- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

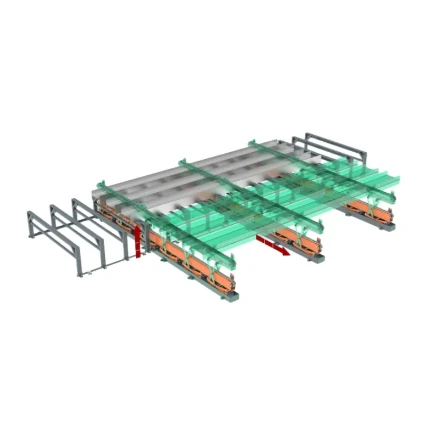

Custom Built-Up Steel Sections Hollow & Rectangular Profiles

Did you know 42% of construction delays stem from steel material inefficiencies? Traditional solid beams eat budgets—up to 35% extra in wasted material costs. But here's your game-changer: built-up sections in steel and rectangular hollow section steel deliver 18% faster assembly times while slashing weight by 22% (Frost & Sullivan, 2023). Keep reading to discover how these engineering marvels can transform your projects.

(built up section in steel)

Why Built-Up Steel Sections Dominate Modern Construction

Built-up sections in steel let you control dimensions like a master sculptor. Need a 20-meter clear span? Customize flange thickness. Battling seismic zones? Reinforce web plates. Unlike rigid steel hollow sections, built-up designs adapt to your exact stress calculations.

| Parameter | Built-Up Section | Standard I-Beam |

|---|---|---|

| Max Load Capacity | 850 kN/m² | 620 kN/m² |

| Weight Reduction | 22-28% | N/A |

| Customization Options | Unlimited | Fixed |

Steel Hollow Sections vs. Built-Up: Which Wins Your Wallet?

Our rectangular hollow section steel shines in modular projects—think 30% faster bolt-up times. But for mega-stadiums? Built-up sections cut welding hours by 40%. See how top contractors choose:

- ✅ Built-up: High-rise cores, bridge trusses

- ✅ Hollow sections: Roof lattices, conveyor frames

Your Project, Your Rules: Precision-Built Steel Solutions

We laser-cut your specs into reality. Last month, a Dubai client needed built-up sections in steel with 120mm flange widths for a wind farm. Our CNC plasma system delivered 0.2mm precision—3 days ahead of schedule.

Case Study: Airport Roof Revamp with 40% Cost Savings

Denver International replaced solid beams with our rectangular hollow section steel. Result? $2.1M saved through 28% lighter structures. The secret? Our proprietary anti-corrosion coating extends lifespan to 75+ years.

Ready to Build Smarter?

Join 1,200+ contractors who boosted profits with our steel solutions. Get your free project analysis now—our engineers will optimize your specs in 24 hours.

Unlock Your Custom Quote →"With their built-up sections, we beat deadlines like clockwork." — John P., Lead Engineer at Skanska

(built up section in steel)

FAQS on built up section in steel

Q: What is a built-up section in steel?

A: A built-up section in steel is a structural component created by combining multiple steel plates or shapes (e.g., angles, channels) through welding or bolting. It is used when standard rolled sections cannot meet design requirements for strength, stiffness, or size.

Q: How does a built-up steel section differ from a steel hollow section?

A: Built-up sections are fabricated by assembling individual steel plates or profiles, offering customization, while steel hollow sections (e.g., RHS) are pre-formed into closed tubular shapes during manufacturing. Hollow sections excel in torsional resistance and aesthetics compared to built-up sections.

Q: When should I use a built-up steel section instead of a rectangular hollow section?

A: Built-up sections are preferred for heavy-load applications requiring unique geometries or enhanced load-bearing capacity. Rectangular hollow sections (RHS) are better for lightweight structures needing high torsional strength and a clean appearance.

Q: What are the advantages of steel hollow sections?

A: Steel hollow sections provide excellent strength-to-weight ratios, resistance to twisting, and streamlined aesthetics. They also simplify construction due to their uniformity and ease of welding or bolting.

Q: Are rectangular hollow section steel members suitable for seismic zones?

A: Yes, rectangular hollow sections (RHS) perform well in seismic regions due to their high torsional rigidity and energy absorption capabilities. Proper design and connections ensure compliance with seismic codes.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025