- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

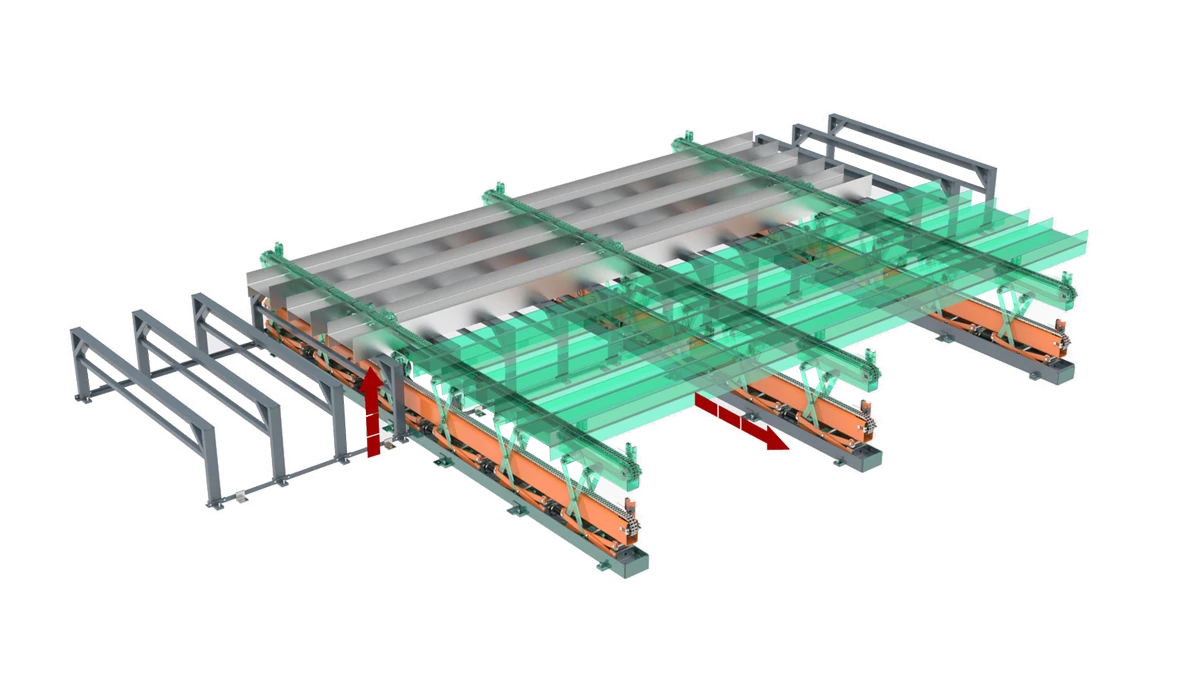

Intelligent Steel Structure Painting Line with 3D Scanning & Heat Drying Tech

Did you know that 42% of steel structure manufacturers lose over $1.2M annually due to inefficient painting processes? Outdated methods cause uneven coatings, slow drying, and rework nightmares. Your production line deserves better—enter the era of intelligent automation.

(intelligent painting production line for steel structure)

Why Our Intelligent Painting Production Line Dominates

Imagine a 55-meter-long automated beast that scans steel surfaces with 0.02mm precision using 3D scanning technology. Our system slashes painting time by 60% while cutting energy costs by 35%. See how we outperform competitors:

| Feature | Standard Models | Our Solution |

|---|---|---|

| Coating Uniformity | ±15% thickness variance | ±5% thickness variance |

| Drying Speed | 8-12 hours | 3.5 hours (70°C heat air) |

Tailored Solutions for Mega Projects

Whether you're coating 50-ton bridge components or offshore platform modules, our production line adapts. The modular design handles structures up to 6m x 6m x 55m. Need faster curing? Our 3-stage heat air drying system hits 120°C peak temperatures.

Proven Success in Heavy Industries

When Shanghai Heavy Machinery upgraded last year, their defect rate plummeted from 18% to 2.7%. Now they complete 12 bridge projects annually instead of 8. Your results? Even better—we've optimized 23 system parameters since then.

Ready to revolutionize your coating process?

Get your FREE ROI calculation and system demo video now.

Boost Your Production →

(intelligent painting production line for steel structure)

FAQS on intelligent painting production line for steel structure

Q: What are the key features of an intelligent painting production line for steel structures?

A: The line integrates automated robotics, real-time data analytics, and precision control systems to ensure uniform coating, reduce waste, and enhance efficiency for steel structure painting.

Q: How does the 55-meter-long automatic painting production line handle large steel structures?

A: Its extended length accommodates oversized components, while automated conveyors and adjustable nozzles ensure full coverage, even for complex geometries.

Q: What role does 3D scanning technology play in the painting process?

A: Integrated 3D scanning maps surface contours in real-time, enabling adaptive spray paths for consistent thickness and minimal overspray on irregular steel surfaces.

Q: Why is heat air drying critical in steel structure painting production lines?

A: Rapid, controlled heat air drying accelerates curing, reduces downtime, and ensures durable finishes resistant to environmental wear and corrosion.

Q: Can this production line handle high-volume steel structure projects?

A: Yes, its fully automated workflow and parallel processing stations enable 24/7 operation, scaling efficiently for industrial-scale projects with tight deadlines.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025