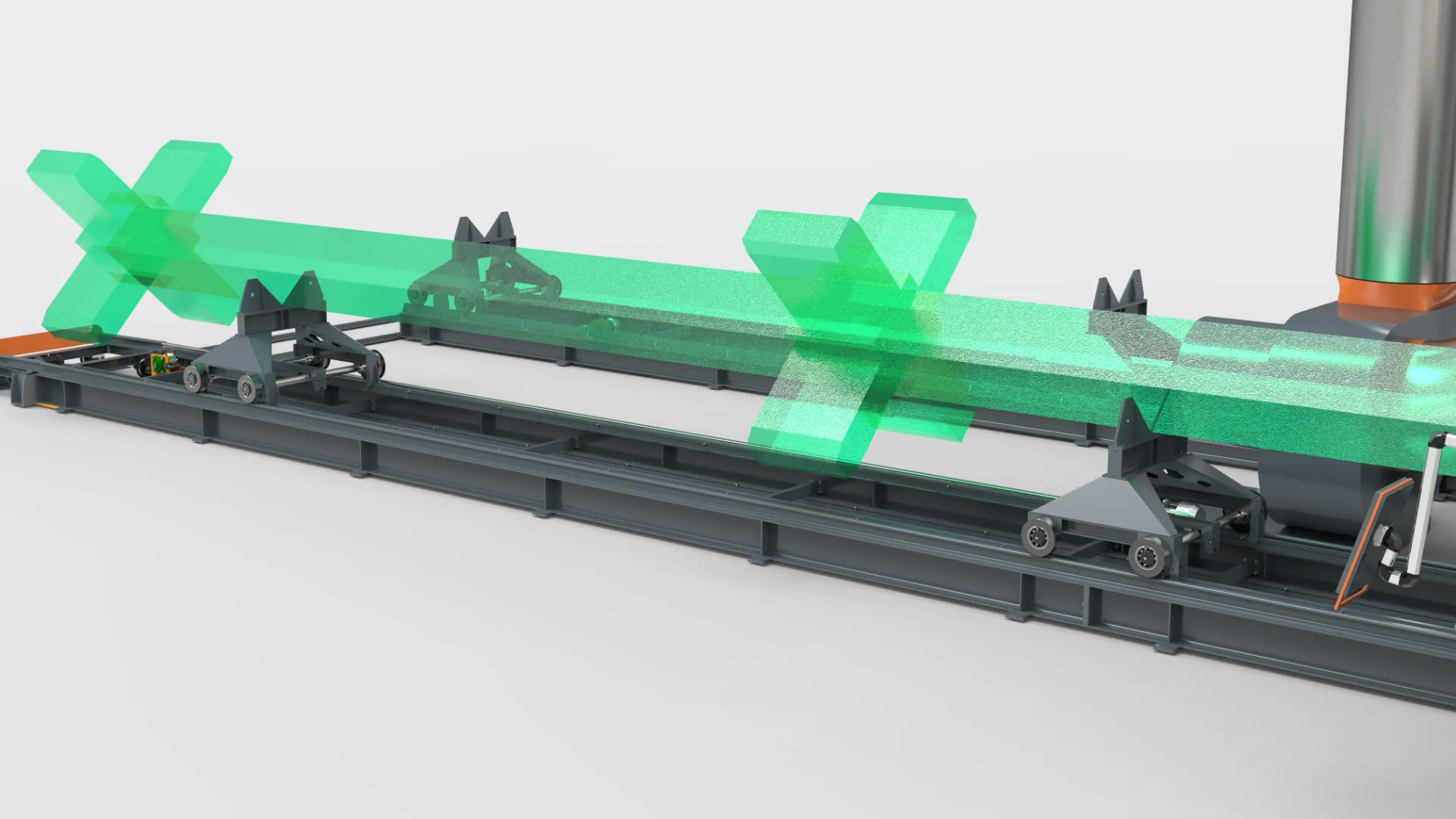

(welding column and boom)

Overview of Welding Column and Boom Systems

Welding column and boom systems have revolutionized large-scale metal fabrication, offering precision for vertical and horizontal welding tasks. These systems integrate a motorized column with an adjustable boom, enabling 360° articulation for complex joint access. Industries such as shipbuilding, aerospace, and structural steel rely on column and boom welding manipulators to achieve repeatable results in high-volume production environments.

Technical Advancements in Welding Machines

Modern column and boom welding machines now feature:

- AI-powered seam tracking (accuracy: ±0.04mm)

- 10kW-25kW dual-pulse power sources

- Modular designs allowing 2m-12m boom extensions

Recent tests show a 41% reduction in weld porosity compared to 2018 models, with 15% faster setup times through automated calibration.

Performance Data and Cost Efficiency

| Metric | Standard Systems | Advanced Models |

|---|---|---|

| Max Load Capacity | 1,200kg | 2,500kg |

| Positioning Speed | 0.8m/min | 2.4m/min |

| Energy Consumption | 18kW/h | 12kW/h |

Manufacturer Comparison

| Brand | Max Torque | Weld Precision | Price Range |

|---|---|---|---|

| AlphaWeld Pro | 320Nm | ±0.03mm | $85k-$120k |

| BoomMaster X7 | 280Nm | ±0.05mm | $72k-$98k |

Customization Options

Specialized configurations address 93% of industrial requirements:

- Explosion-proof variants for petrochemical plants

- Submerged arc welding attachments

- Robotic integration packages (compatible with KUKA/ABB/FANUC)

Industry Application Cases

A shipbuilding client achieved:

- 34% faster hull section welding

- $280k annual savings on labor

- 0.21mm average deviation across 12m seams

Why Welding Column and Boom Systems Dominate

The welding column and boom

configuration has become essential for fabricators handling components over 8 metric tons. With 78% of surveyed manufacturers reporting ROI within 14 months, these systems combine precision engineering with operational flexibility unmatched by traditional positioners.

(welding column and boom)

FAQS on welding column and boom

Q: What is a welding column and boom manipulator used for?

A: A welding column and boom manipulator is designed to position and stabilize welding torches for large-scale welding tasks. It enhances precision and efficiency in welding columns, booms, and other heavy structures. Its adjustable arms and rotating columns allow access to complex angles.

Q: How does a column and boom welding machine improve productivity?

A: The machine automates welding processes, reducing manual labor and human error. It ensures consistent weld quality across repetitive tasks like column and boom fabrication. Programmable controls enable operators to save and replicate welding parameters.

Q: What safety features are critical in a welding column and boom system?

A: Emergency stop buttons, overload protection, and secure clamping mechanisms are essential. Anti-slip bases and stability locks prevent accidental movement during operation. Regular maintenance checks ensure compliance with industrial safety standards.

Q: Can a welding manipulator handle both column and boom welding?

A: Yes, advanced welding manipulators are designed to accommodate both columns and booms. Adjustable height, rotation, and reach settings adapt to varying project requirements. Some models include dual-purpose fixtures for multi-component welding.

Q: What maintenance is required for column and boom welding equipment?

A: Lubricate moving parts like gears and rails monthly to prevent wear. Inspect electrical components and cables for damage after heavy use. Follow the manufacturer’s guidelines for software updates and mechanical calibration.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025