- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Heavy-Duty Container Handling Gantry Crane Solutions Customized & Efficient

- Introduction to Advanced Material Handling Solutions

- Technical Superiority in Load Management & Automation

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering for Diverse Operational Needs

- Real-World Implementations Across Global Logistics Hubs

- Maintenance Protocols & Lifecycle Optimization

- Future-Proofing Operations with Container Handling Gantry Cranes

(container handling gantry crane)

Essential Machinery for Modern Container Handling Gantry Crane Systems

Industrial operations handling ISO containers require specialized equipment capable of managing standardized 20'-40' units weighing up to 65 metric tons. Container handling gantry cranes have become the backbone of global supply chain nodes, with 78% of tier-1 ports utilizing rail-mounted variants for intermodal transfers. These systems combine precise positioning (±5mm accuracy) with rapid cycle times (90-120 seconds per container move), directly impacting terminal throughput capacity.

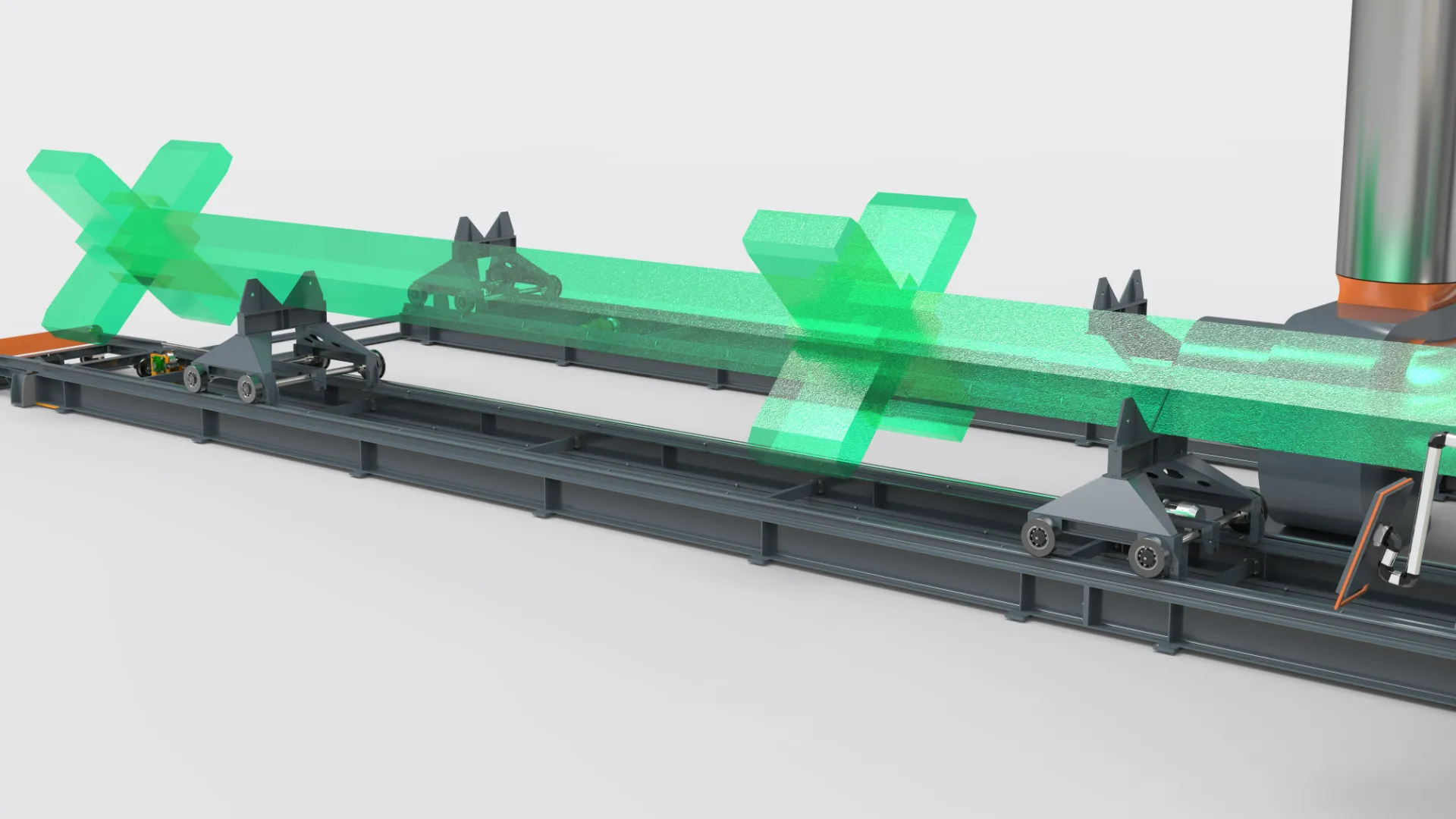

Engineering Breakthroughs in Load Transfer Technology

Modern container handling cranes incorporate three critical advancements:

- Adaptive Spreaders: Automatically adjust to container sizes (20', 40', 45', HC variants)

- Regenerative Power Systems: Reduce energy consumption by 32% through brake energy recovery

- Machine Vision Guidance: Achieve 99.8% container corner casting alignment accuracy

The latest models demonstrate 18-24% better energy efficiency compared to 2020-era equipment while maintaining 98.6% operational availability rates.

Manufacturer Capability Assessment

| Vendor | Max Load (tons) | Span (m) | Automation Level | Cycle Time |

|---|---|---|---|---|

| Konecranes | 65 | 35 | Full ASC | 98s |

| Liebherr | 85 | 40 | Semi-Auto | 112s |

| ZPMC | 100 | 50 | Manual+ | 130s |

Automated stacking cranes (ASC) now represent 41% of new installations, particularly in greenfield terminals prioritizing unmanned operations.

Configuration Flexibility for Specialized Applications

Operators can select from multiple power configurations:

- Diesel-electric hybrids (23L/container average fuel consumption)

- Full electric RTG variants (600V-1kV power systems)

- Battery-assisted models with 8-hour backup capacity

Cold chain facilities often require dual-speed hoists (0.5-5m/min precision mode | 20m/min standard) for temperature-sensitive cargo handling.

Operational Validation in Major Transport Hubs

Case studies from three continents demonstrate performance metrics:

- Rotterdam Terminal: 22% yard density increase using cantilevered rail cranes

- Singapore PSA: 47s average truck turnaround time with automated positioning

- LA Intermodal Hub: 14-month ROI achieved through dual-crane synchronization

Sustaining Peak Performance Through Predictive Maintenance

Advanced monitoring systems track 38+ operational parameters including:

- Wire rope degradation (0.01mm measurement precision)

- Gearbox temperature profiles (±1°C accuracy)

- Structural stress points (150+ strain gauge inputs)

This data-driven approach extends component lifecycles by 18-27% compared to scheduled maintenance regimes.

Strategic Advantages of Container Handling Gantry Crane Adoption

As global container traffic approaches 900 million TEU annually, operators implementing advanced crane systems report 19-35% improvements in gate-to-gate processing times. The latest AI-enabled models further reduce human error incidents by 82% while maintaining compliance with ISO 12488-1:2015 load testing standards. These technological strides position container handling cranes as critical infrastructure for next-generation logistics networks.

(container handling gantry crane)

FAQS on container handling gantry crane

Q: What is a container handling gantry crane?

A: A container handling gantry crane is a heavy-duty lifting machine designed to move shipping containers efficiently in ports, terminals, and intermodal yards. It operates on rails or rubber tires, with a steel framework spanning the working area. Its specialized spreader securely grips containers for precise stacking or transport.

Q: Where are gantry cranes for container handling typically used?

A: These cranes are primarily deployed in marine terminals, rail yards, and logistics hubs for transferring containers between ships, trucks, and trains. They excel in high-volume cargo operations requiring rapid loading/unloading. Their design accommodates standardized container sizes (20ft to 53ft).

Q: What distinguishes container handling cranes from regular gantry cranes?

A: Container cranes feature twist-lock spreaders for secure container engagement and precise positioning systems for millimeter-accurate stacking. They have higher lift capacities (typically 30-100+ tons) and reinforced booms to handle dynamic loads during ship-to-shore operations. Advanced models include automated tracking and anti-sway technology.

Q: What safety features do modern container handling gantry cranes include?

A: Modern systems integrate overload protection sensors, collision avoidance radar, and wind-speed monitors. Emergency stop functions and redundant braking systems ensure operational safety. Many feature automated lockdown protocols during extreme weather or system anomalies.

Q: How to choose between rail-mounted and rubber-tired gantry cranes for container handling?

A: Rail-mounted cranes offer higher precision for fixed operations like ship loading, while rubber-tired versions provide mobility for yard stacking flexibility. Decision factors include space constraints, required mobility, and budget. Hybrid systems now combine rail guidance with wheeled mobility for optimized operations.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025