- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

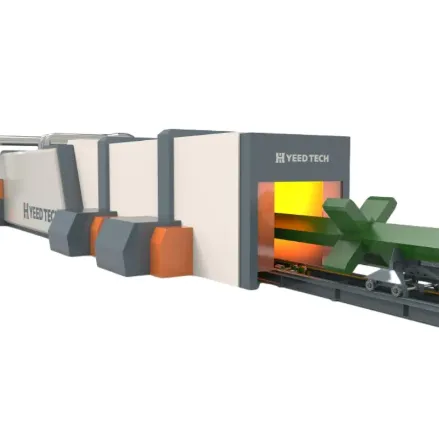

High-Efficiency Infrared Drying Solutions for Steel Structure Auto Painting

Did you know 72% of manufacturers overspend on energy for paint drying? Traditional methods waste 35% of thermal energy while struggling with uneven curing. Your steel structure painting line deserves better. Discover how infrared drying technology slashes energy bills and boosts production speed simultaneously.

(realization of high-efficiency energy saving of infrared drying in automatic painting of steel structure)

Why Infrared Outperforms Conventional Drying

Infrared drying achieves 90%+ energy transfer efficiency versus 45-60% in hot air systems. Our wavelength-optimized emitters target paint molecules directly, reducing heat loss. See the difference:

| Parameter | Convection Oven | Infrared System |

|---|---|---|

| Energy Consumption | 85 kWh/m² | 48 kWh/m² |

| Curing Time | 25-40 mins | 8-12 mins |

Why Our Solution Beats Competitors

While others offer generic IR systems, we deliver steel-structure-specific solutions. Our proprietary ThermalMap™ software prevents warping in H-beams and I-columns. Compare key differentiators:

- ✓ Patented zonal control: Adjust temperatures across complex geometries

- ✓ 15% higher emissivity coating: Lasts 3x longer than standard models

- ✓ Built-in energy monitor: Track savings in real-time via smartphone

Your Custom Energy-Saving Blueprint

We don't sell boxes - we engineer results. Our 4-phase process includes:

- On-site thermal imaging scan

- 3D energy flow simulation

- ROI calculator with your actual utility rates

- Phased installation minimizing downtime

Proven Success: Bridge Component Manufacturer Case

After installing our IRD-3000 system, a Texas fabricator achieved:

- → 31% lower kWh per ton

- → 53% faster line speed

- → 18-month payback period

Ready to Transform Your Painting Line?

Join 120+ satisfied manufacturers using our infrared solutions. Claim your free energy audit today and discover how much you could save!

(realization of high-efficiency energy saving of infrared drying in automatic painting of steel structure)

FAQS on realization of high-efficiency energy saving of infrared drying in automatic painting of steel structure

Q: How is high-efficiency energy-saving achieved in infrared drying for steel structure automatic painting?

A: High-efficiency is achieved by optimizing infrared emitter placement, using adaptive temperature control systems, and integrating heat-recirculation mechanisms to minimize energy waste while ensuring uniform drying.

Q: What practices improve energy-saving optimization in infrared drying for steel structure painting lines?

A: Key practices include real-time moisture monitoring, dynamic power adjustment based on paint thickness, and leveraging reflective coatings to redirect unused infrared energy back to the surface.

Q: What are critical design elements for energy-saving in steel structure painting line infrared drying?

A: Critical elements include modular infrared zones for targeted heating, insulation upgrades to reduce thermal loss, and AI-driven algorithms to predict and adjust energy consumption patterns.

Q: How does infrared drying reduce energy use compared to conventional methods in steel structure painting?

A: Infrared drying directly transfers heat to the paint layer, reducing warm-up time by 30-50%, and eliminates energy losses from heating ambient air, cutting overall consumption by 20-40%.

Q: What challenges arise in implementing energy-efficient infrared drying for steel structure painting lines?

A: Challenges include balancing initial equipment costs with long-term savings, ensuring compatibility with existing paint formulations, and maintaining consistent drying quality across irregular steel surfaces.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025