- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

જાન્યુઆરી . 19, 2025 03:18

Back To List

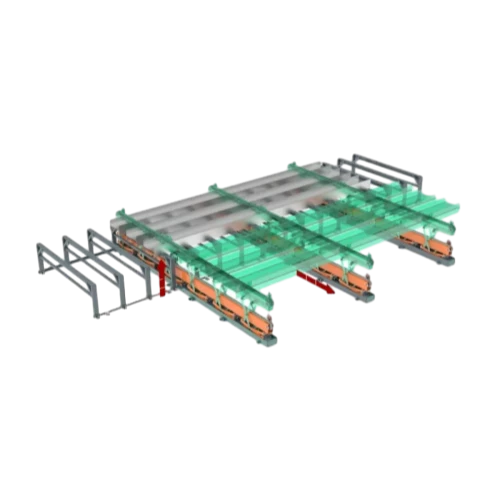

crane for container handling

In the world of modern manufacturing and production, the evolution of automated processes has brought about revolutionary changes, particularly in the domain of painting. The concept of an automated painting process not only enhances efficiency but also provides a level of precision and quality that manual operations can rarely match. This article delves into the facets of automated painting processes, examining their benefits, mechanisms, and cutting-edge innovations, to provide a comprehensive understanding for those considering implementing such systems.

Another critical advantage lies in the environmental impact. Traditional painting operations often lead to significant overspray and harmful emissions. Automated systems, however, employ high-efficiency transfer technologies and enclosed systems that minimize waste and environmental hazards. This is not only beneficial for the planet but also aligns with stringent regulatory standards, fostering a sustainable brand image for businesses. Industry experts and market leaders who have adopted automated painting report lower operational costs and higher throughput rates. This investment, although significant initially, offers long-term returns via reduced material use, diminished labor costs, and enhanced product turnaround times. Moreover, the integration of IoT devices and data analytics into these systems allows for predictive maintenance, minimizing downtime and prolonging equipment life. The credibility of automated painting solutions is bolstered by extensive research and development. Leading manufacturers collaborate with academic institutions and research bodies to push the boundaries of what these systems can achieve. Trials and case studies provide robust evidence of the performance benefits and ROI, reassuring stakeholders and decision-makers of the viability of such innovations. In conclusion, as the industrial landscape continues to embrace automation, painting processes are undeniably at the forefront of this transformation. The synthesis of robotic technology, real-time analytics, and sustainable practices creates a compelling case for adoption. Businesses aspiring to remain competitive and efficient in an increasingly demanding market will find substantial value in these automated solutions. They not only meet the requirements of precision and speed but also exhibit a responsible approach towards environmental stewardship, ensuring an economically and ecologically sustainable future in manufacturing.

Another critical advantage lies in the environmental impact. Traditional painting operations often lead to significant overspray and harmful emissions. Automated systems, however, employ high-efficiency transfer technologies and enclosed systems that minimize waste and environmental hazards. This is not only beneficial for the planet but also aligns with stringent regulatory standards, fostering a sustainable brand image for businesses. Industry experts and market leaders who have adopted automated painting report lower operational costs and higher throughput rates. This investment, although significant initially, offers long-term returns via reduced material use, diminished labor costs, and enhanced product turnaround times. Moreover, the integration of IoT devices and data analytics into these systems allows for predictive maintenance, minimizing downtime and prolonging equipment life. The credibility of automated painting solutions is bolstered by extensive research and development. Leading manufacturers collaborate with academic institutions and research bodies to push the boundaries of what these systems can achieve. Trials and case studies provide robust evidence of the performance benefits and ROI, reassuring stakeholders and decision-makers of the viability of such innovations. In conclusion, as the industrial landscape continues to embrace automation, painting processes are undeniably at the forefront of this transformation. The synthesis of robotic technology, real-time analytics, and sustainable practices creates a compelling case for adoption. Businesses aspiring to remain competitive and efficient in an increasingly demanding market will find substantial value in these automated solutions. They not only meet the requirements of precision and speed but also exhibit a responsible approach towards environmental stewardship, ensuring an economically and ecologically sustainable future in manufacturing.

Prev:

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025