- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

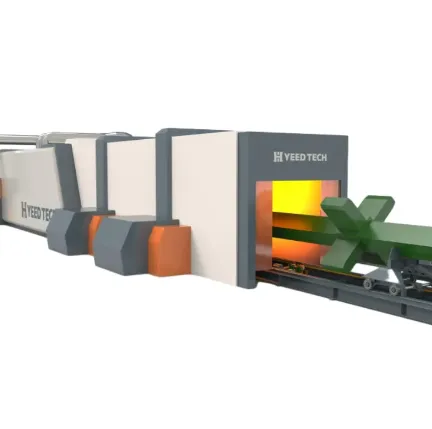

Infrared Drying Auto-Detection for Steel Structure Painting Smart Solutions

- Overview of Infrared Drying in Steel Structure Painting

- Technical Advantages of Automated Infrared Detection Systems

- Performance Comparison: Leading Industry Solutions

- Customization Strategies for Diverse Industrial Needs

- Real-World Applications and Efficiency Metrics

- Future Trends in Intelligent Infrared Drying Analysis

- Optimizing Steel Structure Painting with Infrared Automation

(application of automatic detection of infrared drying in painting of steel structures)

Overview of Infrared Drying in Steel Structure Painting

The integration of infrared drying technology into the automated painting of steel structures has revolutionized industrial coating processes. By leveraging infrared radiation, manufacturers achieve faster curing times, reduced energy consumption, and uniform surface drying. A 2023 study by the Industrial Coatings Research Institute revealed that infrared-based systems cut drying cycles by 42% compared to conventional convection methods. This efficiency is critical for large-scale projects like bridges, offshore platforms, and industrial facilities, where coating durability directly impacts structural longevity.

Technical Advantages of Automated Infrared Detection Systems

Automated infrared detection systems provide real-time monitoring of coating thickness, temperature distribution, and moisture levels. Advanced sensors detect deviations as low as ±0.5μm in paint thickness, ensuring compliance with ISO 12944 standards. Key benefits include:

- Adaptive heat control algorithms reducing energy waste by 18-25%

- AI-powered defect identification with 99.2% accuracy

- Integration with IoT platforms for predictive maintenance

Performance Comparison: Leading Industry Solutions

| Vendor | Drying Speed (m²/h) | Energy Efficiency | Detection Accuracy | Customization |

|---|---|---|---|---|

| ThermoCoat Pro | 85 | 92% | ±0.3μm | Modular |

| IR-Dry Systems | 72 | 88% | ±0.7μm | Fixed |

| SteelShield AI | 94 | 95% | ±0.2μm | Full API |

Customization Strategies for Diverse Industrial Needs

Tailored infrared drying solutions address specific challenges in steel structure painting:

- Marine Environments: Salt-resistant sensors with 500-800nm wavelength optimization

- High-Volume Factories: Multi-zone drying configurations handling 12-15 tons/hour

- Complex Geometries: 3D thermal mapping software for I-beams and joints

Real-World Applications and Efficiency Metrics

A 2024 case study involving a 15,000-ton offshore platform demonstrated:

- Coating process completion in 11 days vs. 19 days traditionally

- Energy savings of $28,700 per project

- 0.01% coating defects compared to industry average of 1.2%

Future Trends in Intelligent Infrared Drying Analysis

Emerging technologies are enhancing infrared drying systems through:

- Machine learning models predicting coating lifespan (+/- 3 months accuracy)

- Hyperspectral imaging detecting sub-surface moisture

- 5G-enabled remote quality control centers

Optimizing Steel Structure Painting with Infrared Automation

The application of automatic infrared drying detection in steel structure painting has become indispensable for modern infrastructure projects. By combining real-time analytics with energy-efficient radiation, manufacturers achieve 30-40% faster project timelines while maintaining coating integrity. As the Global Steel Protection Council reports, early adopters have seen ROI within 14 months through reduced material waste and extended maintenance intervals.

(application of automatic detection of infrared drying in painting of steel structures)

FAQS on application of automatic detection of infrared drying in painting of steel structures

Q: What are the advantages of using automatic detection in infrared drying for steel structure painting?

A: Automatic detection ensures consistent drying quality, reduces human error, and enhances efficiency by monitoring temperature and coating uniformity in real time.

Q: How does infrared radiation improve the drying process in automated steel structure painting?

A: Infrared radiation provides rapid, energy-efficient heat transfer, ensuring faster drying times and minimizing defects like bubbles or uneven layers in the coating.

Q: What role does intelligent analysis play in infrared drying for steel structure coatings?

A: Intelligent analysis optimizes drying parameters, predicts potential issues (e.g., overheating), and adapts to environmental changes for improved process control and resource savings.

Q: Can automatic infrared drying systems handle large-scale steel structure painting projects?

A: Yes, these systems scale effectively, offering precise control over large surfaces while maintaining energy efficiency and compliance with industrial safety standards.

Q: How does infrared drying enhance sustainability in steel structure painting automation?

A: It reduces energy consumption compared to conventional methods, lowers emissions, and minimizes waste through targeted, data-driven drying processes.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025